Range hood with smoke deflectors and control method thereof

A range hood and control method technology, applied in the direction of oil fume removal, heating method, household heating, etc., can solve the problems of large energy loss, long distance, escape of oil fume gas, etc., and achieve the effect of strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

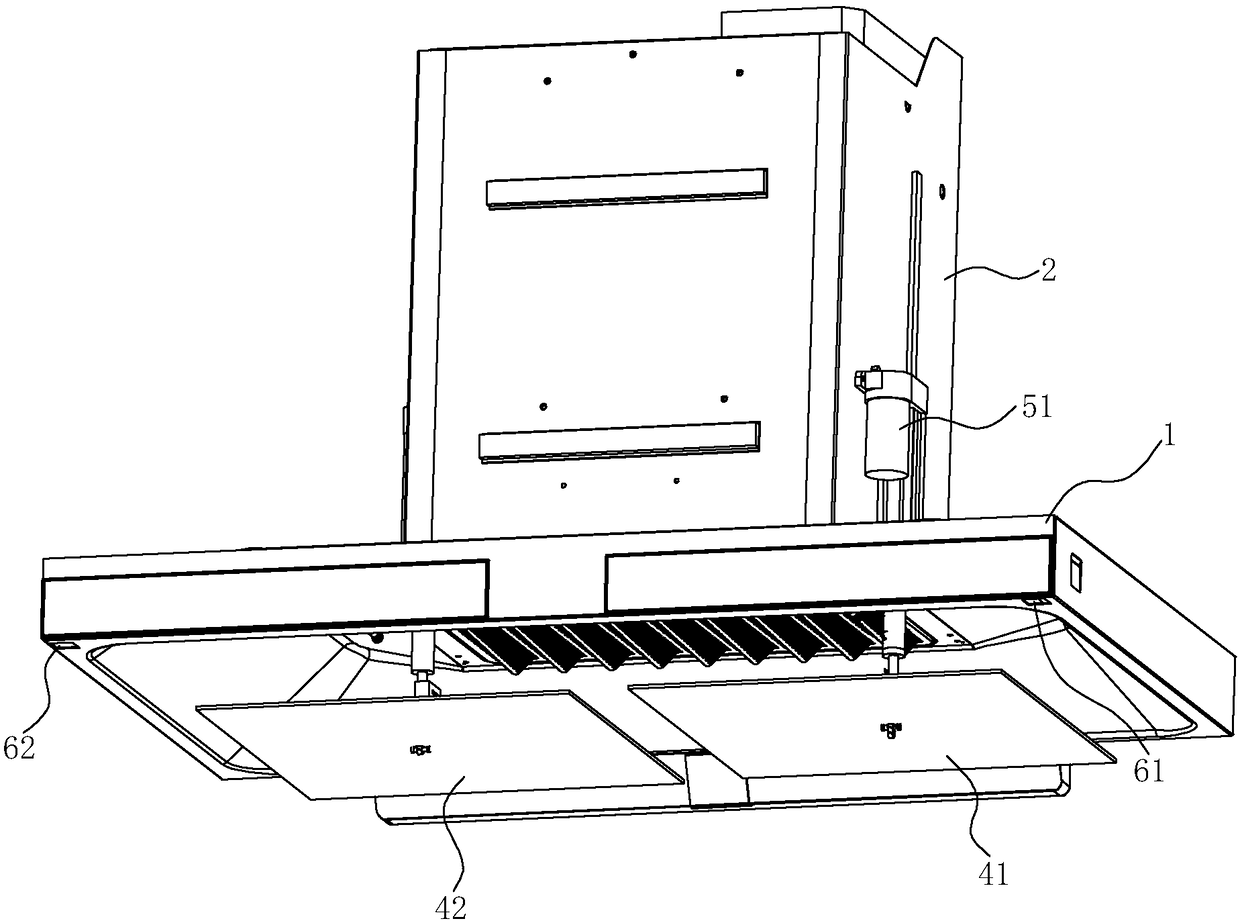

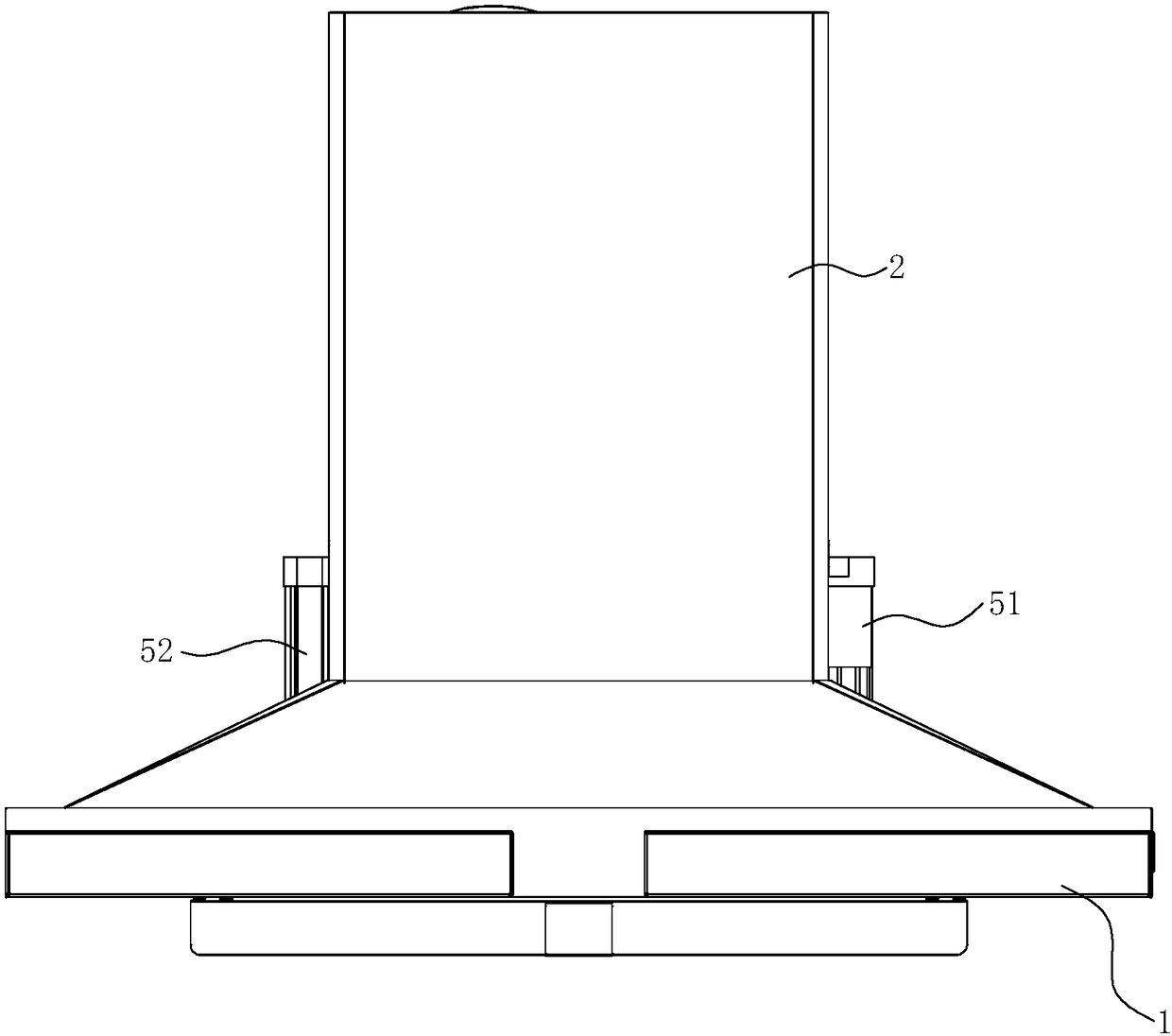

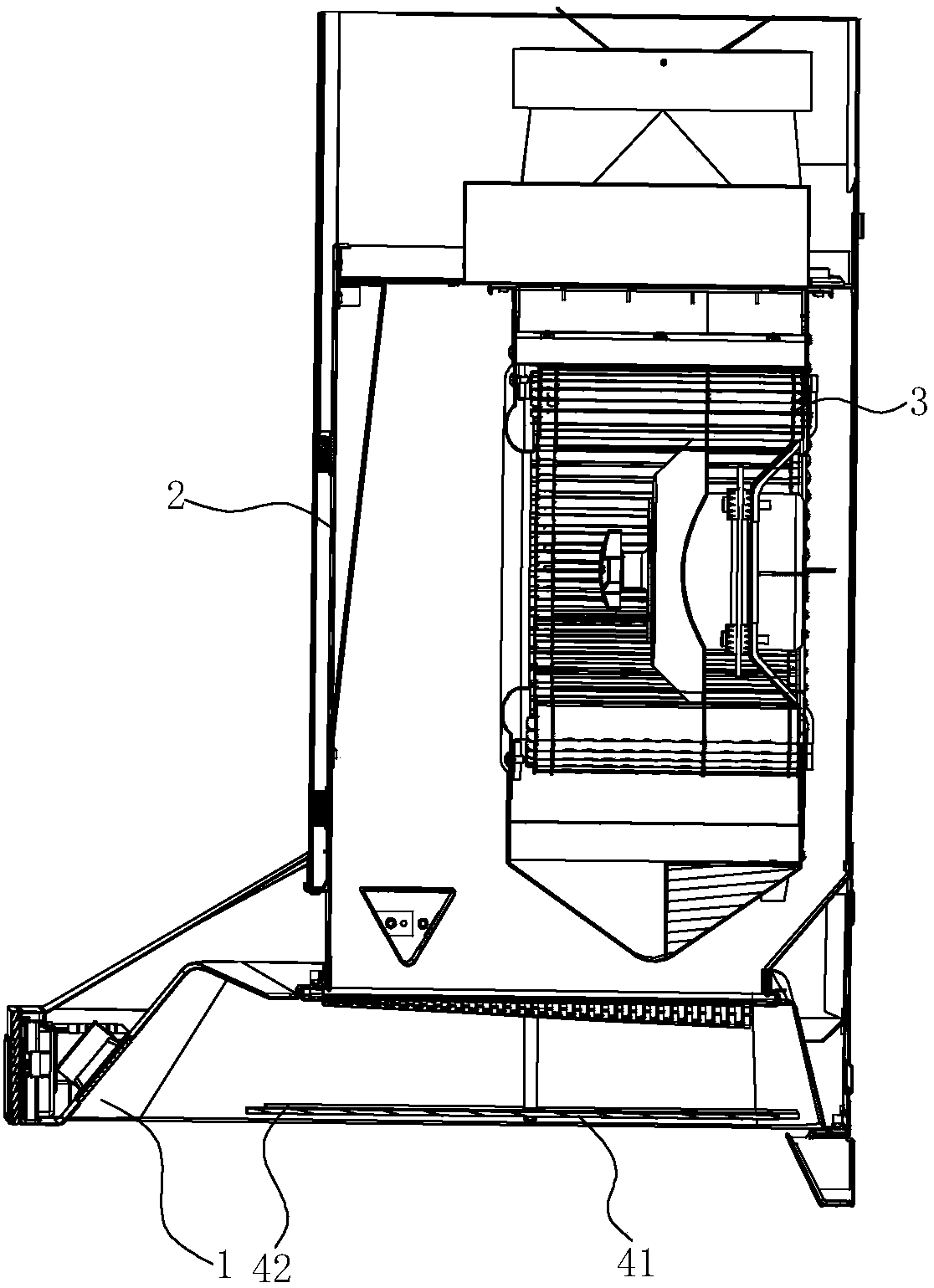

[0032] see Figure 1 ~ Figure 3 , a range hood with a smoke deflector, comprising a smoke collection hood 1, a fan cover 2 arranged above the smoke collection hood 1, and a fan 3 is arranged in the fan cover 2.

[0033] An air inlet 11 is provided on the smoke collecting hood 1, and a smoke guide plate is arranged below the air inlet 11. In this