Intelligent extractor hood and control method thereof

A technology of intelligent range hoods and range hoods, which is applied in the fields of oil fume removal, heating methods, and household heating, etc. Adjustment and other issues to achieve the effect of high intelligence and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

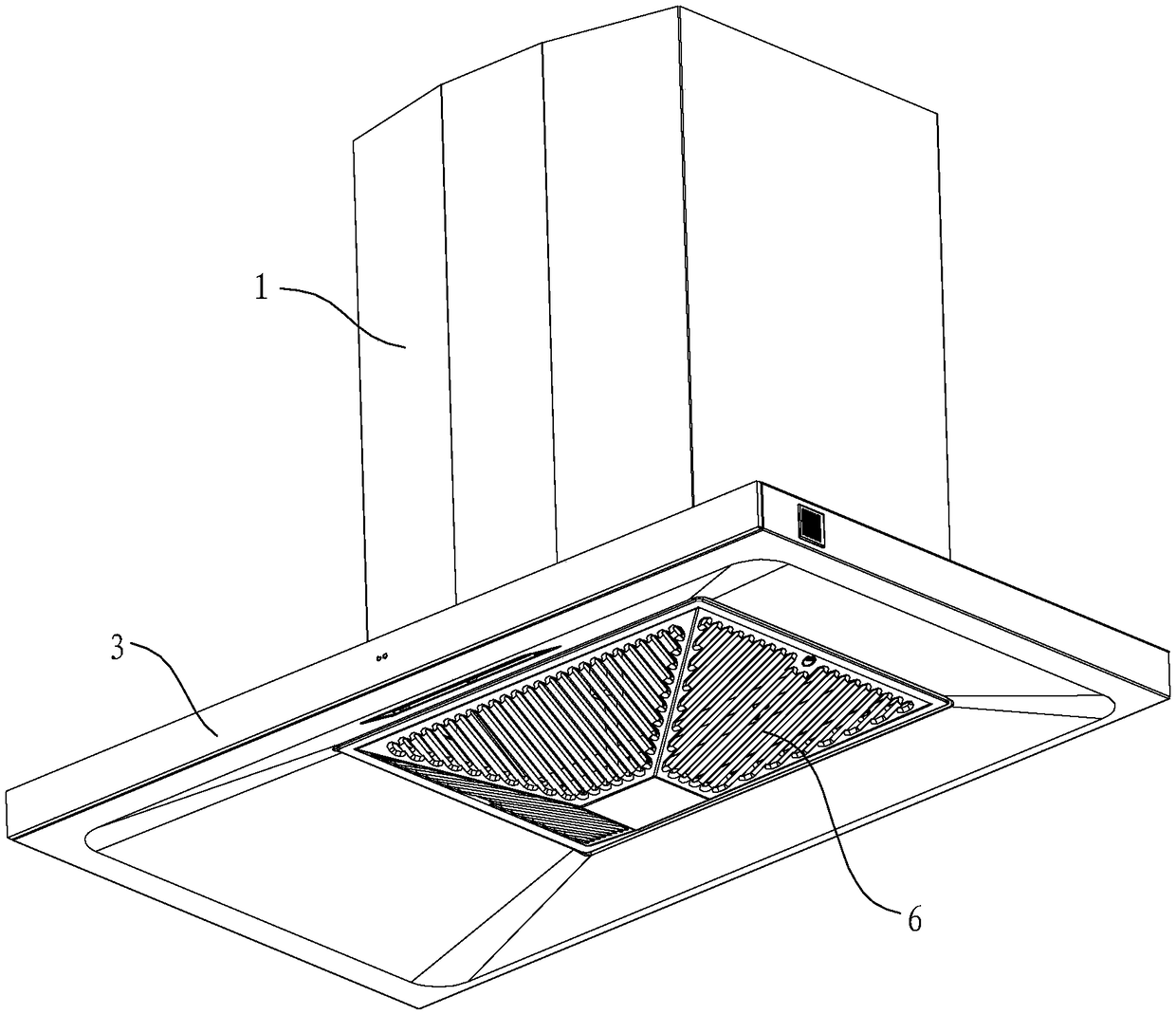

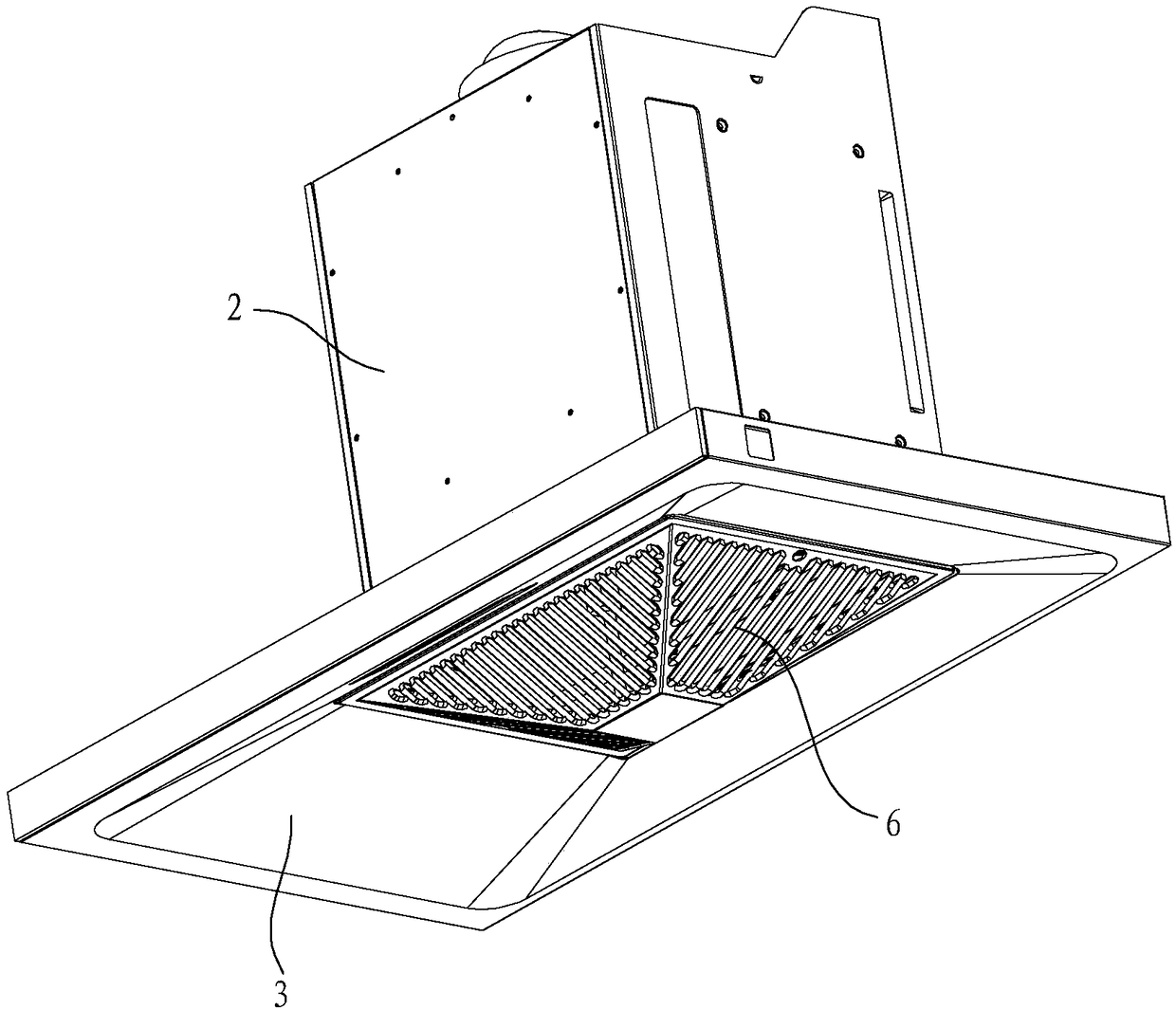

[0033] Such as Figure 1 to Figure 5 As shown, the intelligent range hood in this embodiment includes main components such as a decorative cover 1, a fan cover 2, a smoke collection cover 3, a fan 4, and an oil filter, wherein the decorative cover 1 and the fan cover 2 constitute the main components of the range hood. The casing, the decorative cover 1 is set outside the fan cover 2, the smoke collecting cover 3 is set under the fan cover 2, the fan 4 is set inside the fan cover 2 and is driven by the fan motor, and the oil filter is set at the inlet of the smoke collecting hood 3. At the tuyere, the above-mentioned structure is the conventional structure of the existing range hood.

