A shearing rocker mechanism with a magnetic attraction device

A technology of rocker mechanism and magnetic suction device, which is applied in the direction of transmission device, aircraft transmission device, aircraft power device, etc., can solve the problems of collision, metal stretching at the gap, and the influence of the movement rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

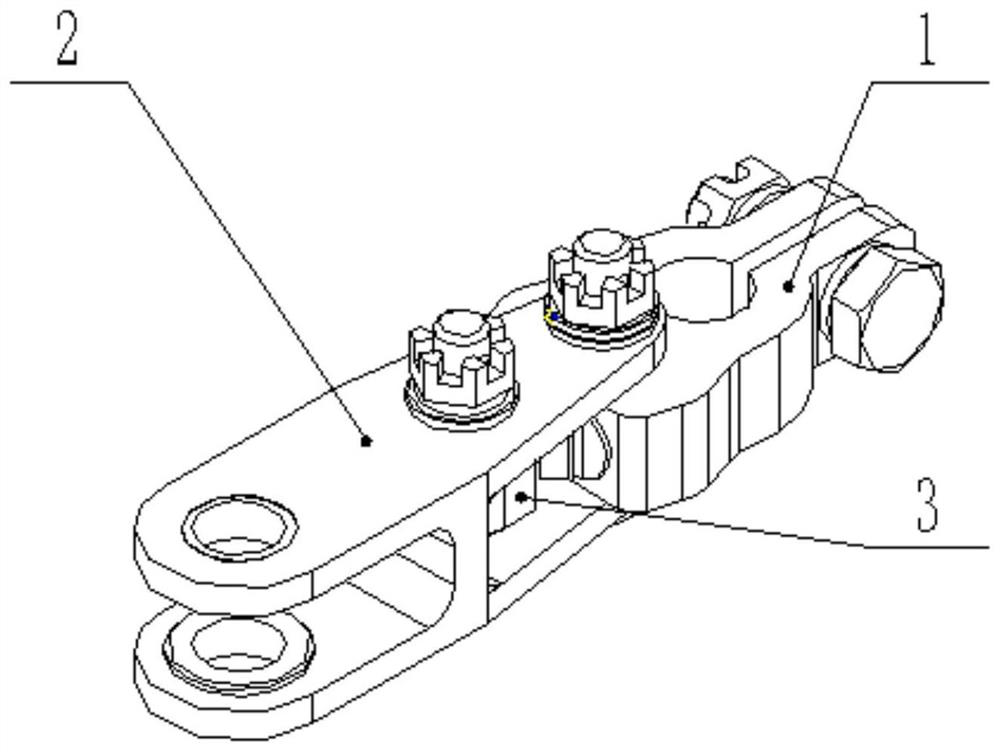

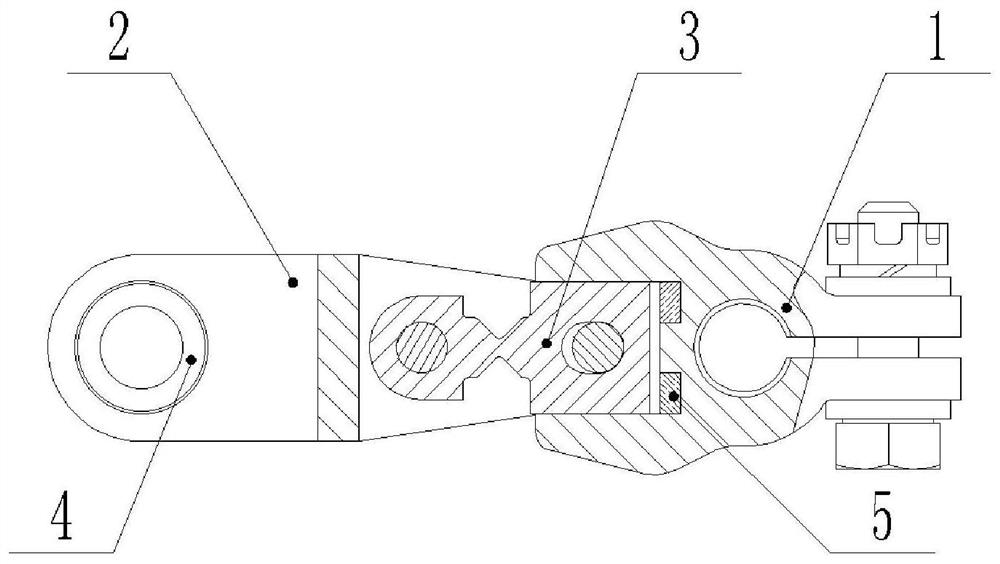

[0016] Attached below Figure 1-2 , the present invention is further described:

[0017] The rocker arm connection block 3 is installed in the opening of the rocker arm connection block 1, and the shear block 3 is matched with the opening of the rocker arm connection block 1 to facilitate the installation and disassembly of the shear block 3, wherein the magnetic steel 5 is bonded to the rocker arm connection At the bottom of the hole in the block 1, the shear block 3 is installed in the hole, and there is a 1mm movable gap between the low end and the magnetic steel 5. The material of the shear block 3 is steel with magnetic properties.

[0018] Among them, the rocker arm connecting block is provided with an internal spline for connecting with the outer spline shaft, and a magnetic steel and standard parts for fastening the outer spline shaft are installed in the rocker arm connecting block. One end of the rocker arm connecting block has a The opening for installing the shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com