Cooking oil plastic packaging bottle

A technology for packaging bottles and edible oil, applied in the directions of packaging, transportation and packaging, bottles, etc., can solve the problems of occupation, reduce the effective capacity of packaging bottles, inconvenient to dump edible oil, etc., and achieve the effect of high rigidity and convenient and fast combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

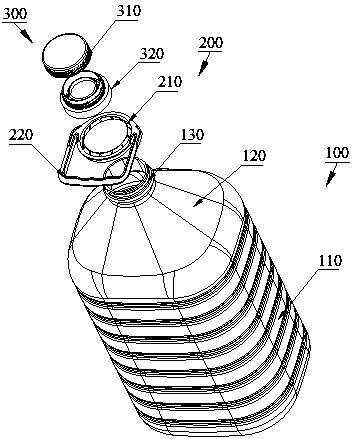

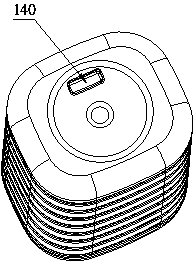

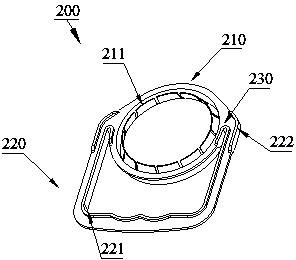

[0031] Such as Figures 1 to 9As shown, a plastic packaging bottle for edible oil includes a main body 100 of the packaging bottle. Cover 300 and handle 200, the bottle mouth 130 is connected with the bottle body 110 through the bottle shoulder 120, the bottle bottom 140 is fixed on the bottom of the bottle body 110, the handle 200 includes a handle ring 220 and a handle ring 220 and fastened on the ring 210 at the junction of the bottle mouth 130 and the bottle shoulder 120, the ring 210 is provided with a filter 326, the bottom 140 of the bottle is a concave structure facing the bottle mouth, and on it An inset grip 140 for lifting the bottom of the bottle is provided. The indented grip portion 140 is disposed on the bottom of the bottle close to the side of the bottle body.

[0032] Such as image 3 As shown, the inner wall of the handle ring 220 is provided with inner reinforcing ribs 221 for increasing the contact area with human hands. The handle ring 220 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com