Movable wellhead platform for offshore marginal oilfield development and usage method

A marginal oilfield and platform technology, applied in the field of movable wellhead platforms, can solve the problems of inability to meet the production needs of oilfields with different water depths, increased construction costs, poor water depth adaptability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention easier to understand, the technical solutions and technical effects of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

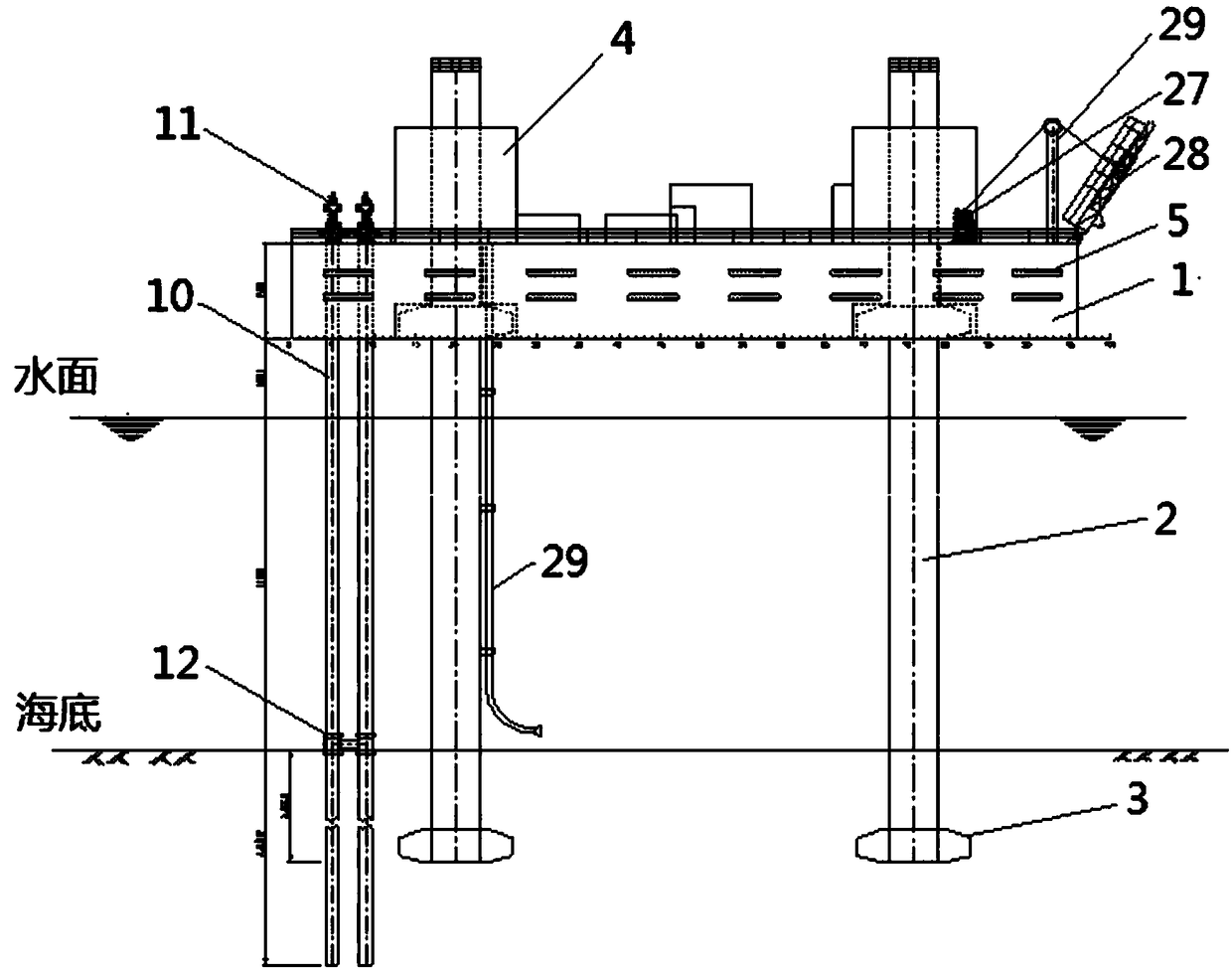

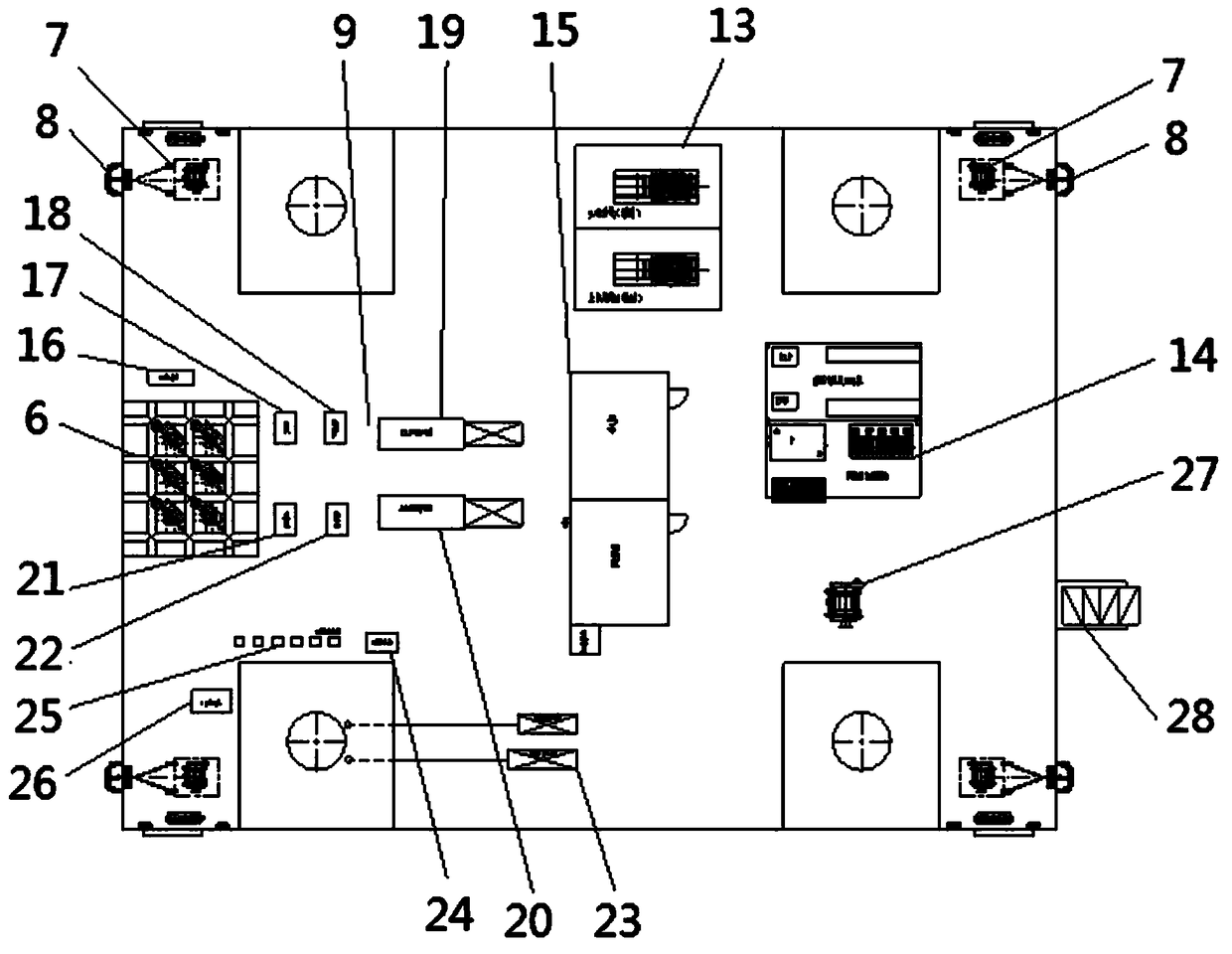

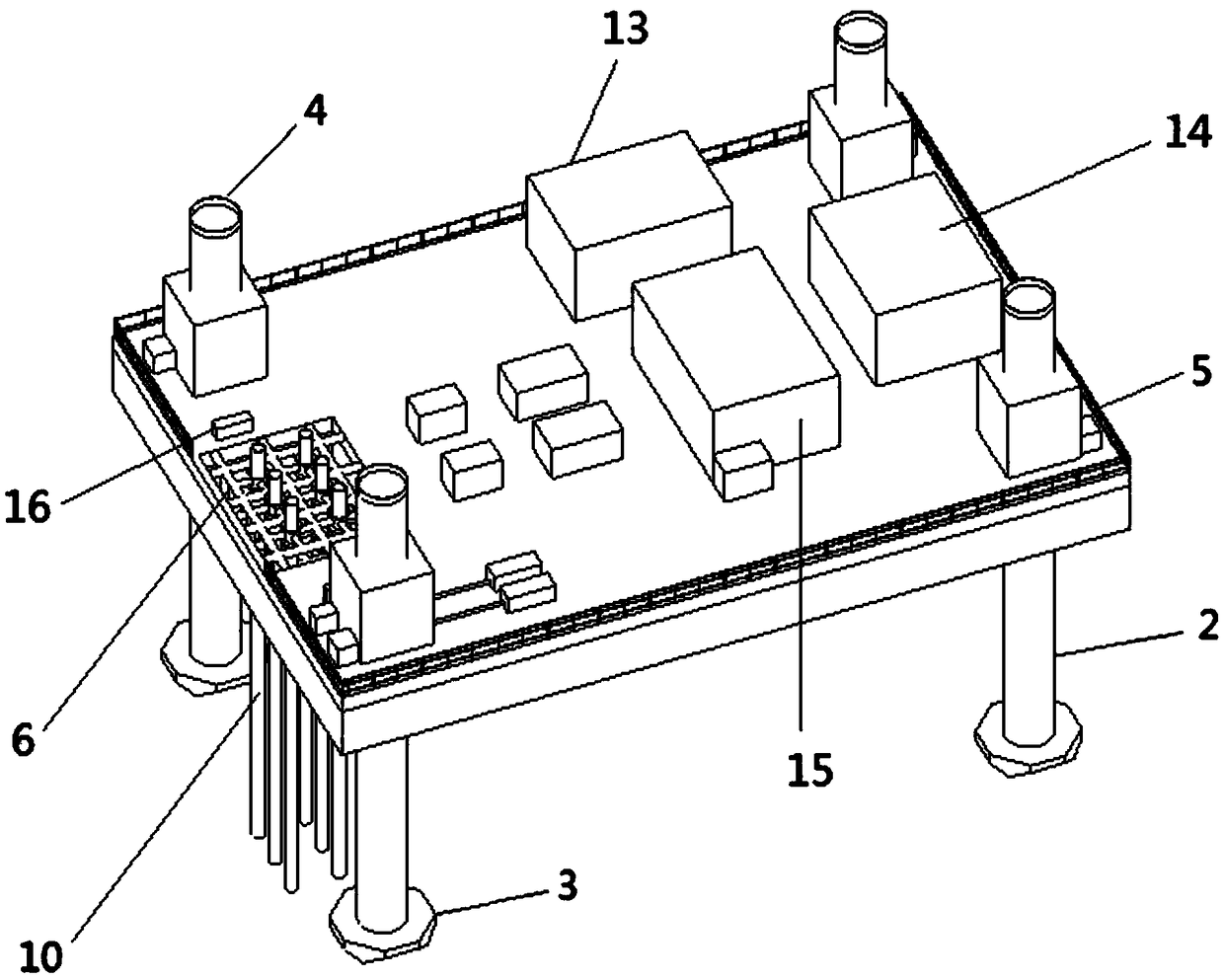

[0030] see figure 1 , figure 2 , image 3 , the mobile wellhead platform used in the development of offshore marginal oilfields according to the present invention includes a platform main body 1 with a box-shaped structure and a ballast tank, and two pile legs 2 are respectively symmetrically installed on the bow and stern of the platform main body 1 , the upper end of each of the legs 2 is respectively connected to the platform main body 1 through a hydraulic lifting device 4 installed on the platform body 1, and each of the legs 2 is provided with four rows at equal distances for lifting Positioned pin holes, along the height direction of the legs 2 are installed a subsea oil pipeline standpipe 29 for oilfield production, and fixed winche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com