Air gap special tool for checking gap between stator and rotor of compressor motor of refrigerator

A technology for refrigerator compressors and special tools, which is applied in the direction of mechanical clearance measurement, etc., can solve the problems of difficult replacement and large loss of air gap feeler gauge, and achieve the effects of improving product quality, reducing loss and saving procurement funds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

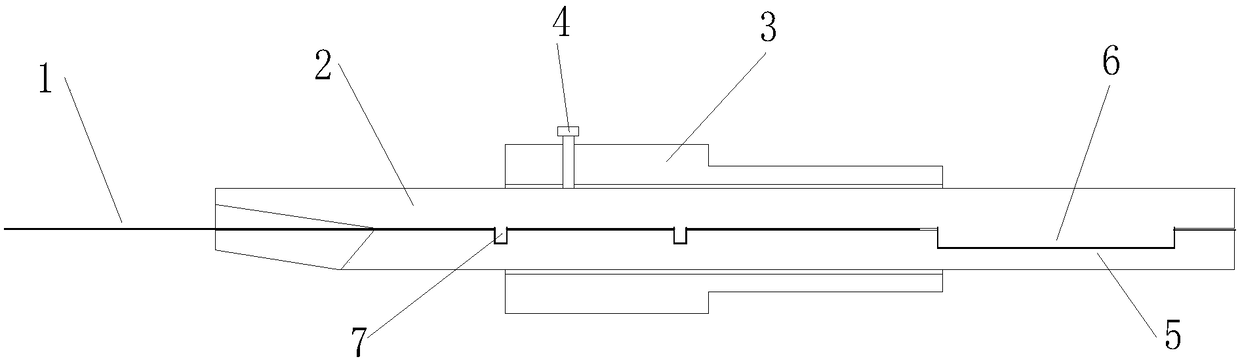

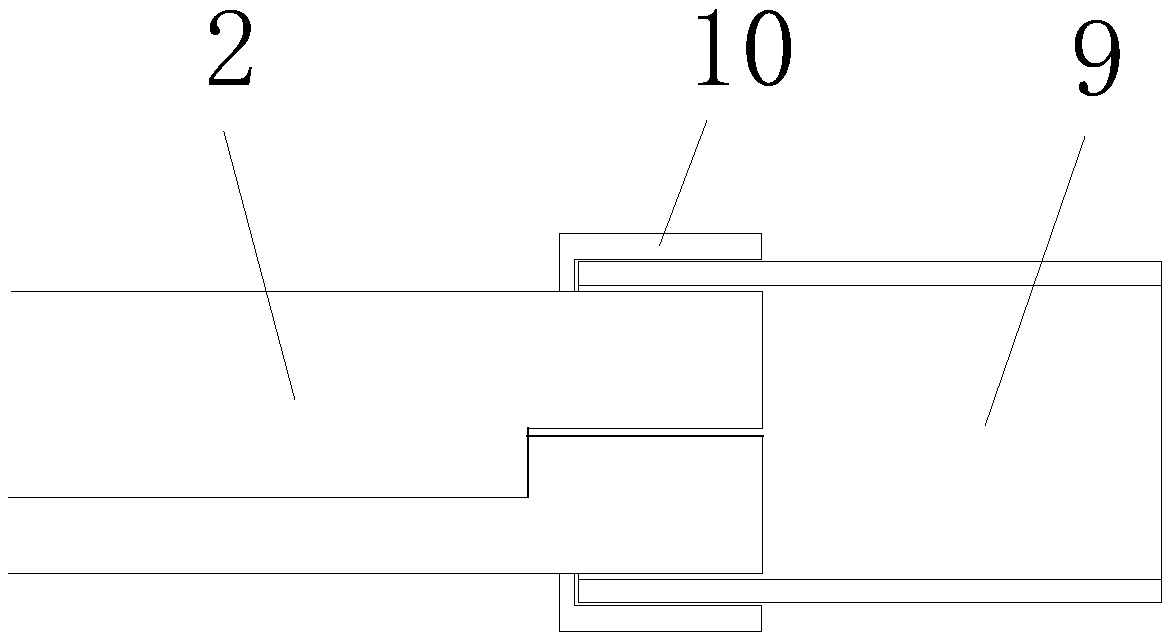

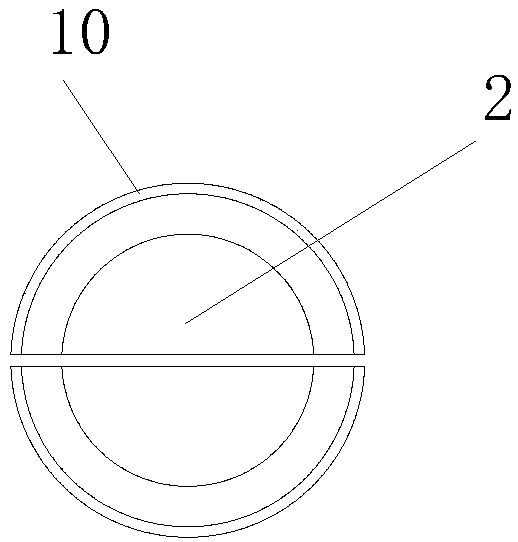

[0025] figure 1 The specific embodiment of the present invention is shown: a special tool for inspecting the air gap between the stator and rotor of a refrigerator compressor motor, including an air gap feeler gauge 1, a clamping handle 2 and a handle pressure sleeve 3, and the clamping handle 2 is a two-petal structure. The air gap feeler gauge 1 is set between the gaps of the clamping handle 2, the air gap feeler gauge 1 moves in the axial direction relative to the clamping handle 2, and the clamping handle 2 is wrapped by the handle pressing sleeve 3 to realize the air gap feeler gauge 1 relative to the clamping handle 2. The clamping handle 2 is fixed; the air gap feeler gauge 1 is an arc surface.

[0026] The handle sleeve 3 has a clearance fit with the clamping handle 2, and the handle sleeve 3 is provided with 4 holes for bolts, and the clamping force is applied to the clamping handle 2 through the bolts 4; one section of the assembly surface of the clamping handle 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com