Water-proof coiled material with self-adhesive layer structure

A technology of waterproof membrane and self-adhesive layer, applied in the direction of adhesives, building components, adhesive types, etc., can solve the problems of affecting product quality, affecting the quality of construction and the progress of the project, low bonding strength, etc. Product quality and service life, good practical value and social benefits, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

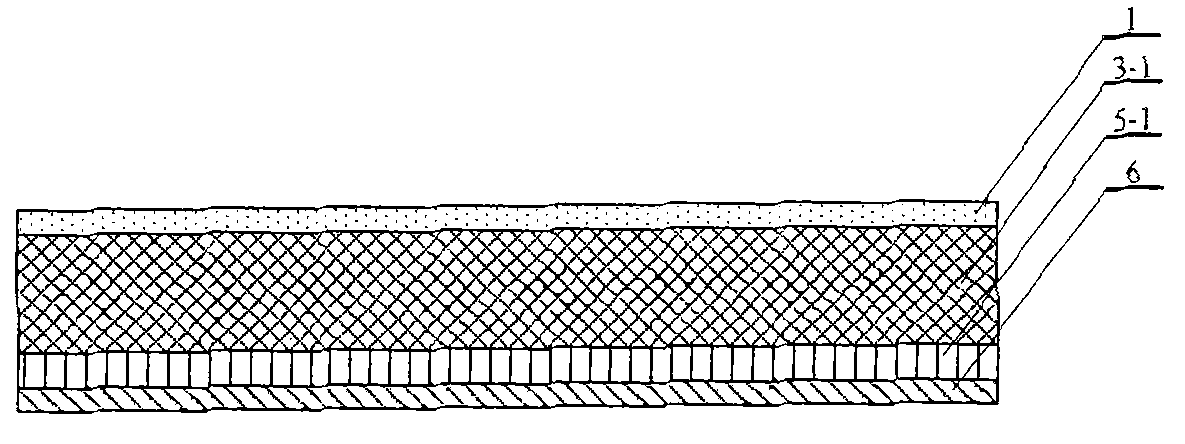

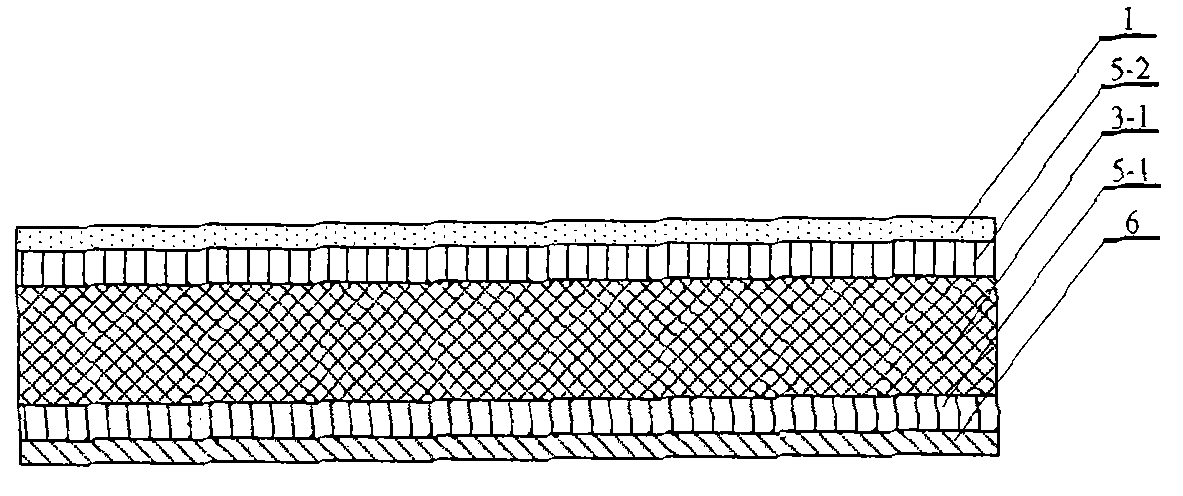

[0061] reference figure 1 with Figure 5 , To produce a tireless waterproof coiled material with an environmentally friendly wide temperature change self-adhesive layer on one surface of the present invention.

