Fabricated integrated bathroom

A toilet and prefabricated technology, applied in the field of toilets and prefabricated toilets, can solve problems such as water seals are easy to dry up, falling boards take up building space, and the overall toilet is not solid and hollow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

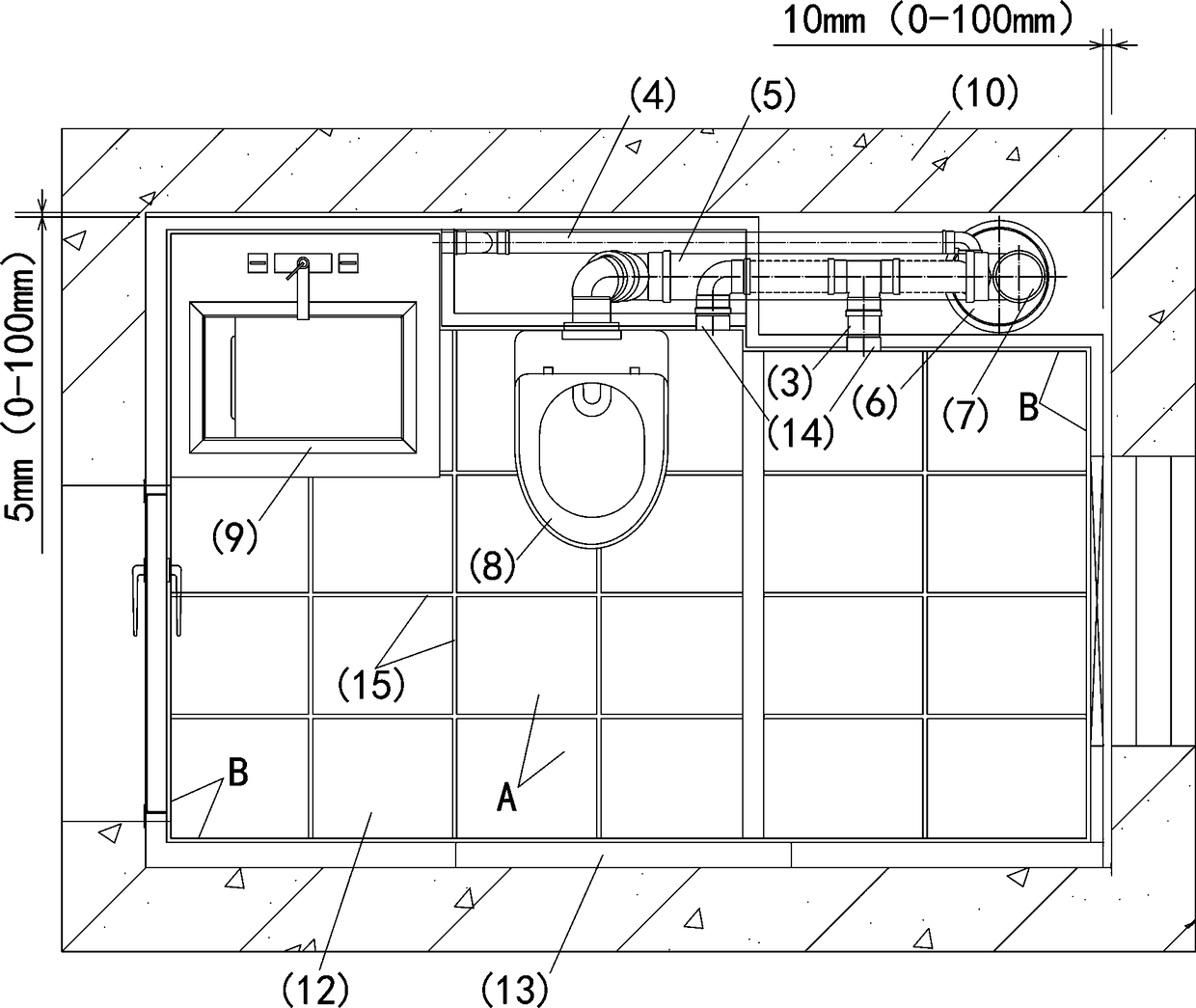

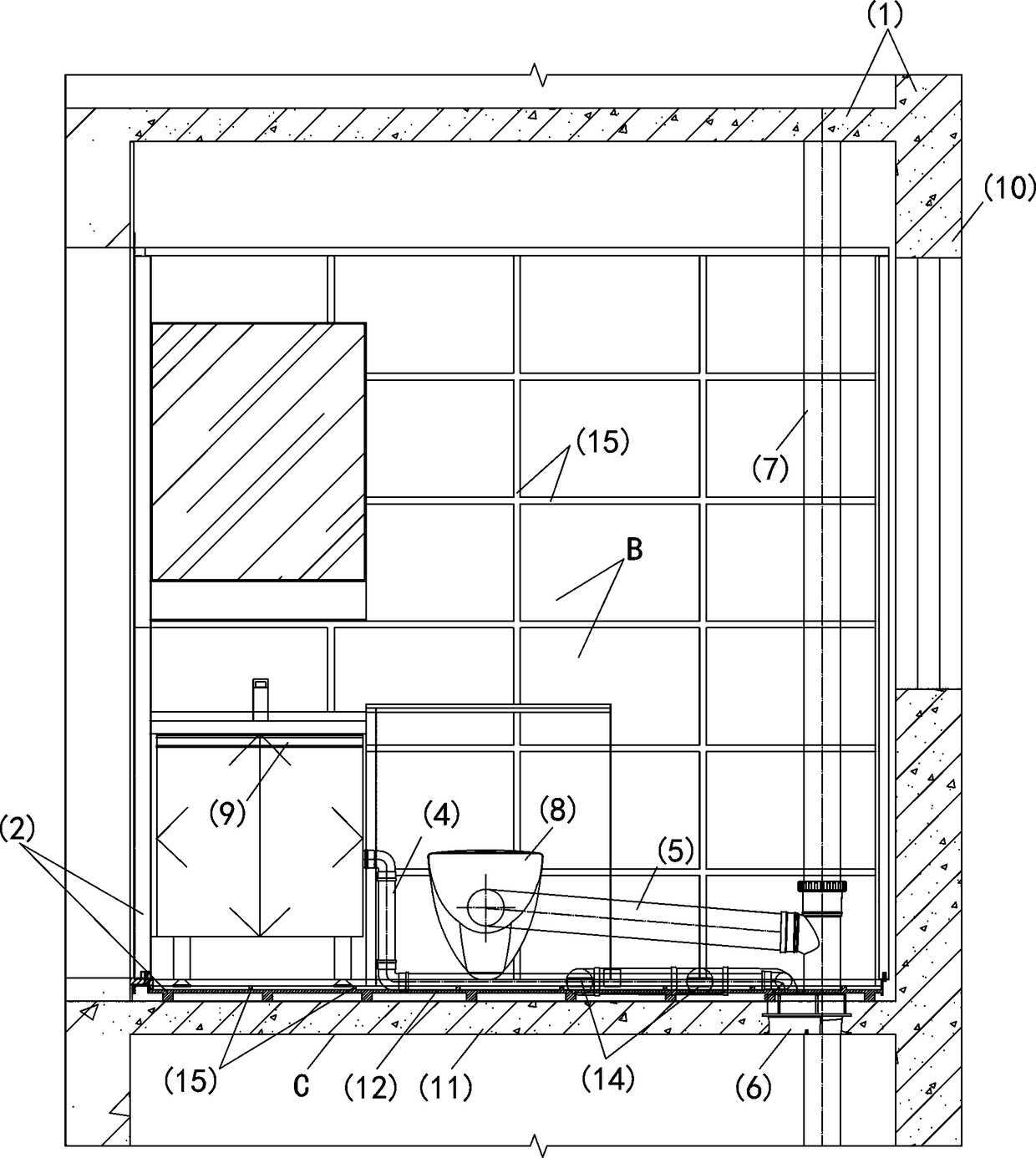

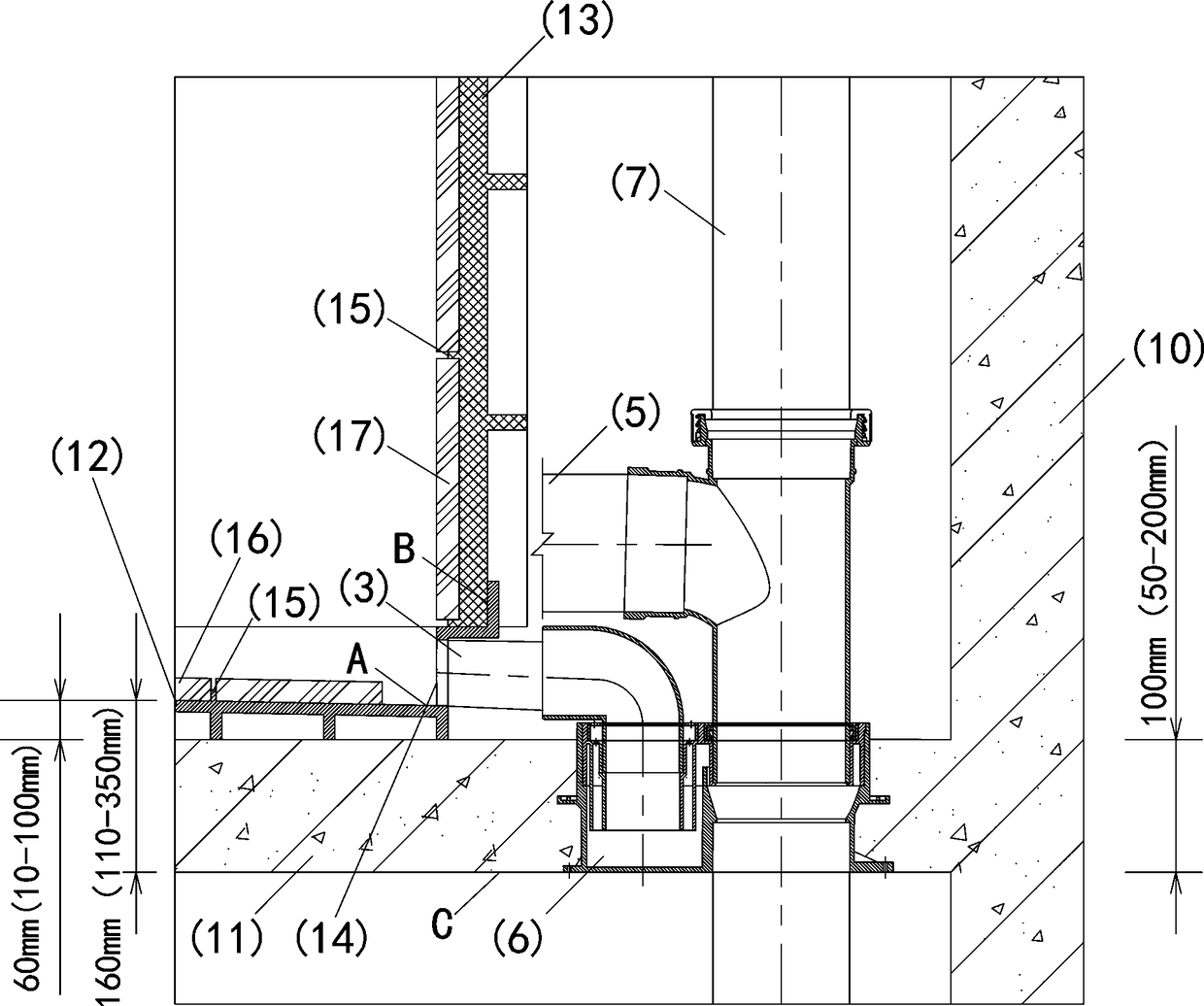

[0014] like figure 1 , 2 . As shown in 3, in the prefabricated integrated toilet according to the present invention, the tray (12) is an integral component, and there is no hole penetrating the tray (12) on the transverse plane A, and on the facade B where the transverse plane A and the facade B intersect There are 2 floor drain holes (14) penetrating the facade B, and the hoarding (13) is composed of multiple separable plates with a width of 600mm and a height of 2200mm, standing on the facade B