Multi-color-temperature COB (chip on board) light source and encapsulating method thereof

A packaging method and multi-color temperature technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as jumper collapse, external force applied by jumper, and influence on the yield of COB light sources, etc., to achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

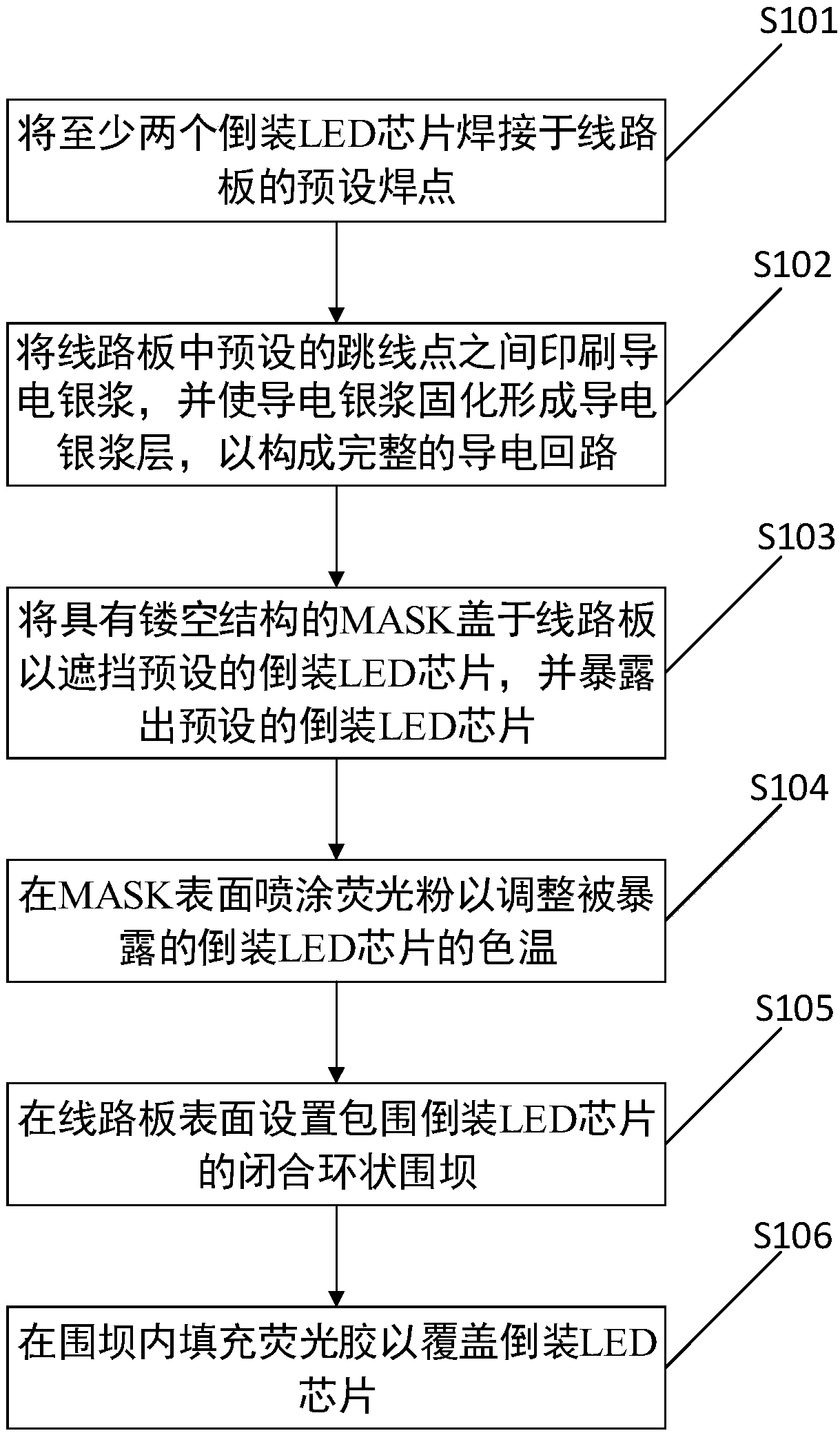

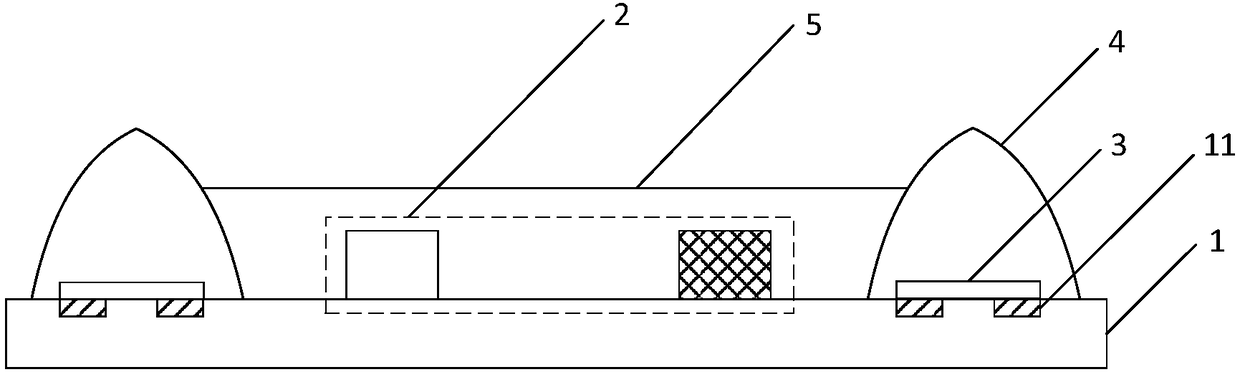

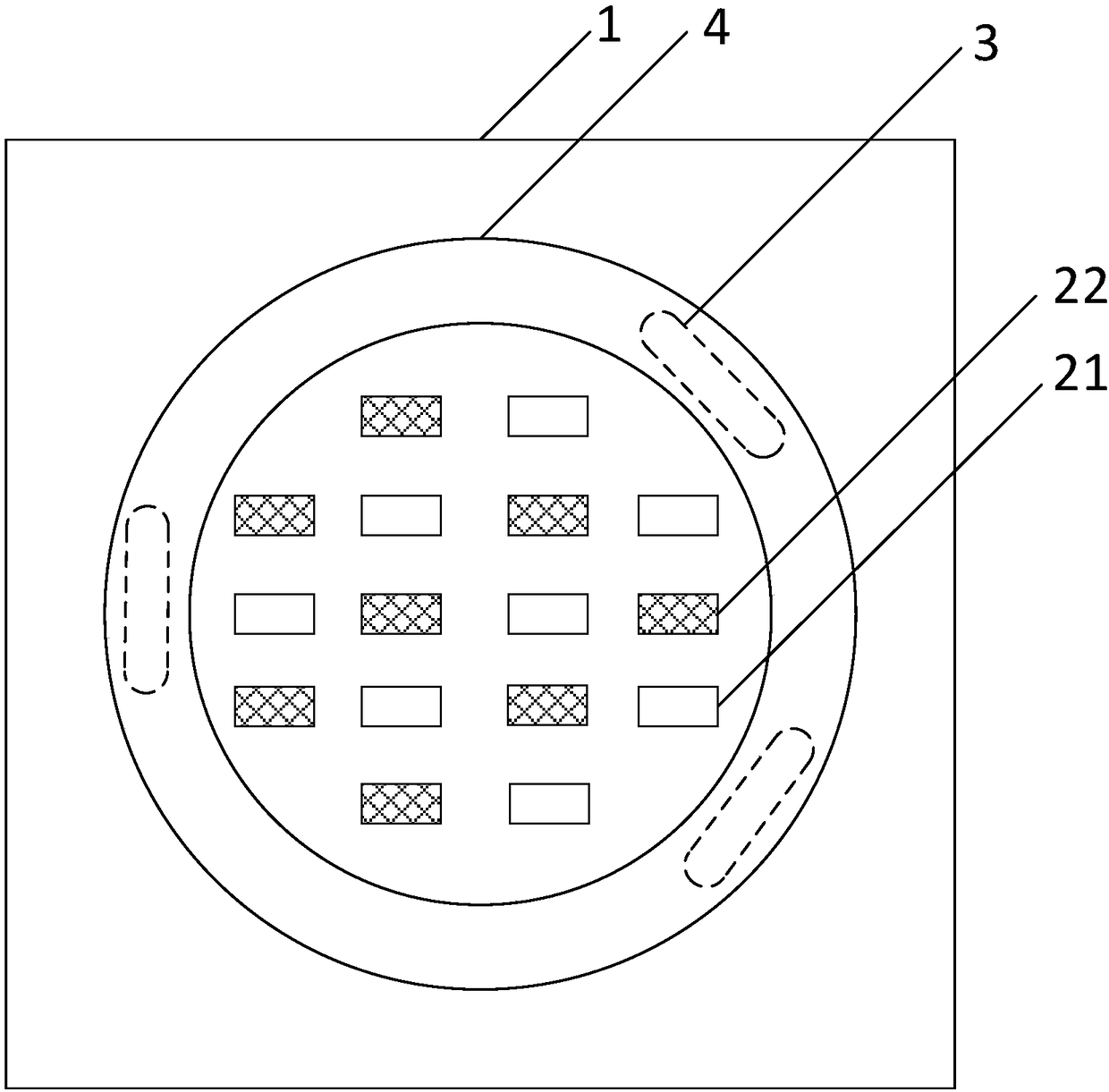

[0041] The core of the invention is to provide a multi-color temperature COB light source. In the prior art, in the multi-color temperature COB light source, different conductive circuits are required for different color temperatures to control the LED chips with different color temperatures separately, which makes the circuit in the circuit board very complicated, and the circuit crossing often occurs. Condition. When the lines cross, it is usually necessary to expose two jumper points at the two ends of the cross in one of the lines, and then connect the two jumper points with gold wires by "bridge" to form a complete electrical circuit. Sometimes the jumper wire needs to be suspended on the circuit board. However, the jumper is very fragile, and it is easy to exert external force on the jumper during the production and transportation of the COB light source, causing the jumper to collapse and break, which will directly affect the yield rate of the COB light source and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com