Monitoring device for detecting pressure of adhesive conveying pipe and defoaming system of adhesive

A technology for conveying pipelines and monitoring systems, applied in spinning solution degassing, filament forming treatment, textiles and papermaking, etc., can solve the problems of viscose waste, pollution, flow instability, etc., to reduce the waste of human resources, The effect of avoiding environmental pollution and reducing cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

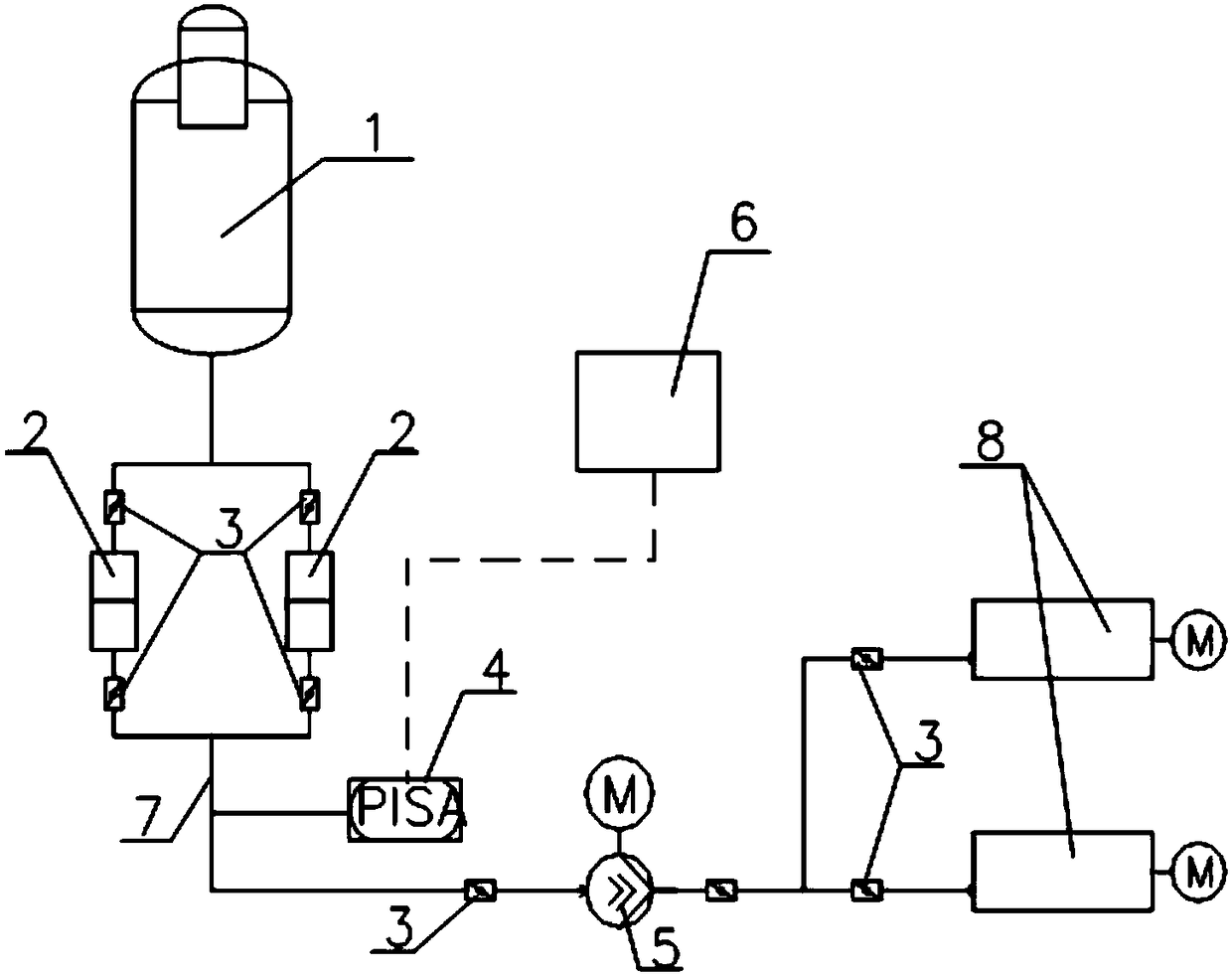

[0020] Such as figure 1 As shown, this embodiment relates to a monitoring device for detecting the pressure of the viscose conveying pipeline, and the two ends of the viscose conveying pipeline 7 are respectively connected to the liquid outlet end of the tank filter 2 and the liquid inlet end of the viscose pump 5 , including a pressure monitoring system 6 and a pressure gauge 4 for detecting the pressure in the viscose delivery pipeline 7, the pressure gauge 4 is electrically connected to the pressure monitoring system 6, and transmits the detected pressure information to the pressure monitoring system 6, so The pressure monitoring system 6 monitors the pressure information detected by the pressure gauge 4 in real time, and judges whether the tank filter 2 needs to be cleaned according to the pressure information.

[0021] On the basis of the above embodiments, it can also be specifically defined that the pressure monitoring system 6 is preset with an alarm value, and the pre...

Embodiment 2

[0029] Such as figure 1 As shown, the present embodiment relates to a viscose defoaming system, comprising a defoaming bucket 1, a tank filter 2, a viscose pump 5 and a filter device 8, the liquid inlet end of the tank filter 2 is connected to the The defoaming barrel 1 is connected to receive the viscose from the defoaming barrel 1, and the liquid outlet end of the tank filter 2 is connected to the liquid inlet end of the viscose pump 5 through the viscose delivery pipeline 7 , the liquid outlet of the viscose pump 5 is connected to the liquid inlet of the filter device 8 , and also includes a monitoring device for detecting the pressure of the viscose delivery pipeline 7 .

[0030] In a more specific embodiment, there are two tank filters 2 connected in parallel.

[0031] Two parallel canister filters 2 can increase the processing capacity of viscose, and when the pressure detection system 6 judges that the canister filter 2 needs to be cleaned, one can be closed first for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com