An ozone disinfection water preparation machine with an automatic control system for water outlet concentration

An automatic control system, ozone disinfection technology, applied in the direction of various fluid ratio control, mixer, mixer accessories, etc., can solve the problems that the precise control of ozone water concentration cannot be achieved, the adjustment method is too simple, and the concentration of the water outlet cannot reach the target, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

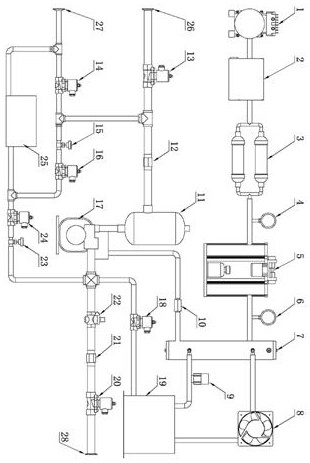

[0019] refer to figure 1 , the specific embodiment adopts the following technical solutions: ozone disinfection water preparation machine, including air pump 1, cold dryer 2, suction dryer 3, inlet pressure gauge 4, oxygen generator 5, outlet pressure gauge 6, ozone generation chamber 7. Condenser 8, water pump 9, ozone one-way valve 10, gas-liquid separation tank 11, outlet water flow switch 12, outlet solenoid valve 13, waste water solenoid valve 14, detection needle valve 15, detection solenoid valve 16, mixing pump 17. Water supply solenoid valve 18, water tank 19, water inlet solenoid valve 20, water inlet flow switch 21, pressure stabilizing valve 22, calibration needle valve 23, calibration solenoid valve 24, detector 25, ozone water outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com