embodiment, the smoke guide plate includes a first smoke guide plate 41 and a second smoke guide plate 42, two smoke guide plates They are respectively arranged on both sides below the air inlet 11, so as to be compatible with a stove with double burners. The first smoke guide plate 41 is provided with a first driving mechanism 51, and the second smoke guide plate 42 is provided with a second drive mechanism 52, so that the first smoke guide plate 41 and the second smoke guide plate 42 can be independently driven up and down. . In this embodiment, both the first drive mechanism 51 and the second drive mechanism 52 are electric push r...

Embodiment 2

[0043] see Figure 8 and Figure 9 , the difference from the first embodiment above is that in this embodiment, the drive mechanism including the first drive mechanism 51 and the second drive mechanism 52 is used to drive the first smoke guide plate 41 and the second smoke guide plate 42 respectively. rotate.

[0044] The first driving mechanism 51 includes a first motor 511 and a first rotating shaft 512, the first motor 511 is arranged on the rear side of the smoke collecting hood 1, one end of the first rotating shaft 512 is connected with the output shaft of the first motor 511, and the other end rotates The first smoke guide plate 41 is connected to the first rotating shaft 512, and can be fixed by welding, for example. Correspondingly, the second drive mechanism 52 includes a second motor 521 and a second rotating shaft 522, the second motor 521 is arranged on the rear side of the smoke collecting hood 1, one end of the second rotating shaft 522 is connected with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com