Manufacturing process for touch screens

A manufacturing process and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of low production efficiency, achieve the effect of improving production efficiency and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

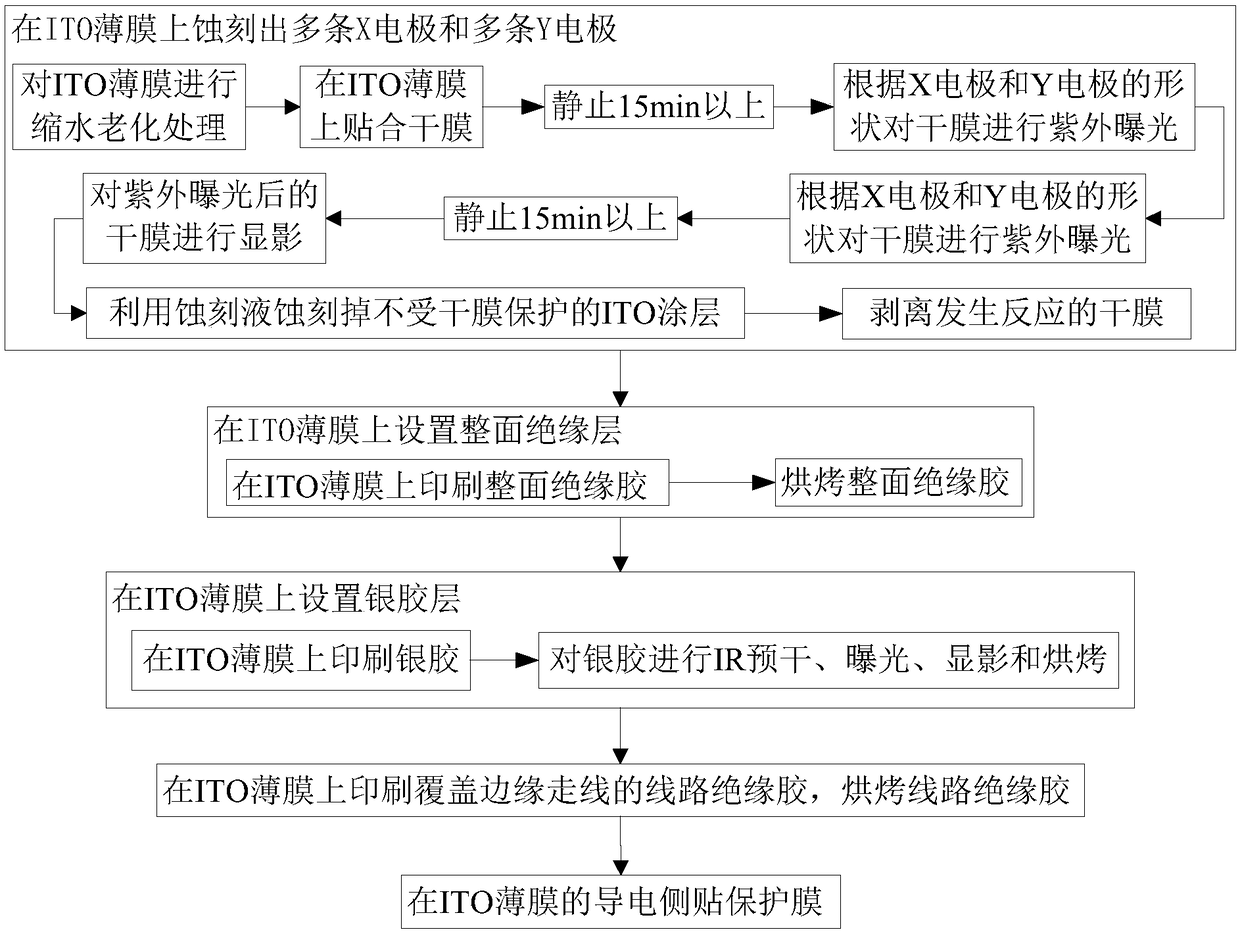

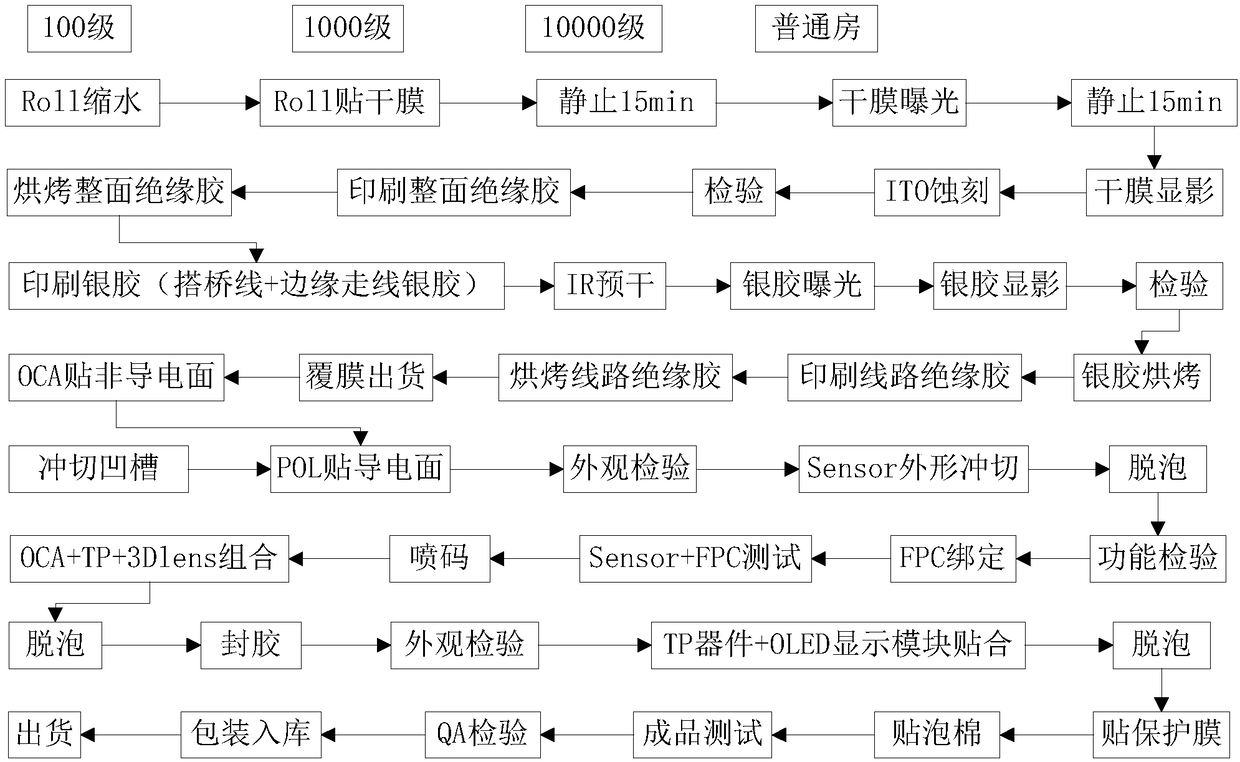

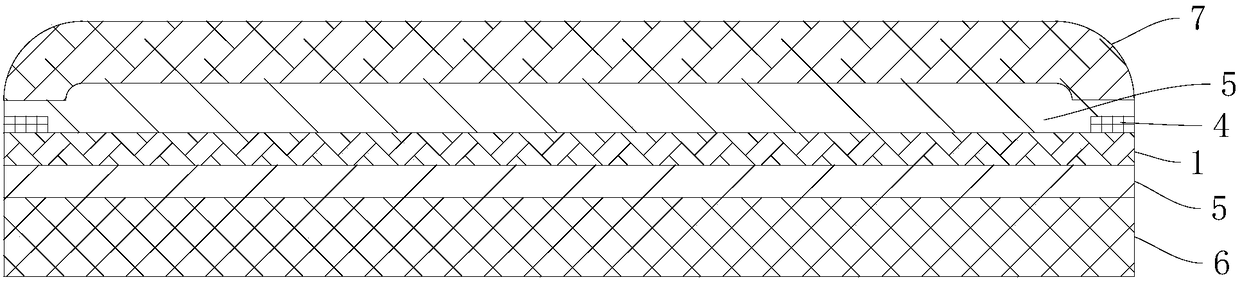

[0053] Further, see figure 1 As a specific implementation of the manufacturing process of the touch screen provided by the present invention, the step of disposing the entire insulating layer 2 on the ITO film 1 includes:

[0054] Print the entire surface insulating glue on the ITO film 1;

[0055] Bake the entire surface of insulating glue.

[0056] After printing the entire surface of the insulating glue on the ITO film 1, bake the entire surface of the insulating glue to obtain the entire surface of the insulating layer 2, which reduces the insulation pre-drying and exposure and development processes, and improves the production efficiency; the entire surface of the insulating layer 2 is printed and baked Set on the ITO film 1, it is easy to control the coverage area of the entire insulating layer 2, and the pressure during printing is small, which is beneficial to protect the ITO film 1. The entire insulating layer 2 formed by the printing process has strong adhesion to the ITO...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap