Process for preparing low-viscosity and high-temperature-resistance protective film

A technology of high temperature resistant protective film and preparation process, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc. , Easy to tear off, good fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation process for a low-viscosity high-temperature-resistant protective film, specifically comprising the following steps:

[0025] S1. PET film pretreatment: Corona treatment is performed on the PET film, and then washed with acetone and alcohol in sequence, and then the film is dried in a vacuum oven at 70°C for 12 hours, and set aside;

[0026] S2, preparing glue, the steps are as follows:

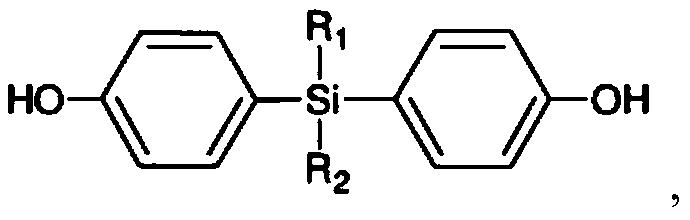

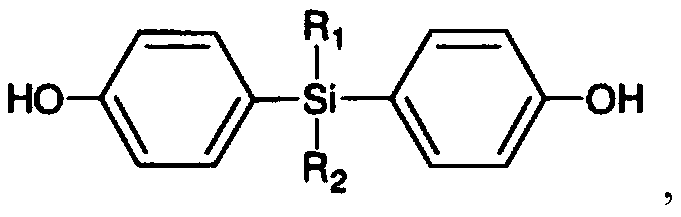

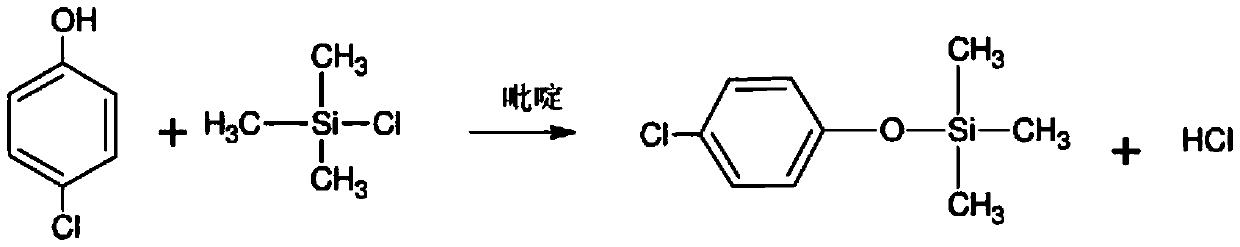

[0027] S21. Preparation of silicon-containing diphenol, specific steps: (1) Add 0.11mol of p-chlorophenol, 0.2mol of pyridine, and 100mL of anhydrous toluene into the reaction flask, add 0.12mol of trimethylchlorosilane dropwise under stirring in an ice bath, and drop After the addition, the temperature was raised to room temperature, stirred and reacted for 8 hours, the filtered solution was evaporated and concentrated and dried in vacuo to obtain a liquid intermediate product a; (2) Add 0.2 mol of sodium metal and 100 mL of anhydrous toluene into a three-necked flask, e...

Embodiment 2

[0032] A preparation process for a low-viscosity high-temperature-resistant protective film, specifically comprising the following steps:

[0033] S1. PET film pretreatment: Corona treatment was performed on the PET film, and then washed with acetone and alcohol in sequence, and then the film was dried in a vacuum oven at 70°C for 12 hours, and then set aside.

[0034] S2, preparing glue, the steps are as follows:

[0035] S21. Preparation of silicon-containing diphenol, specific steps: (1) Add 0.11mol of p-chlorophenol, 0.2mol of pyridine, and 100mL of anhydrous toluene into the reaction flask, add 0.12mol of trimethylchlorosilane dropwise under stirring in an ice bath, and drop After the addition, the temperature was raised to room temperature, stirred and reacted for 8 hours, the filtered solution was evaporated and concentrated and dried in vacuo to obtain a liquid intermediate product a; (2) Add 0.2 mol of sodium metal and 100 mL of anhydrous toluene into a three-necked f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com