Tunnel construction machine for ground depression prevention

A tunnel construction and ground surface technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of small labor, heavy labor, and easy drop of bolts, and achieve the effect of simple bolt installation and small labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

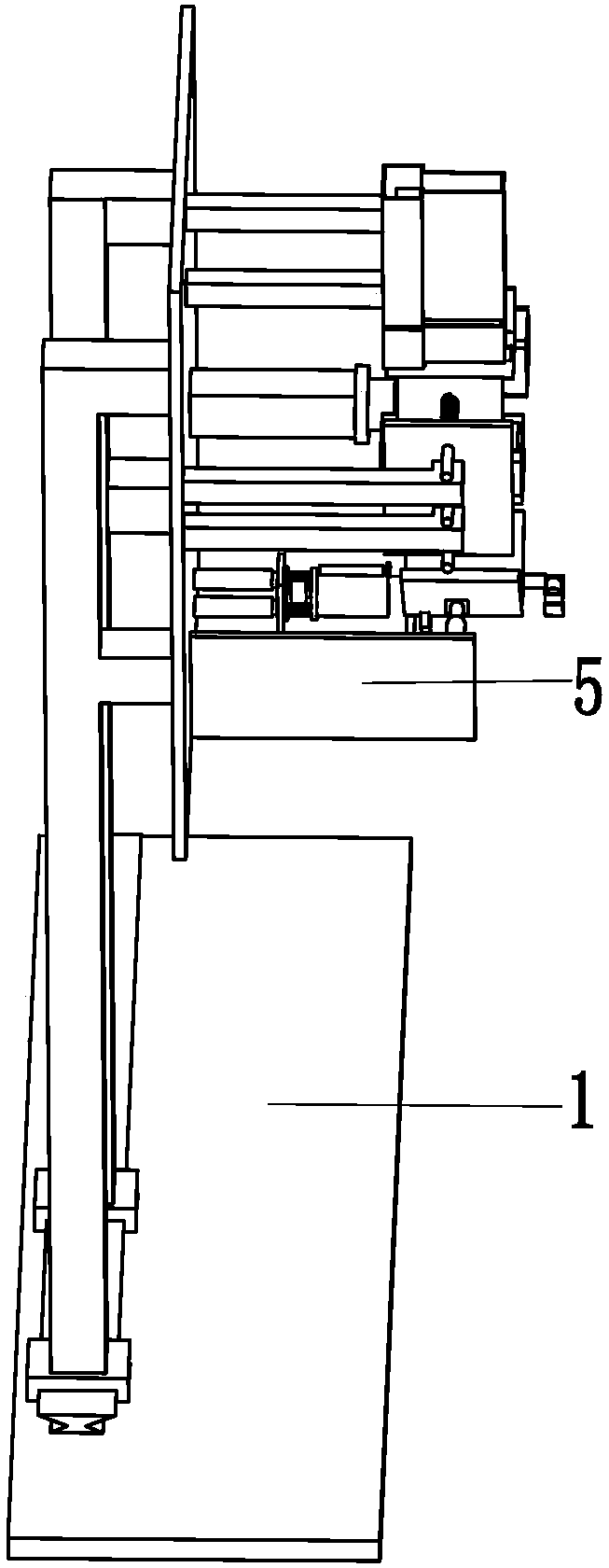

[0024] Such as Figure 1 to Figure 5 As shown, a tunnel construction machine for preventing ground subsidence includes a supporting base plate 1 and a blanking device 5, and a blanking device 5 is installed on the top of the supporting base plate 1.

