Method for testing and evaluating sound absorbing and insulating performance of automotive acoustic package

An evaluation method, sound absorption and sound insulation technology, applied in vehicle testing, machine/structural component testing, analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problem of inability to comprehensively evaluate the NVH performance level of the entire vehicle, time-consuming, labor-intensive, and cost-intensive. Low test costs, simple test methods, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

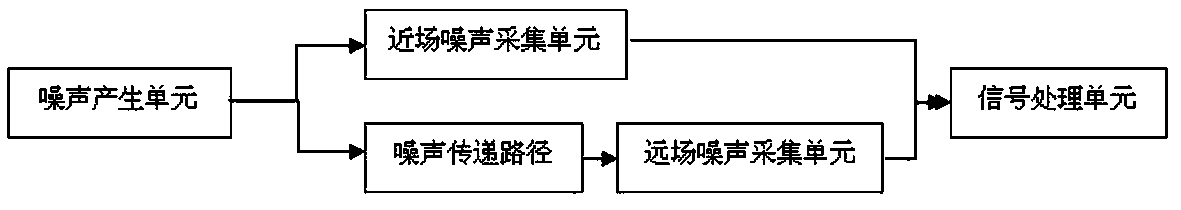

[0020] Such as figure 1 -3 shows a method for testing and evaluating the sound absorption and insulation performance of automotive acoustic packaging. The equipment includes a volume sound source that emits sound signals, a microphone that receives sound signals, and data acquisition equipment that records and processes sound signals. The volume sound The source output end is respectively connected to the input end of the signal processing unit through the near-field noise acquisition unit and the noise transmission path, and the far-field noise acquisition unit; the method includes the following steps:

[0021] (1) Place the whole vehicle in a full anechoic chamber (or semi-anechoic chamber);

[0022] (2) Arrange the volumetric sound source in the passenger compartment to emit white noise with a sound pressure level not lower than 100dB(A);

[0023] (3) Arrange the microphone at a specific position, connect it with the data acquisition device, and perform initialization sett...

Embodiment 2

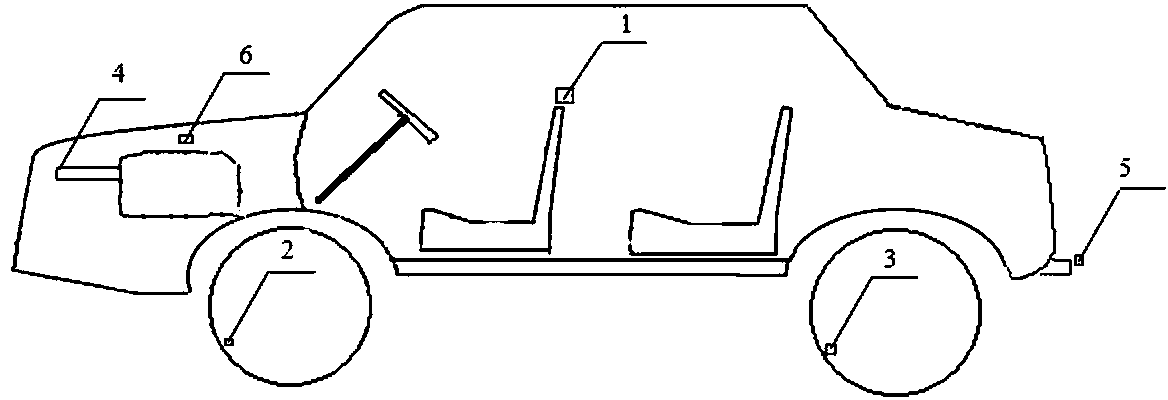

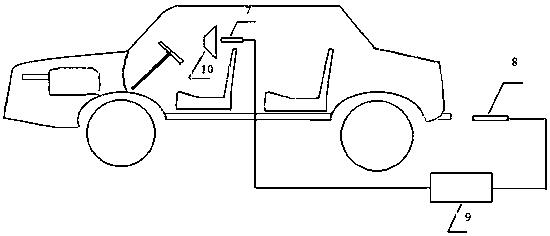

[0038] Such as image 3 As shown, 1 is the driver's right ear volume sound source, 2 is the front tire far-field microphone, 3 is the rear tire far-field sensor, 4 is the air intake far-field microphone, 5 is the exhaust port far-field microphone, 6 is the power The upper surface microphone of the assembly, 7 is the near-field noise collection unit of the volume sound source (with the volume sound source), 8 is the far-field noise collection unit (that is, the signal acquisition microphone after passing through each transmission path), and 9 is the signal processing unit ( That is, data acquisition equipment), 10 is a noise generating unit (that is, a volume sound source), and its connection method is the prior art, so it is omitted.

[0039] The white noise is emitted by the noise generating unit (volume sound source), and the sound signal of the noise generating unit is collected by a near-field noise acquisition unit (volume sound source belt) near the noise generating unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com