Assembling device of electrical connector

A technology for assembling equipment and electrical connection sheets, which is applied in the assembly/disassembly of contacts, manufacturing of contacts, etc., which can solve the problem that the functions are not perfect, cannot meet the diversified requirements of the assembly of electrical connection sheets, and does not specifically explain bolts and electrical connections. Sheet and metal tube feeding process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

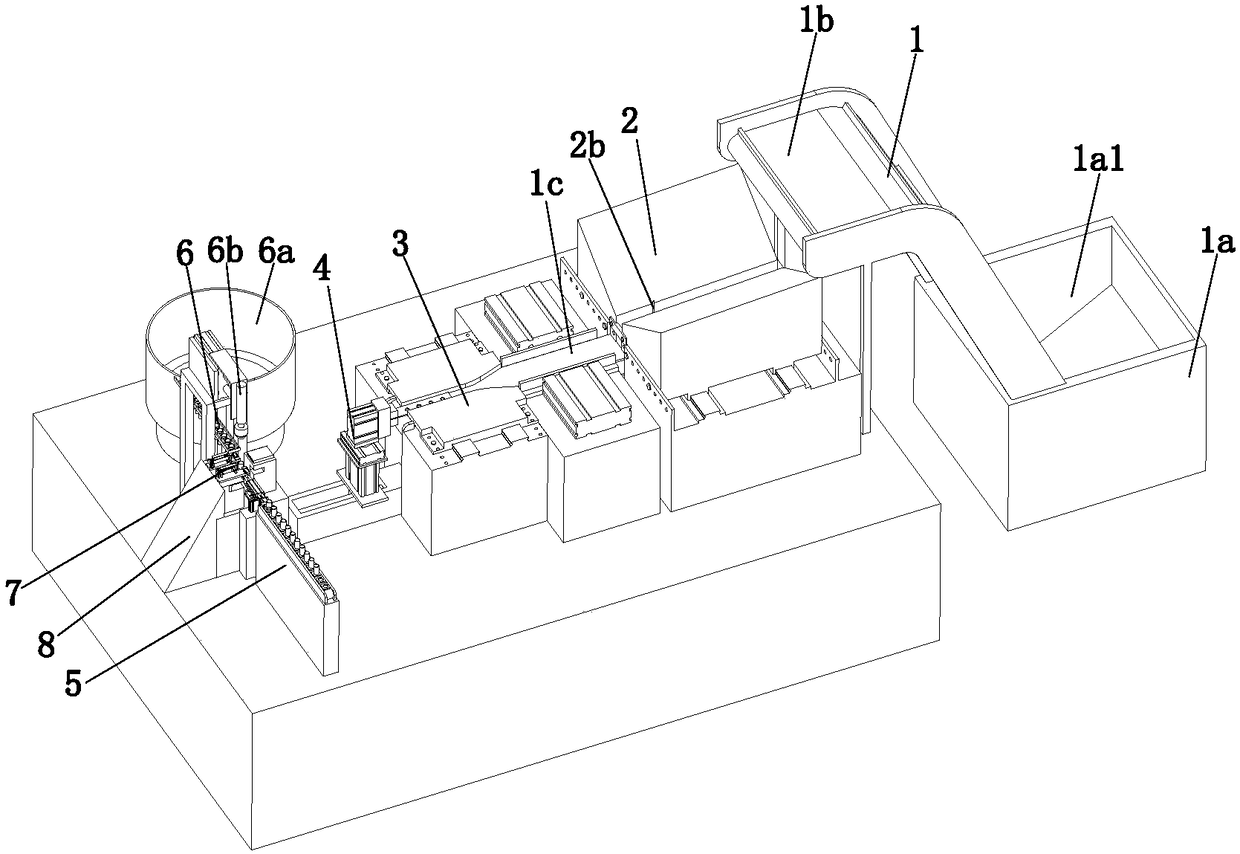

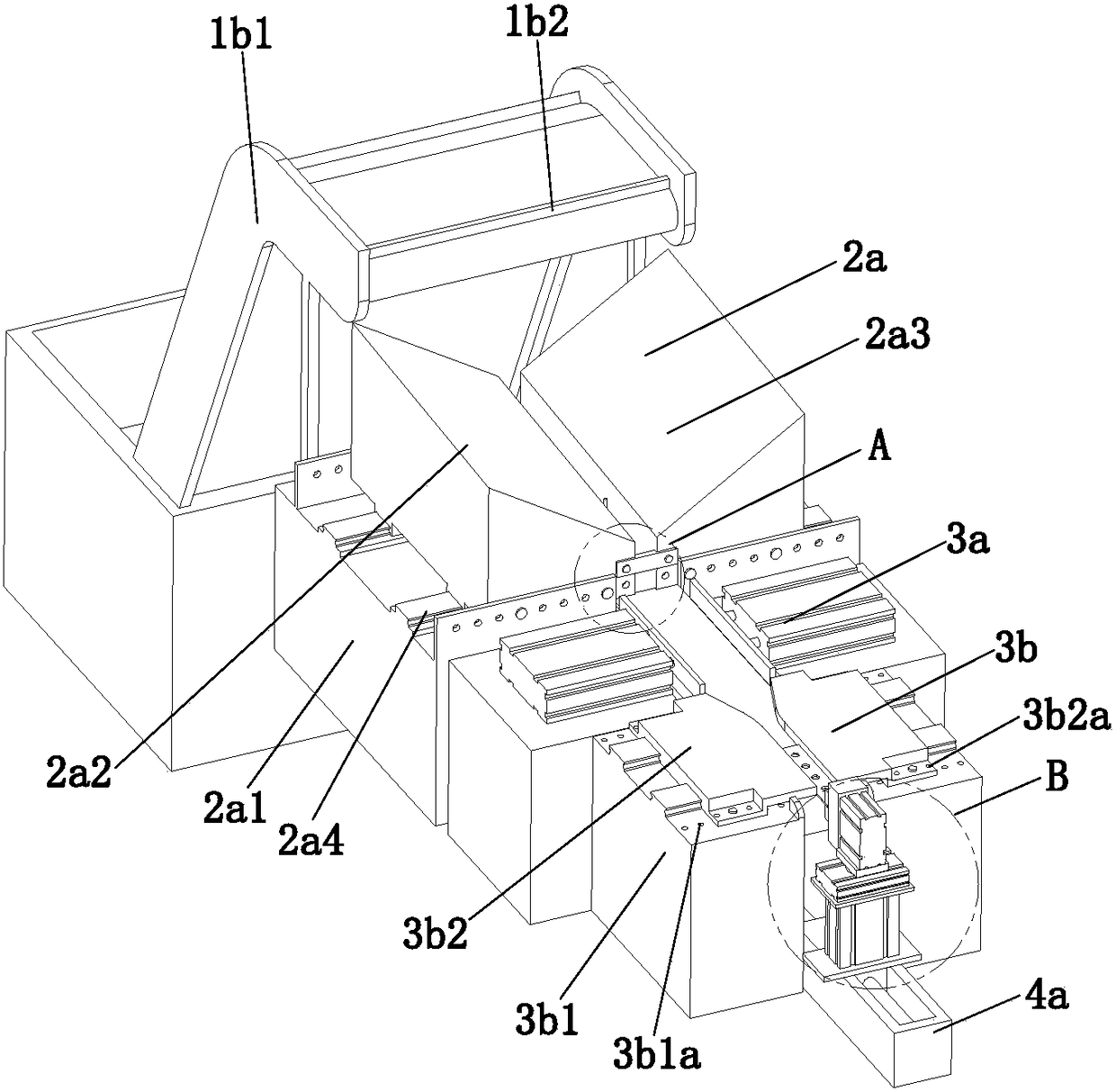

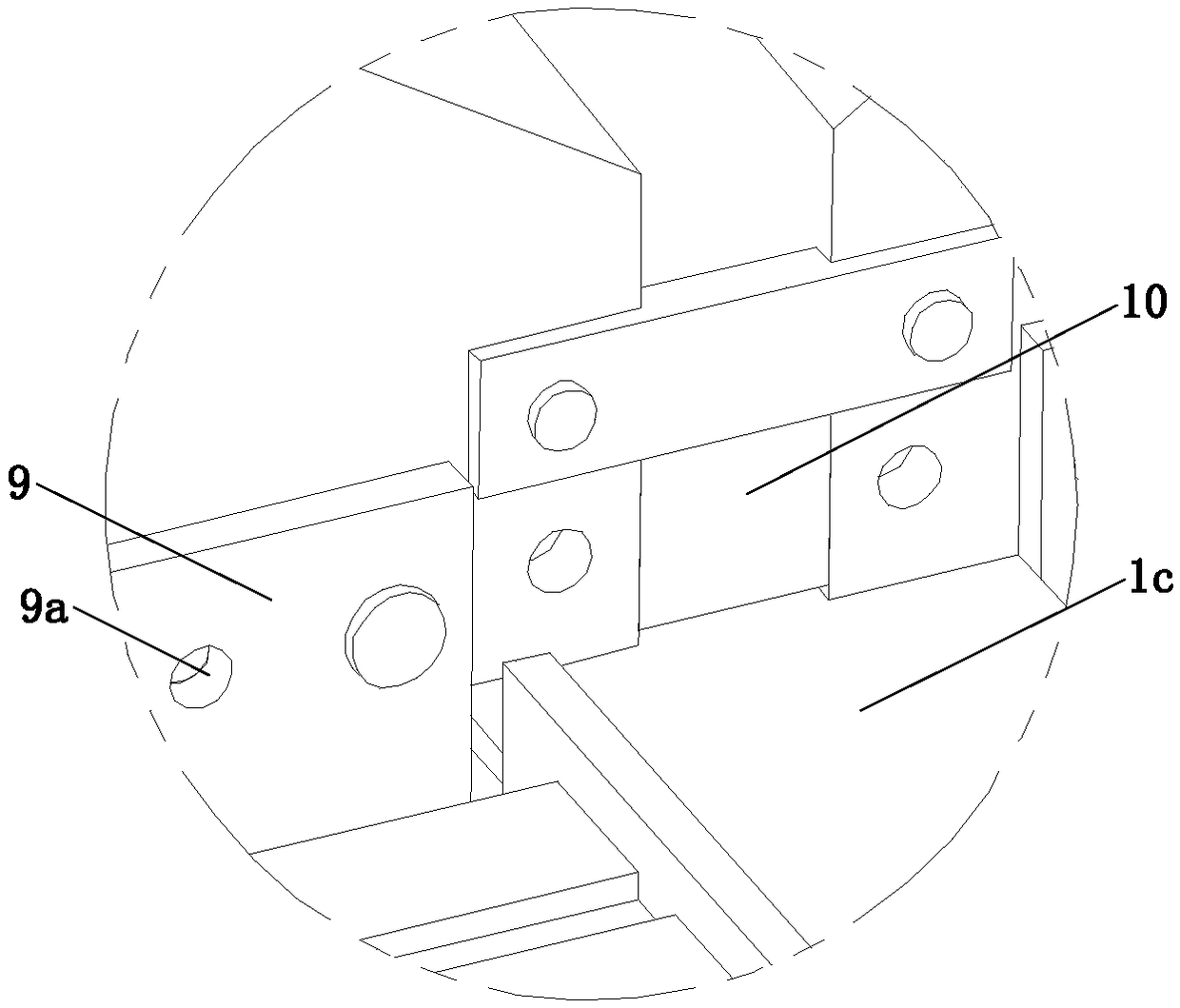

[0029] refer to Figure 1 to Figure 11An assembly device for electrical connectors, comprising a feeding mechanism 1, an orientation mechanism 2, a positioning mechanism 3, a first transfer mechanism 4, a second transfer mechanism 5, a bolt assembly mechanism 6 and a conveying mechanism 7, the orientation mechanism 2 and The positioning mechanism 3 is installed on both sides of the feeding mechanism 1, the first transfer mechanism 4 is located between the conveying mechanism 7 and the positioning mechanism 3, the bolt assembly mechanism 6 and the second transfer mechanism 5 are symmetrically arranged on both sides of the conveying mechanism 7, The conveying mechanism 7 includes a mounting base 7a, a fixed block 7b, a first conveying assembly 7c, a second conveying assembly 7d, and a pressing assembly 7e. On the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com