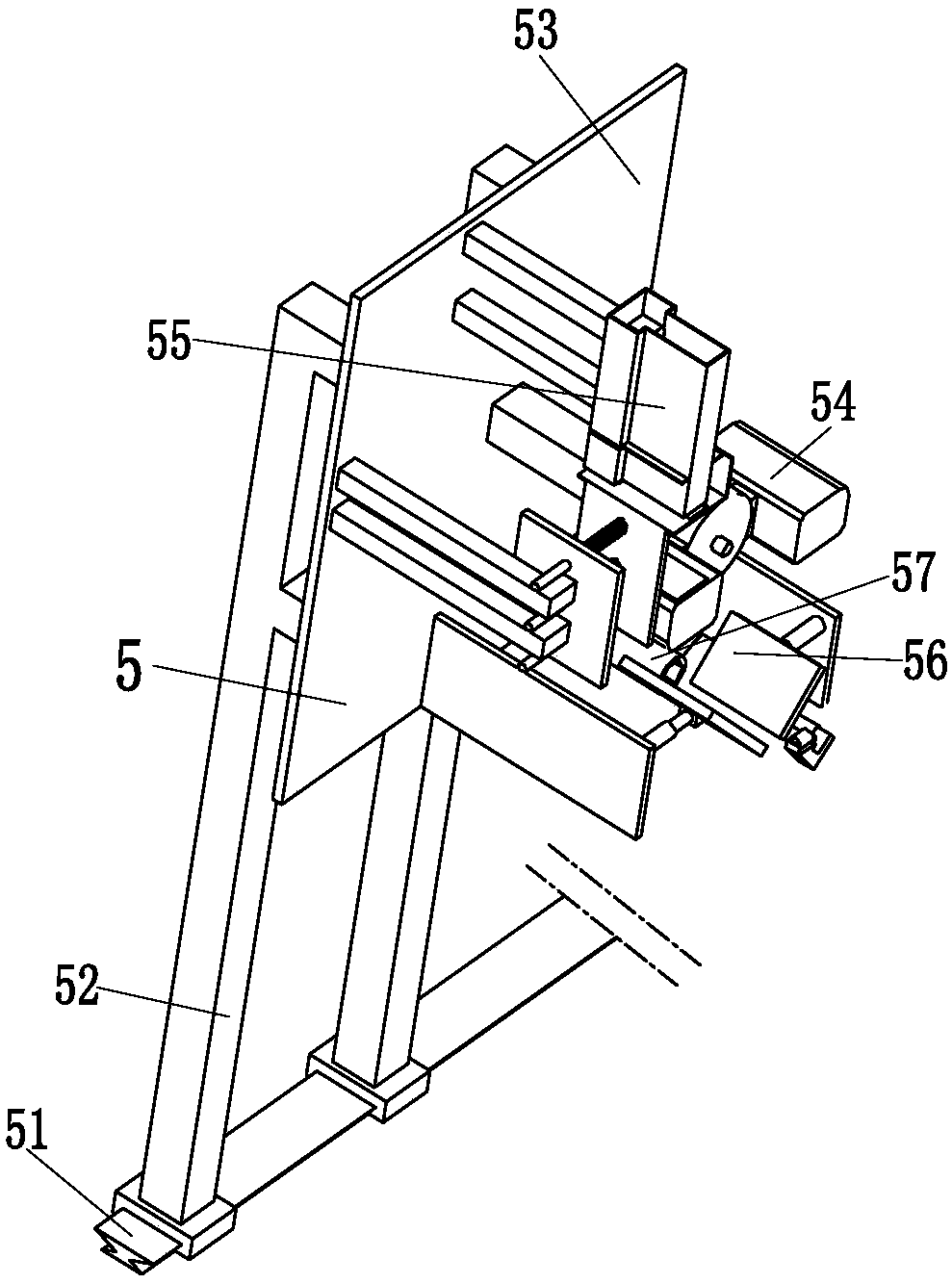

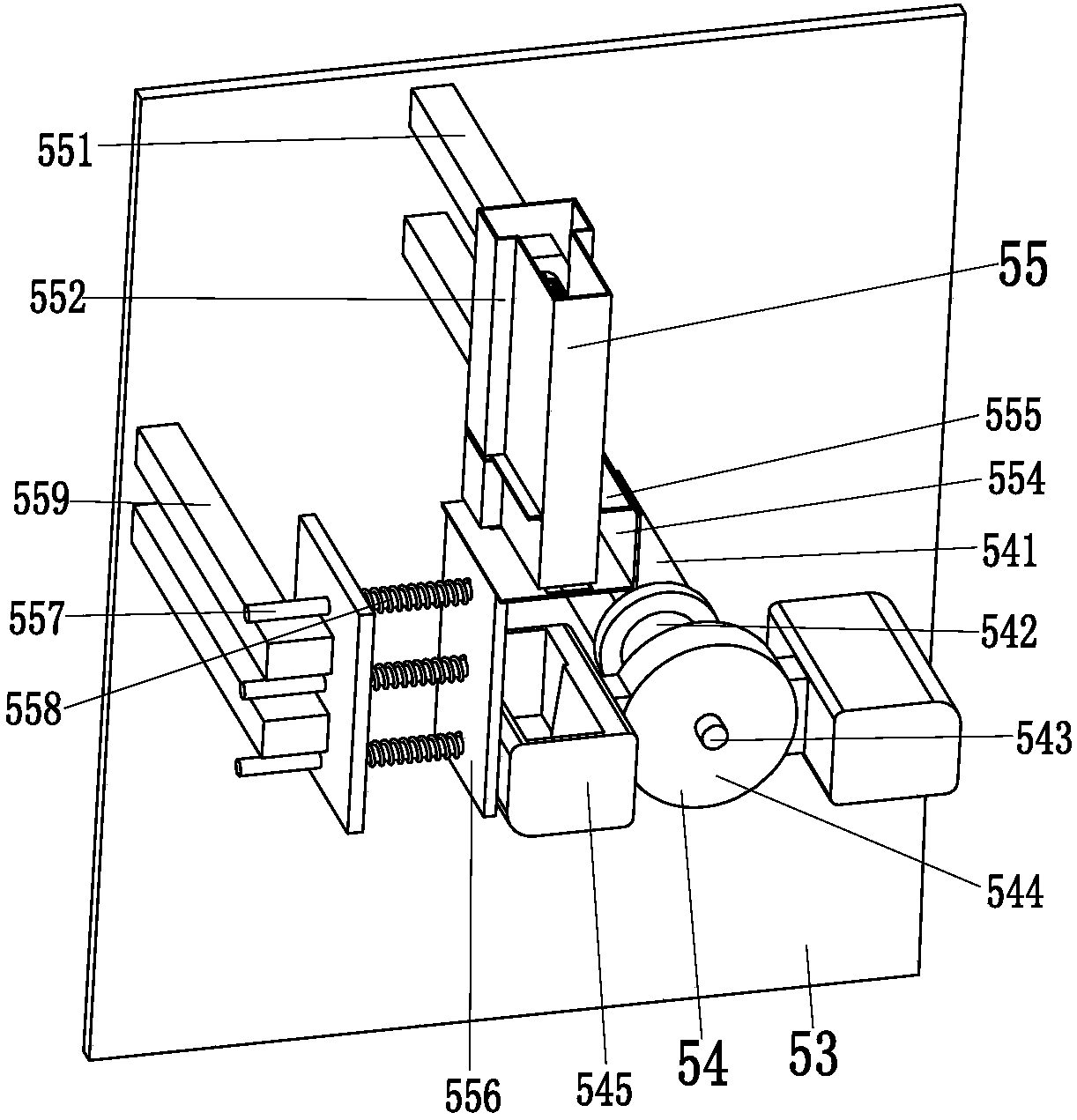

[0025] The blanking device 5 includes a blanking electric slider 51, a blanking connecting column 52, a blanking support plate 53, a conveying mechanism 54, a blanking mechanism 55, a returning mechanism 56 and a rotating mechanism 57, and a blanking electric sliding block. 51 is installed on the top of the gusset support plate 48, the blanking suppo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap