A rotating body nozzle type reverser

A technology of commutator and rotating body, applied in the field of commutator, can solve the problems of high torque, rotor stuck, fragile, etc., and achieve the effect of improving service life, smooth rotation and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

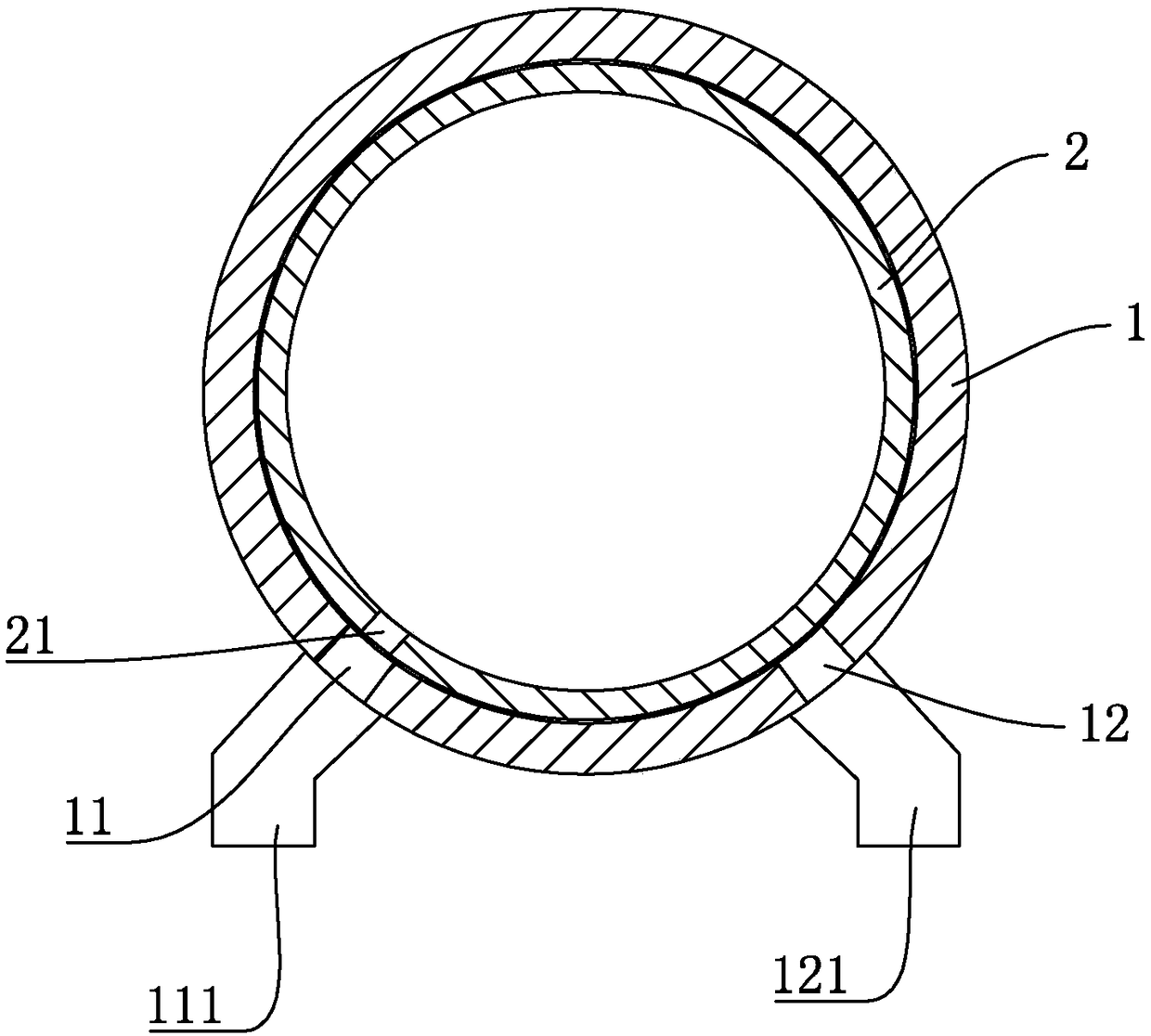

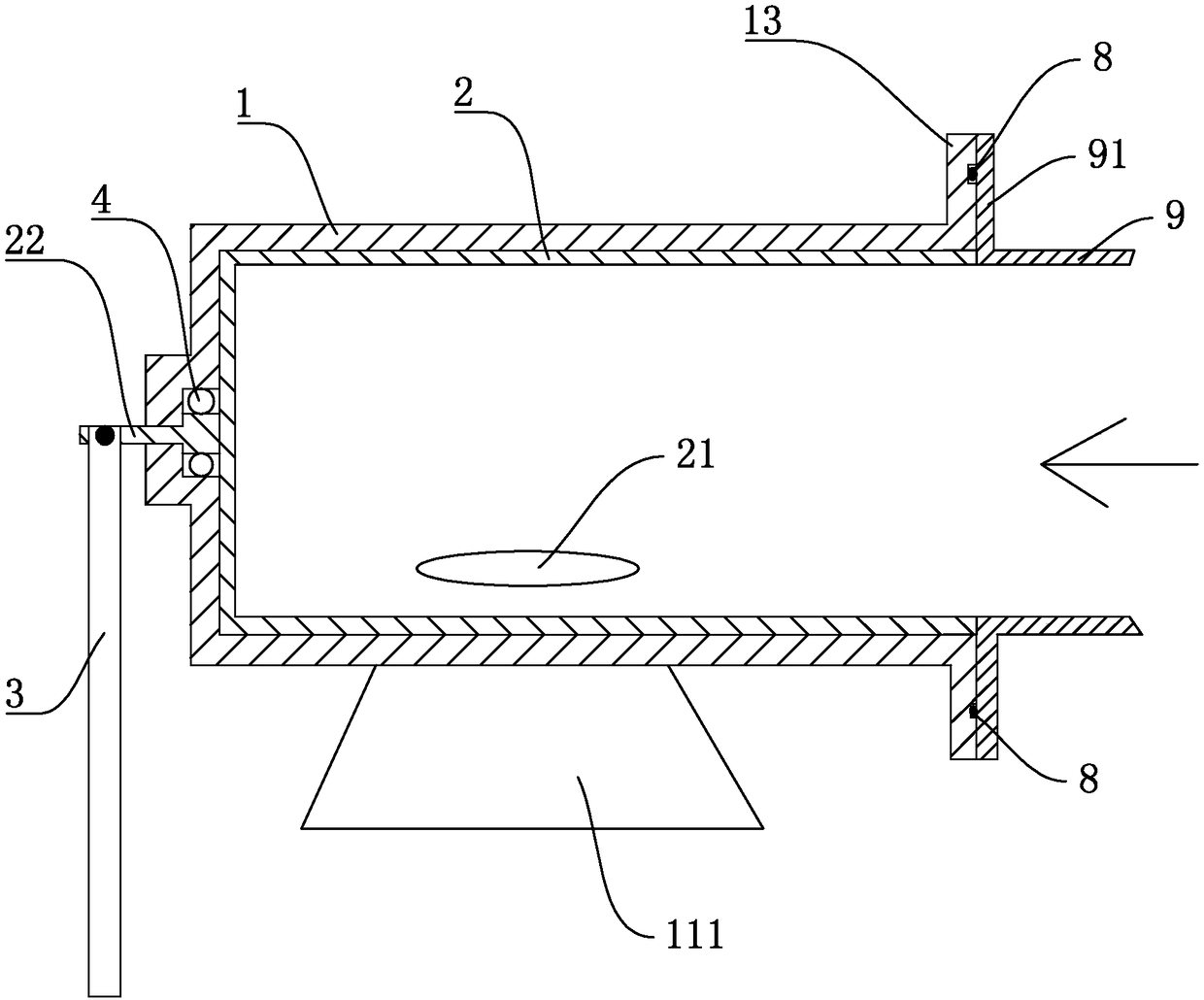

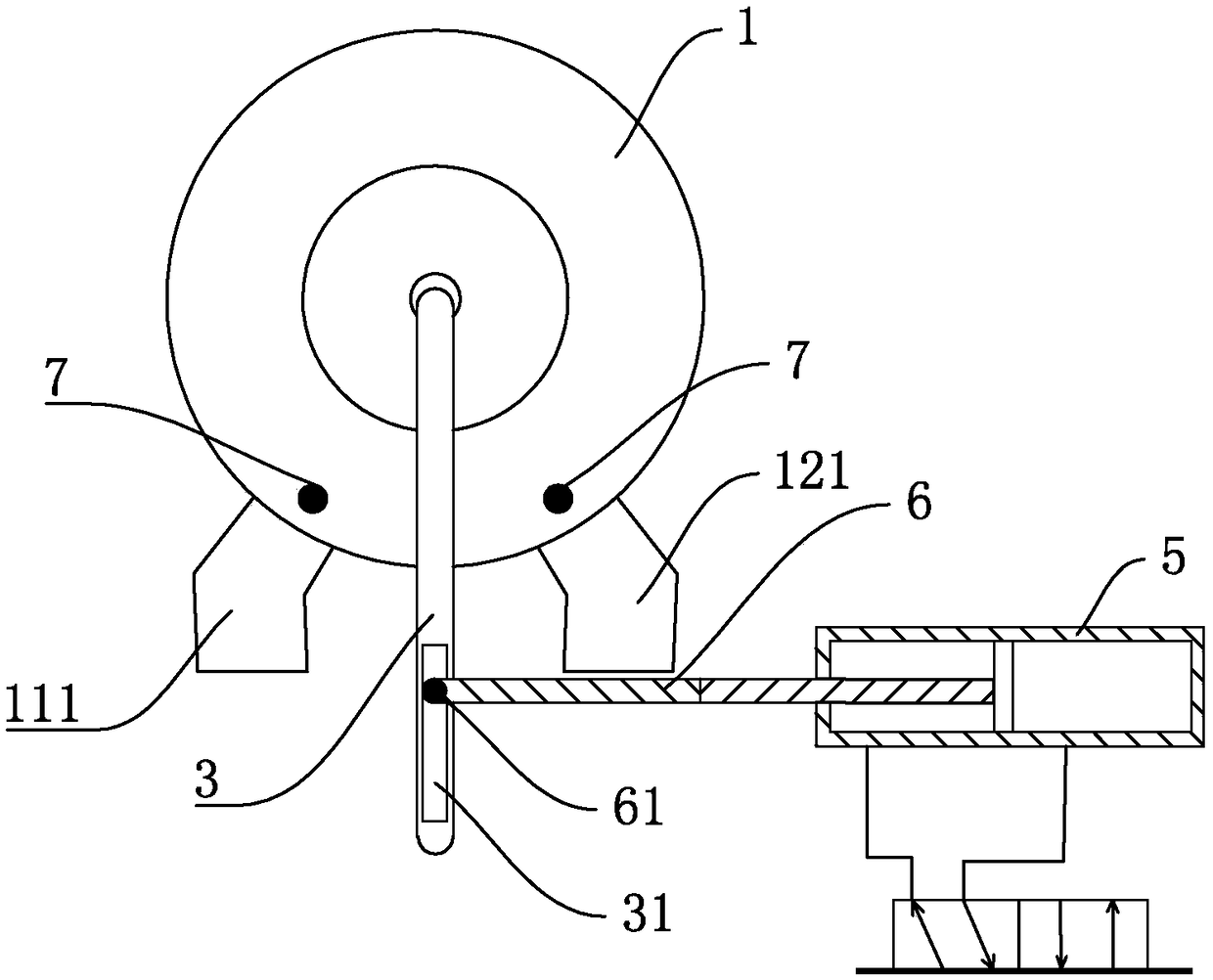

[0024] See attached figure 1 and 2 The rotary nozzle 21 type commutator includes a commutator main body 1 and a reversing rotary body 2. The cylindrical commutator main body 1 and the reversing rotary body 2 are arranged coaxially and rotated in cooperation. The commutator main body 1 The inner surface and the outer surface of the reversing rotating body 2 achieve the processing precision of liquid sealing and moving fit. A built-in nozzle 21 is provided on the reversing rotary body 2, and a first outlet 11 and a second outlet 12 on the same circumference as the nozzle 21 are provided on the commutator main body 1 along the direction of the commutator. The axis of the main body 1 is arranged symmetrically, so that when the commutator main body 1 rotates, the nozzle 21 can be aligned with the first outlet 11 or the second outlet 12 to realize the effect of changing the flow direction of the liquid. And in order to increase the sealing performance between the commutator main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com