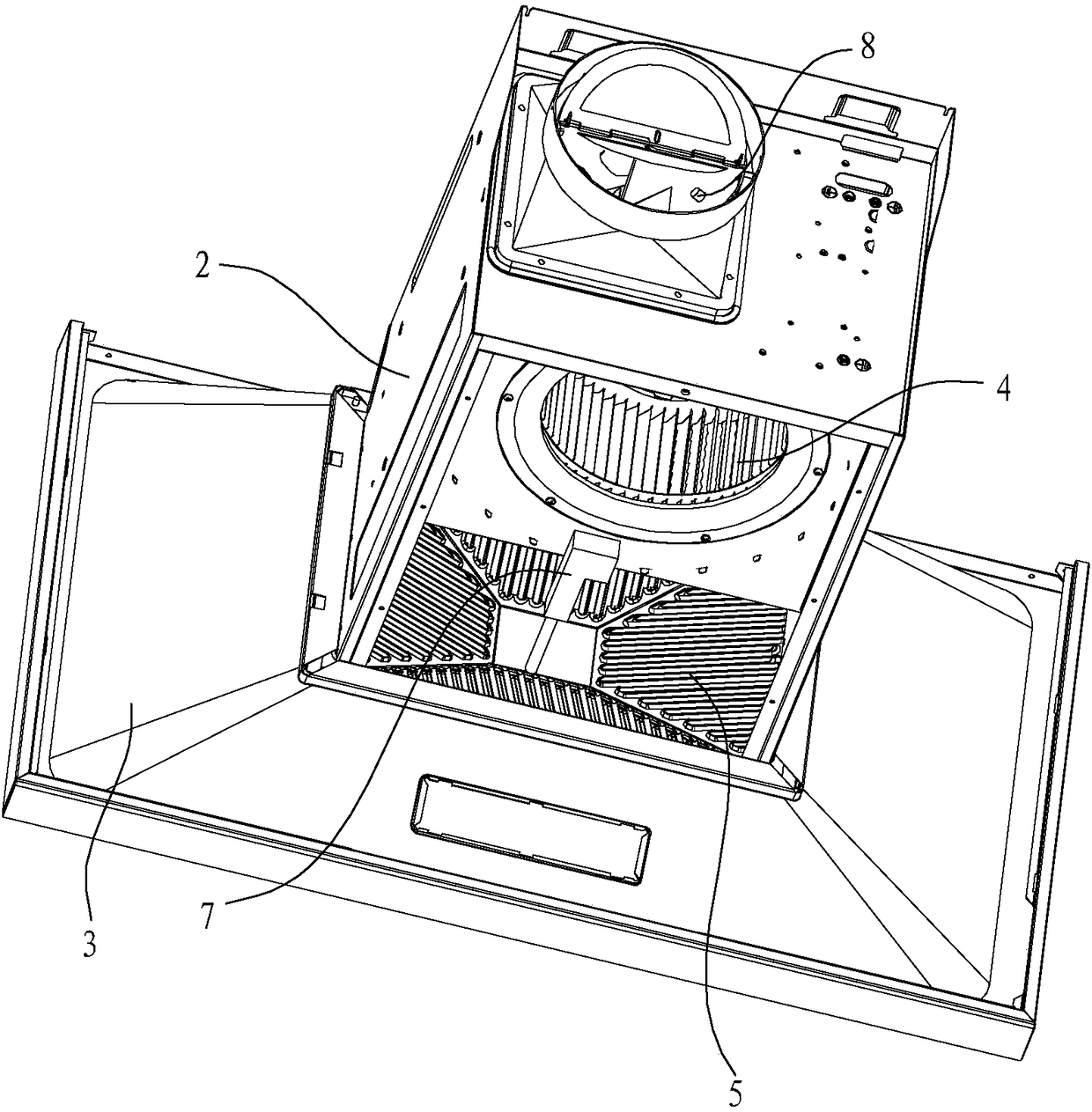

[0034] The intelligent range hood of the present embodiment also includes a controller (not shown in the figure), a push rod mechanism 7 and a pressure sensor 8, the signal output end of the pressure sensor 8 is connected with the signal input end of the controller, and the controller The rotati...

Embodiment 2

[0047] Such as Figure 7 to Figure 10 As shown, the range hood of this embodiment forms an installation cavity 9 between the decorative cover 1 and the fan cover 2 , and the push rod mechanism 7 is installed in the installation cavity 9 . The inner oil filter 5 is a fixed oil filter, the outer oil filter 6 is a movable oil filter, the inner oil filter 5 is fixed on the smoke collecting hood 3, and the drive output end of the push rod mechanism 7 protrudes downwards In the installation cavity 9 and connected to the outer oil filter 6, the outer oil filter 6 moves up and down relative to the inner oil filter 5 under the drive of the push rod mechanism 7, thereby changing the inner layer oil filter 5 and the outer oil filter. The spacing between layers of oil filter screen 6. In this embodiment, the drive output end of the push rod mechanism 7 includes two lifting rods 71 located on the left and right sides of the fan housing 2, and the lower ends of the lifting rods 71 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com