Prepreg viscosity quantitative measuring method

A test method and prepreg technology, applied in the field of testing to achieve the effect of improving the use process and improving process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

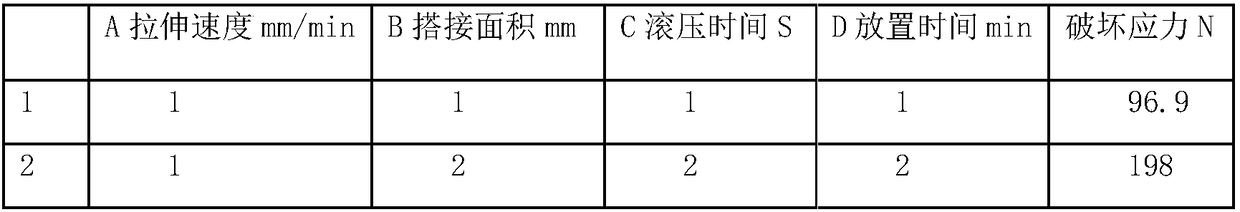

[0053] Quantitative viscosity test of 3238A / CF3052 medium temperature curing epoxy prepreg

[0054] 1. Test preparation

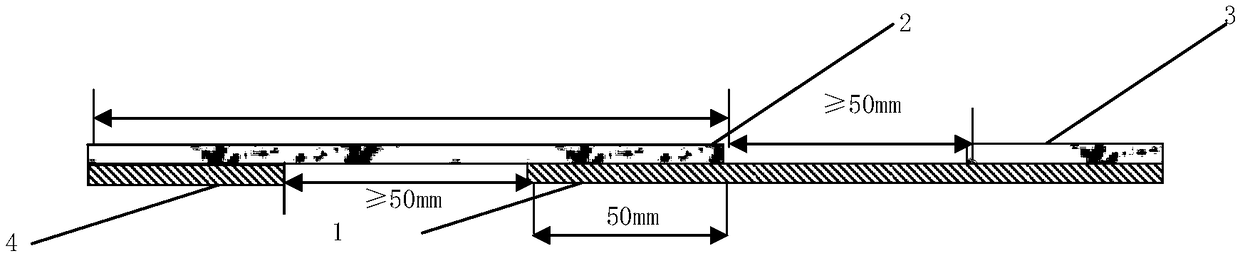

[0055] Take out the product 3238A / CF3052 medium temperature curing epoxy prepreg from the cold storage, and open the package after placing it at room temperature for at least 6 hours. Cut the prepreg sample, the size of the sample is 160mm×25mm, the width of the sample is accurate to ±0.1mm, and the length of the bonding surface is 50mm±0.5mm. The number of samples taken along the longitudinal direction of the sample is 5. Prepare a stainless steel plate (roughness Ra<1.6um), the size of the stainless steel is 160mm×25mm, and the quantity is 5 pieces.

[0056] 2. Test conditions (environment)

[0057] The sample needs to be adjusted and tested under the condition that the ambient temperature reaches 23°C±2°C and the relative humidity is not greater than 65%.

[0058] 3. Test procedure (test steps)

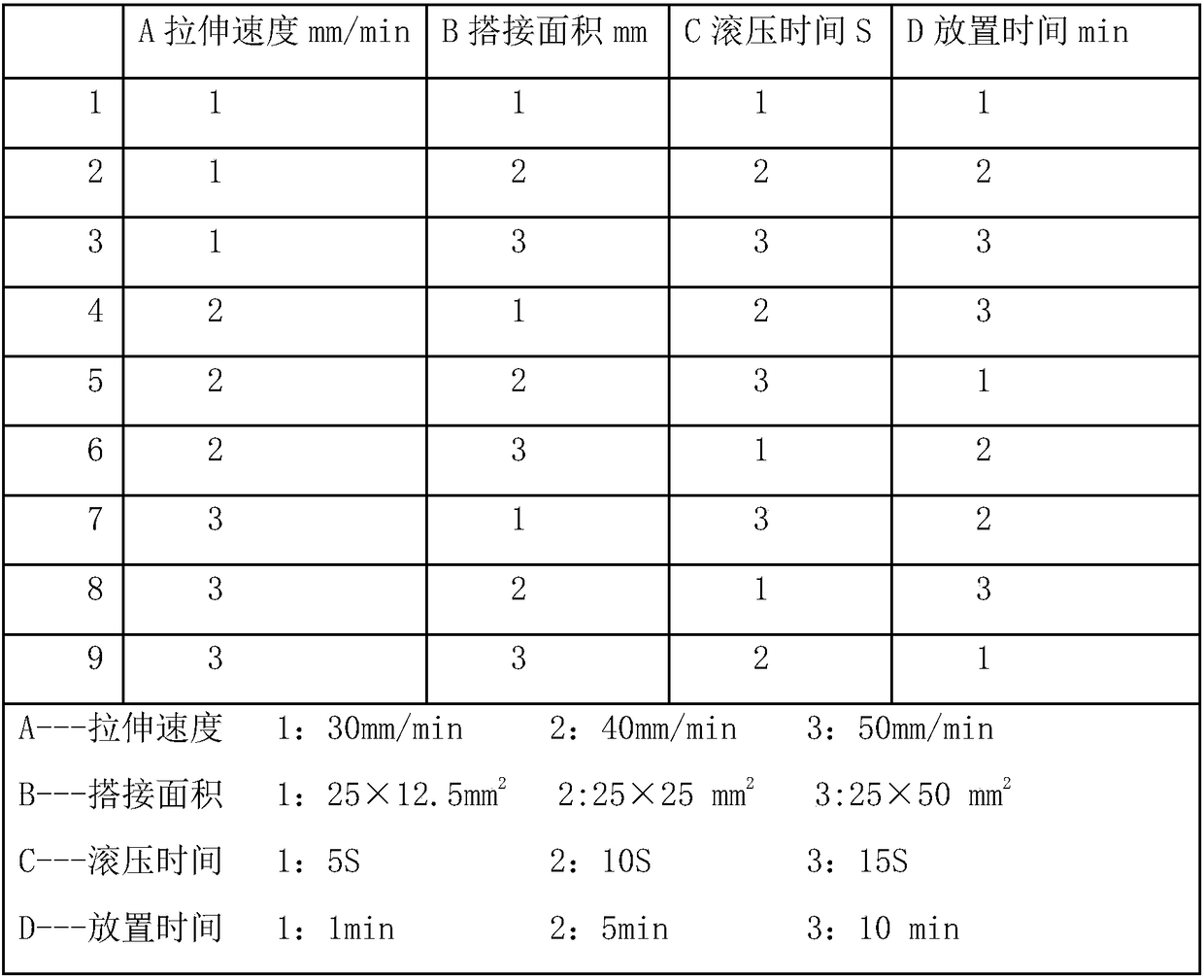

[0059] Before the test, lap the cut single-layer prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com