Continuous positioning system and method

A positioning system and station technology, applied in labels, packaging, labeling machines, etc., can solve problems such as difficult and precise positioning, and achieve the effect of low error rate, high error tolerance rate, and ensuring time and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

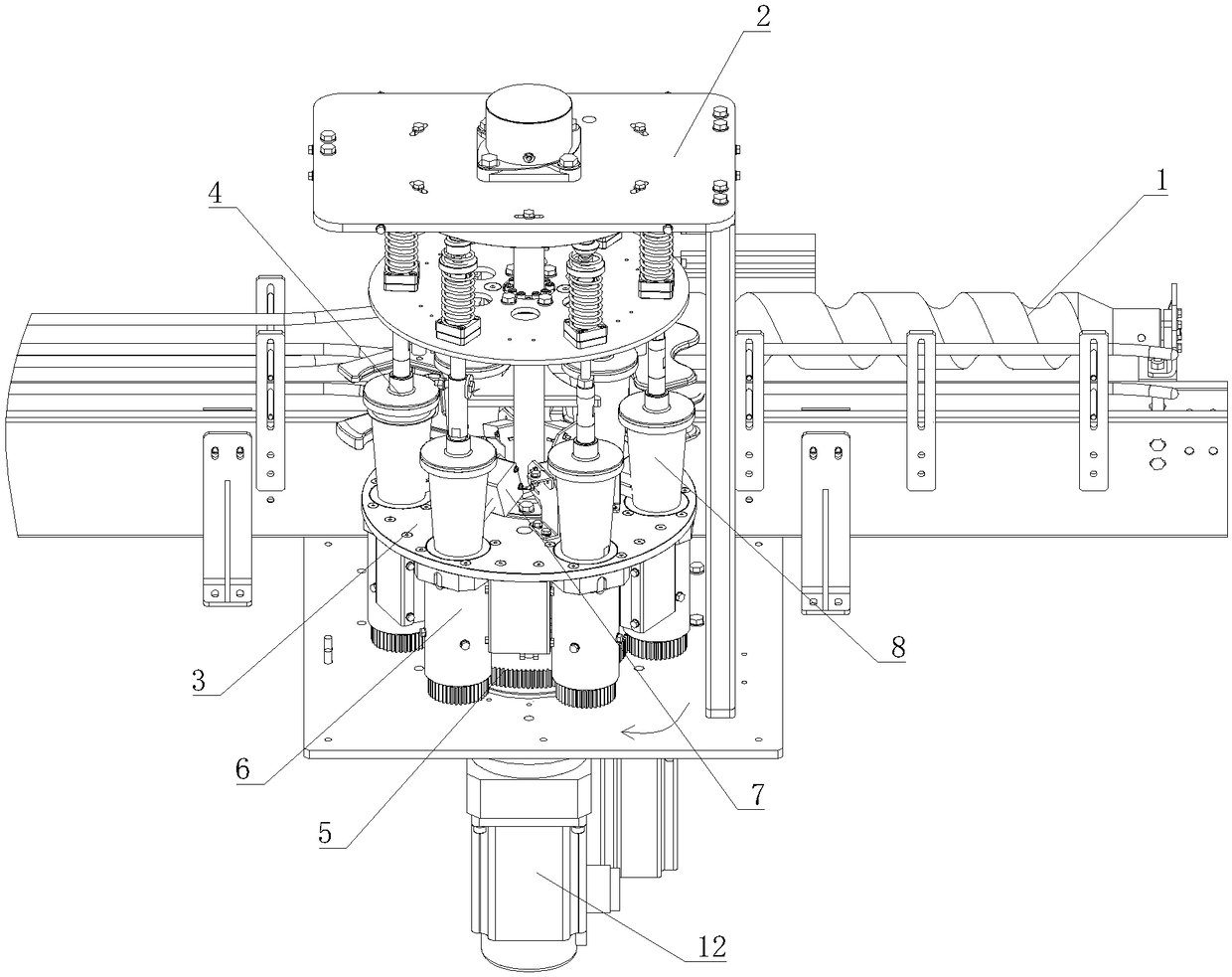

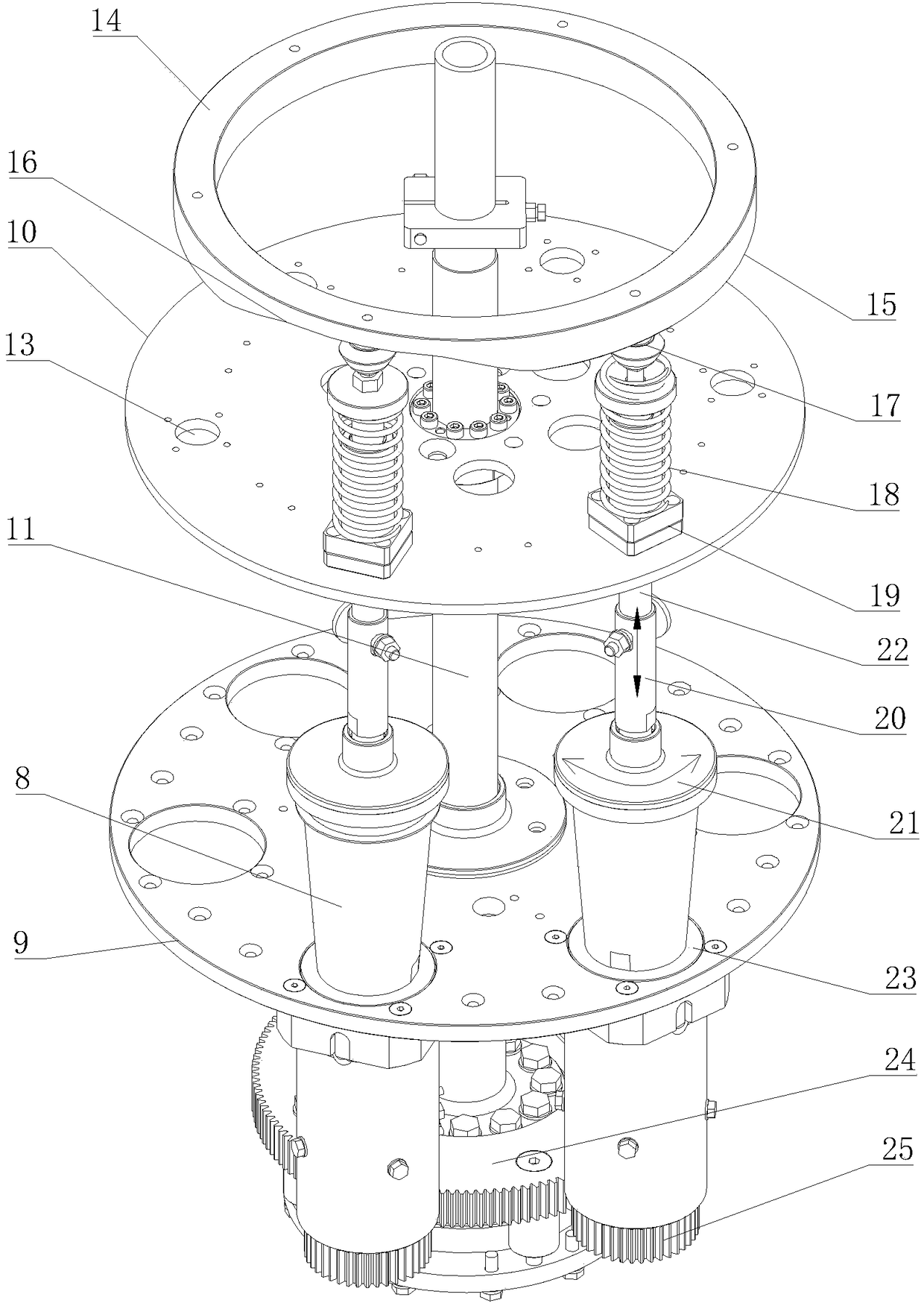

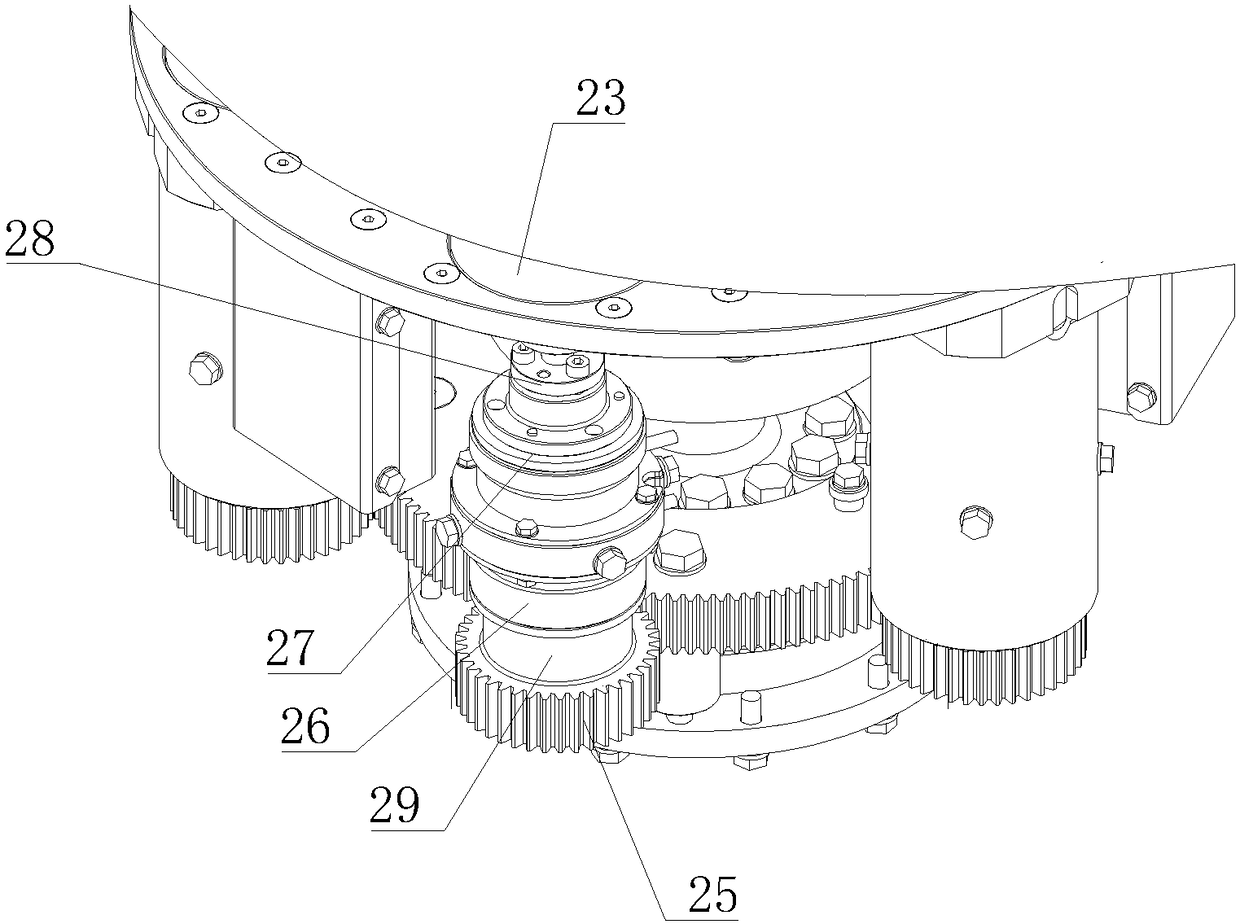

[0033] Such as figure 1 As shown, a continuous positioning system includes a product conveying device 1, a main frame 2, a turntable device 3 installed in the main frame 2, a cup pressing device 4, a cup rotating device 5, a brake clutch device 6, and a color mark detection device 7; the turntable device 3 is provided with six circumferentially arranged circular hole-shaped stations 8; the product conveying device 1 is used to send products with color codes into the station 8 of the turntable device 3, The cup pressing device 4 is used to axially compress the products entering the turntable device 3; the cup rotating device 5 is used to drive the compacted products to rotate; the color mark detection device 7 is used to It is used to detect the color mark of the product in rotation; the brake clutch device 6 is used to make the rotor device 5 instantly stop the self-rotation movement of the product when the color mark detection device 7 detects a color mark signal. Such as ...

Embodiment 2

[0035] A continuous positioning method, its specific steps are as follows:

[0036] Step 1. The product conveying device 1 arranges the products with color codes on the surface in an orderly manner and then sends them to the station 8 of the turntable device 3;

[0037] Step 2. Compress and position the product sent to the station 8 by the cup pressing device 4 and rotate the product by the cup device 5 on the station 8; at the same time, the turntable device 3 drives the station 8 to revolve;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com