Reverse forming machine for braised pork

A forming machine and the technology of kneading meat, which is applied in the field of kneading meat reverse forming machine, can solve the problems of low serving efficiency, scalding palms and arms, affecting the taste and taste of kneading meat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail by specific embodiment now in conjunction with accompanying drawing:

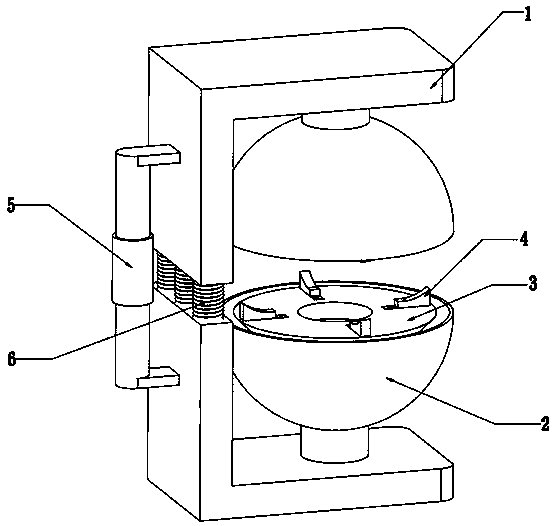

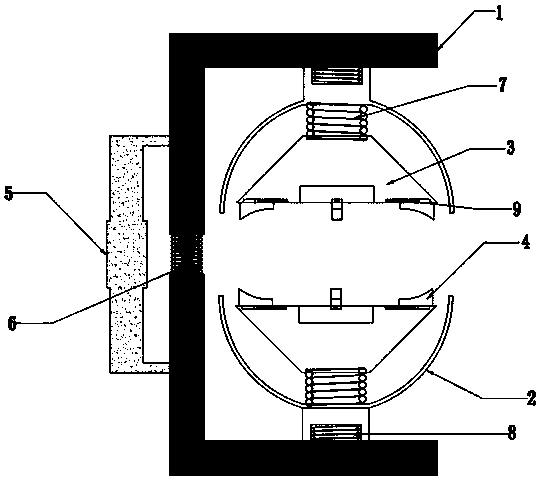

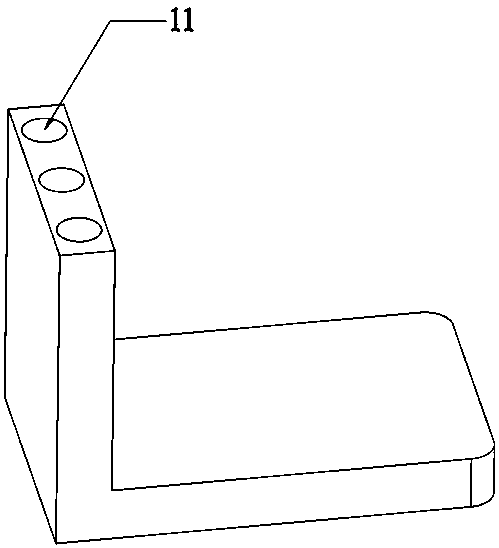

[0023] Such as Figure 1 to Figure 7 As shown, a buckle meat reverse molding machine, said buckle meat reverse molding machine includes a pressure plate (1), a bowl seat (2), a fixed seat (3), a clamp block (4), a handle (5), Pressing plate spring (6), fixed seat spring (7), bowl seat spring (8), clip spring (9); the number of the pressing plate (1) is two pieces, which are symmetrical to each other up and down; the bowl seat (2) is installed The inner side of the pressing plate (1) is connected and fixed with the bowl spring (8); the fixed seat (3) is installed in the bowl seat (2), and is connected and fixed with the fixed seat spring (7); The clamping block (4) is installed on the fixing seat (3), connected and fixed by the clamping block spring (9); the handle (5) is installed on the two pressing plates (1) The central positions of the pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com