Fruit washing and drying equipment

A technology for drying equipment and fruits, which is applied in the direction of solid separation, sieves, grills, etc., which can solve the problems of unreachable fruit cleaning, discontinuous working process, and large labor consumption, so as to save energy, improve efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

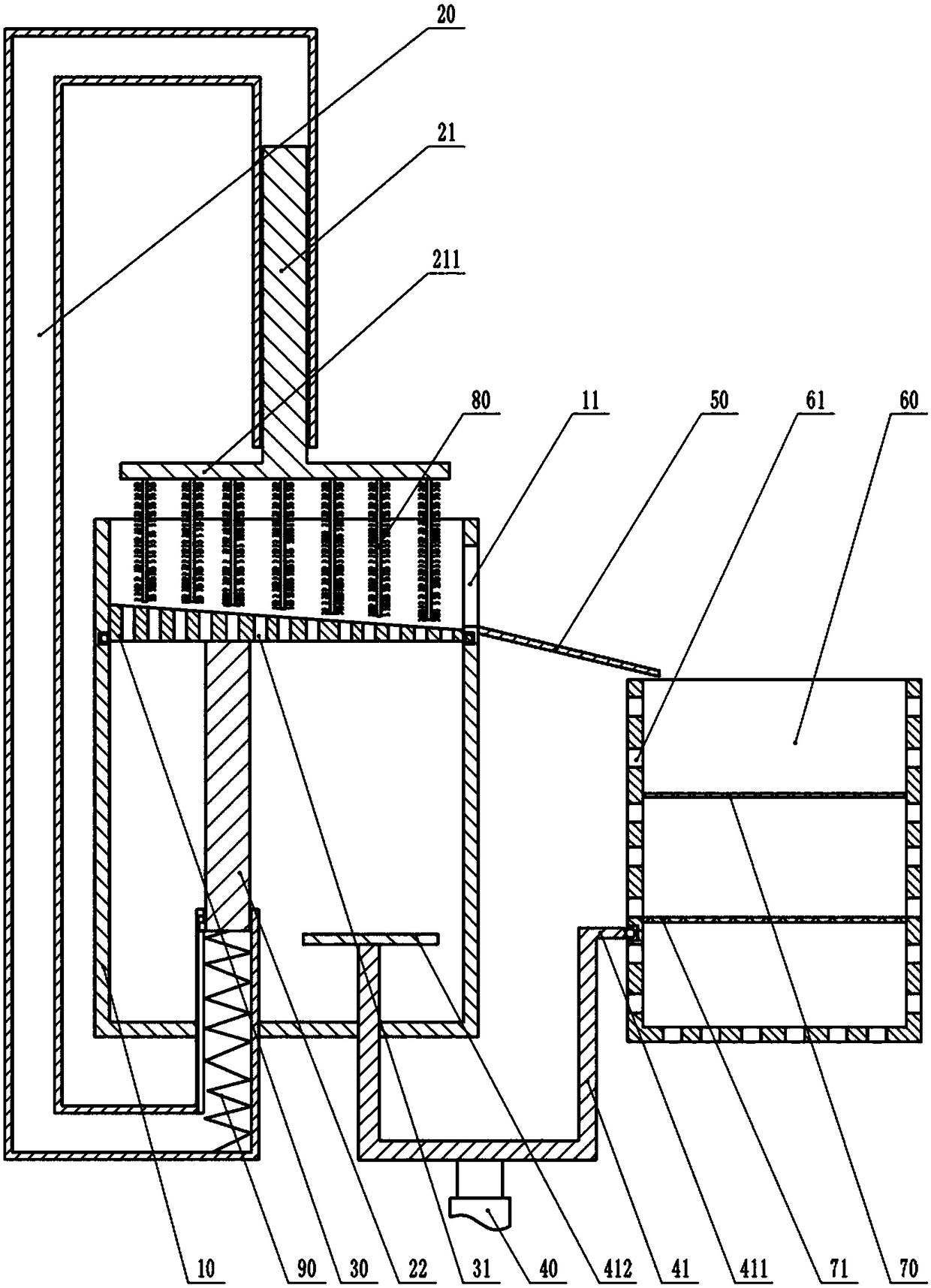

[0021] Instructions attached figure 1 The reference signs in include: cleaning cylinder 10, discharge port 11, connecting column 20, upper plunger 21, mounting plate 211, lower plunger 22, supporting plate 30, water hole 31, hydraulic cylinder 40, push rod 41 , Crossbar 411, support plate 412, feeding plate 50, drying cylinder 60, through hole 61, primary screen 70, secondary screen 71, brush bar 80, spring 90.

[0022] like figure 1As shown, the fruit washing and drying equipment includes a frame, a cleaning unit, a drying unit and a power unit. The cleaning unit includes a cleaning cylinder 10 and a connecting column 20 with a C-shaped longitudinal section. The connecting column 20 is filled with hydraulic oil; the cleaning cylinder 10 is fixed Connected on the frame, the connecting column 20 is located on the left side of the cleaning cylinder 10 . The inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com