of the tray (12); the waste water The branch pipe (4) penetrates the coaming (13), connects to the washbasin (9) inside, and connects to the integrated water seal (6) outside, and the floor drain pipe (3) has a ground drain hole (14) at one end and an integrated water seal (6) at the other end; The branch pipe (5) penetrates the coaming (13), connects to the toilet (8) inside, and connects to the drainage standpipe (7) outside; the integrated water seal (6) is connected to the draina...

Embodiment 2

[0016] like figure 1 , 2 , 4, in the prefabricated integrated toilet of the present invention, the tray (12) is an integral component, there is no hole penetrating the tray (12) on the transverse plane A, and on the facade B where the transverse plane A and the facade B intersect There are 2 floor drain holes (14) penetrating the facade B, and the hoarding (13) is composed of multiple separable plates with a width of 600mm and a height of 2200mm, standing on the facade B of the tray (12); the waste water The branch pipe (4) penetrates the coaming (13), connects to the washbasin (9) inside, and connects to the integrated water seal (6) outside, and the floor drain pipe (3) has a ground drain hole (14) at one end and an integrated water seal (6) at the other end; The branch pipe (5) penetrates the coaming (13), connects to the toilet (8) inside, and connects to the drainage standpipe (7) outside; the integrated water seal (6) is connected to the drainage riser (7) as an integra...

Embodiment 3

[0018] like figure 2 As shown, in the prefabricated integrated toilet of the present invention, there are limit ribs (13) protruding from the transverse surface A on the transverse surface A of the tray (12) with a thickness of 1 mm, a height of 5 mm, and an interval of 300 mm. Floor tiles (16) are paved in the grid formed by the bit ribs (15).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com