[0062] The face mask 1 and the plastic edge film 2 of the lap surface in this embodiment adopt the face mask and edge film material used in the waterproof roll material purchased on the market. The width of the face mask 1 is 800mm, and the width of the plastic edge film 2 of the lap surface is 120mm. . The first asphalt layer 3-1 and the second asphalt layer 3-2 use 90# petroleum asphalt. The lap surface plastic edge film 2 used in this embodiment is a commercially available anti-sticking PET film coated with silicone oil. The facial mask 1 of this embodiment is built with a self-adhesive layer. The lower surface composite base film 6 of the first environmentally-friendly wide-temperature self-adhesive layer 5-1 of this embodiment is the first environmentally-friendly w...

Embodiment 2

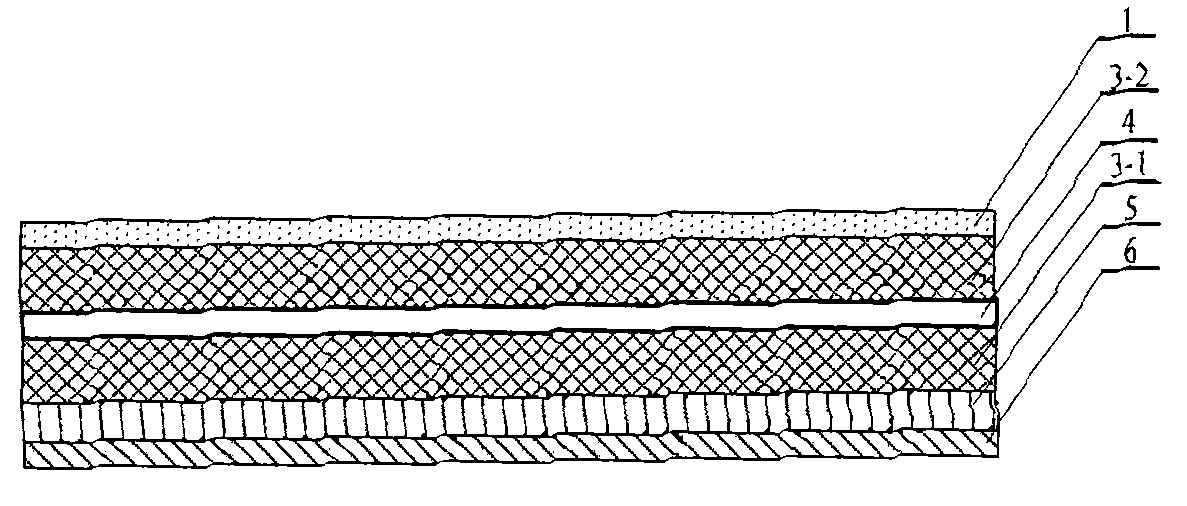

[0074] reference image 3 with 5 , To produce the self-adhesive layer structure waterproof membrane of the present invention, the self-adhesive layer waterproof membrane with an environmentally friendly wide temperature change with a tire is made of a non-woven polyester fabric purchased on the market as the tire base layer 4. The upper and lower surfaces of the base layer 4 are respectively coated with a first layer of asphalt 3-1 and a second layer of asphalt 3-2, and the other surface of the first asphalt layer 3-1 is compounded with a first environmentally friendly wide-temperature self-adhesive Layer 5-1 is compounded with the silicone oil-coated base film 6 on the lower surface of the first environmentally friendly wide temperature change self-adhesive layer 5-1; the other upper surface of the second asphalt layer 3-2 The middle position of the composite mask 1, that is, the width of the mask 1 is narrower than the second asphalt layer 3-2, that is, the width of the mask 1...

Embodiment 3

[0087] The manufacturing process and product structure of the environment-friendly wide-temperature-changeable self-adhesive layer waterproof membrane of this embodiment are the same as those of Embodiment 2, except that the tire base layer 4 is a glass fiber tire purchased on the market;

[0088] The first bitumen layer 3-1 and the second bitumen layer 3-2 are made of petroleum bitumen which can be used in the waterproofing membranes purchased on the market, APP resin and powder filler, or SBS resin and powder filler. Modified asphalt with a thickness of 0.5-3.5mm;

[0089] The thickness of the first environmentally friendly wide temperature change self-adhesive layer 5-1 is 0.2-1.5mm;

[0090] The adhesive used in the first environment-friendly and wide-temperature-change self-adhesive layer 5-1 of this embodiment is prepared by the following method:

[0091] 1) Adhesive raw material formula

[0092] The component A is: 115.0 parts by weight of deionized water;

[0093] The B componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com