Blowout-prevention pipe column and technique in water injection well operation pipe

A technology for working pipes and internal blowout prevention, which is applied to wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve problems such as inability to control the liquid in the oil pipe, failure to re-seal the oil pipe, and difficulty in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

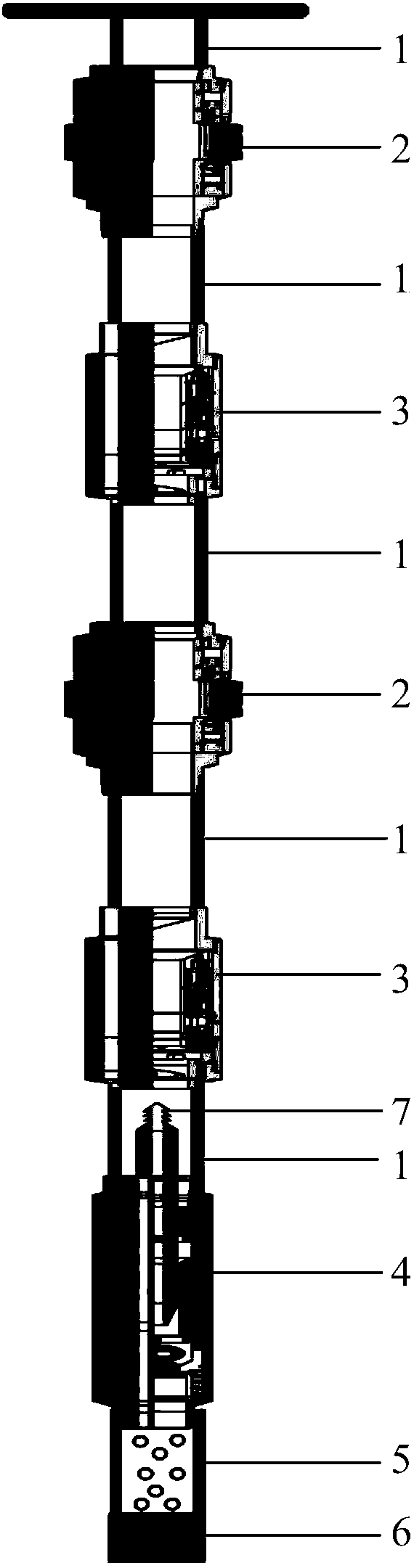

[0012] Specific embodiments: The present invention will be further described in detail below in conjunction with the accompanying drawings. The blowout preventer string in the water injection well operation pipe of the present invention is composed of oil pipe 1, washable well packer 2, anti-backflow bridge type eccentric water distributor 3, two-way anti- Spray ball seat 4, screen pipe 5, wire plug 6 and impact rod 7; among them, the washable packer 2, anti-reflux bridge type eccentric water distributor 3, two-way anti-blowout ball seat 4 pass through the thread and oil pipe 1 in turn Connection, two-way blowout preventer ball seat 4, screen pipe 5, and plug 6 are connected by screws, and the impact rod 7 is inside the two-way blowout preventer ball seat 4; the blowout prevention process in the water injection well operation pipe using the blowout preventer string in the water injection well operation pipe It is achieved through the following steps:

[0013] a. Firstly, conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com