Cleaning and drying machine for medical apparatus and instruments

A medical device and dryer technology, applied in the medical field, can solve the problems of low efficiency, time-consuming and laborious, inability to clean multiple devices at the same time, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

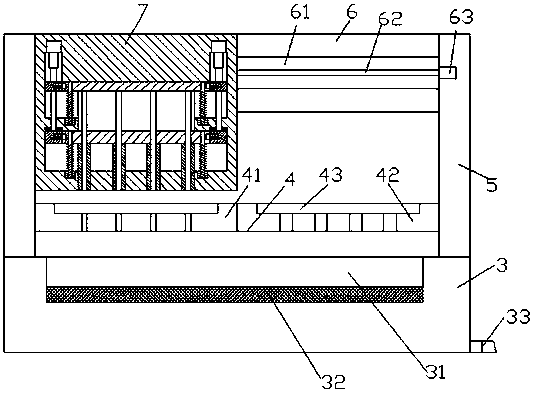

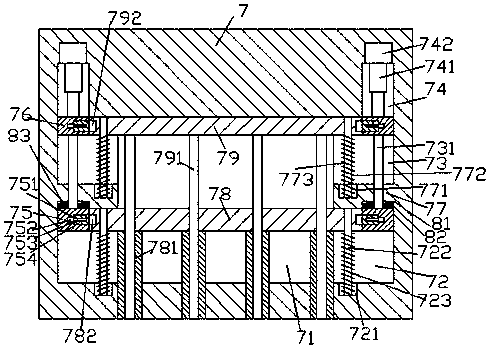

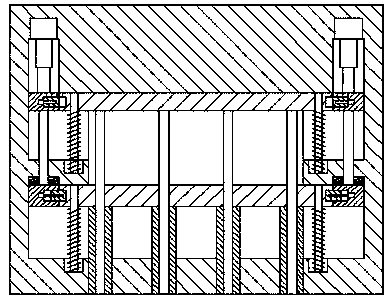

[0025] Such as Figure 1-Figure 8 As shown, a medical device cleaning and drying machine of the present invention includes a frame body and a cleaning and drying device 7. A cavity 71 is provided inside the cleaning and drying device 7, and the left and right sides of the cavity 71 are mutually called. There are a first sliding connection groove 73, a baffle plate 77 and a second sliding connection groove 72, and a first sliding connection rod 79 extending left and right is arranged above the cavity 71, and the first sliding connection rod 79 is elongated left and right The ends are inserted into the first sliding joint grooves 73 on the left and right sides respectively and are connected by sliding joints. A second sliding joint rod 78 extending from the left and right is provided below the cavity 71. The second sliding joint rod 78 78, the left and right elongated tails are inserted into the second sliding joint groove 72 on the left and right sides respectively and are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com