Environment-friendly and sustainable full-module fabricated building system and construction method

A prefabricated and architectural technology, applied in the direction of architecture, building components, building structure, etc., can solve the problems of no modularization of prefabricated buildings, modularization of parts, inconvenience of integrated integration and industrialized production, etc., to facilitate industrialization. Reasonable production, function, overcoming the effect of complex construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

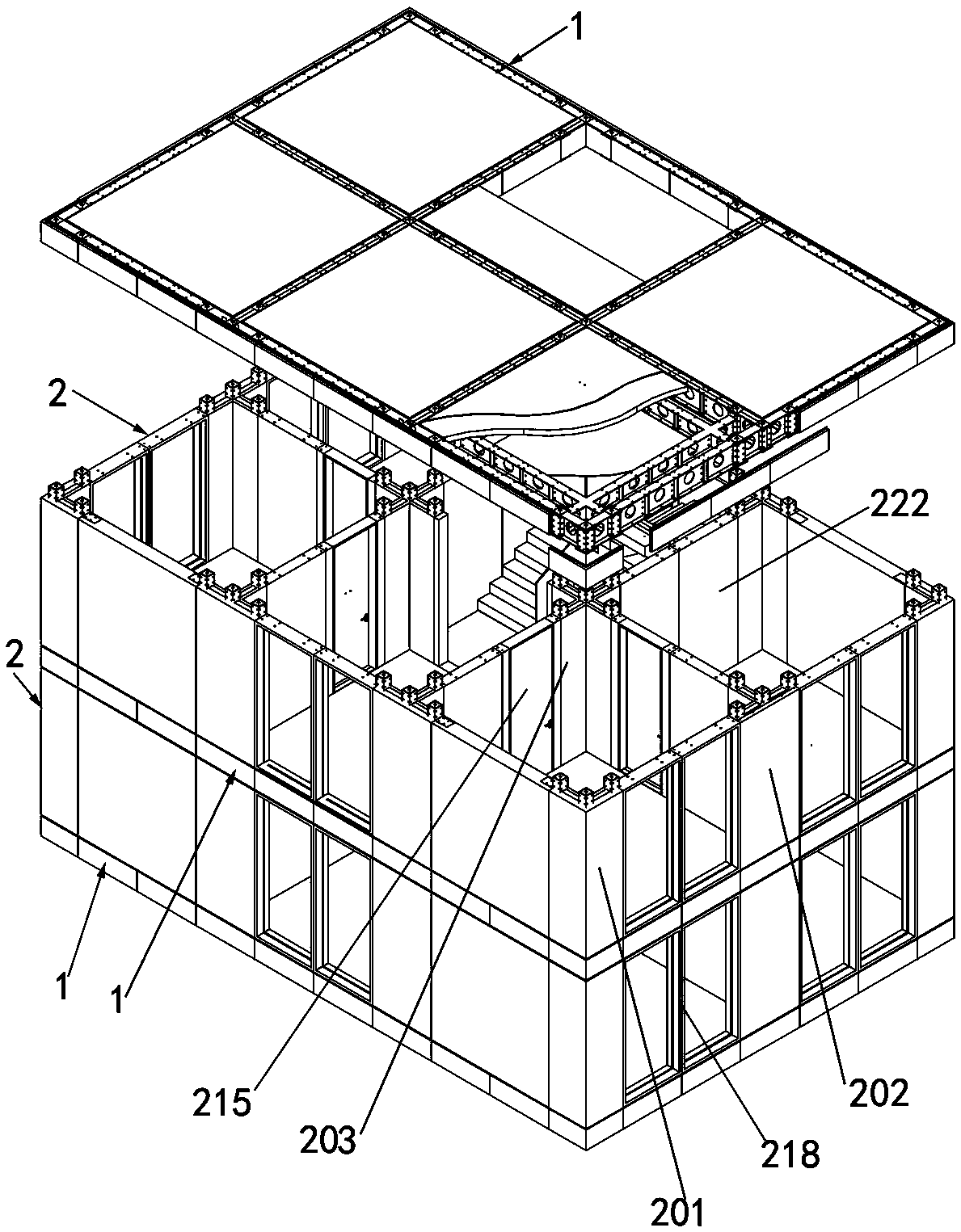

[0060] see figure 1 , the green sustainable full modular prefabricated building system includes a prefabricated floor 1 and a prefabricated wall 2 rigidly connected with the prefabricated floor. The prefabricated wall body 2 is assembled by prefabricated wall body modules, and a sealing body 214 is sandwiched between each prefabricated wall body module. The prefabricated wall module includes a prefabricated building column module and an enclosure module, wherein the enclosure module includes an enclosure door module, an enclosure window module and an enclosure wall module;

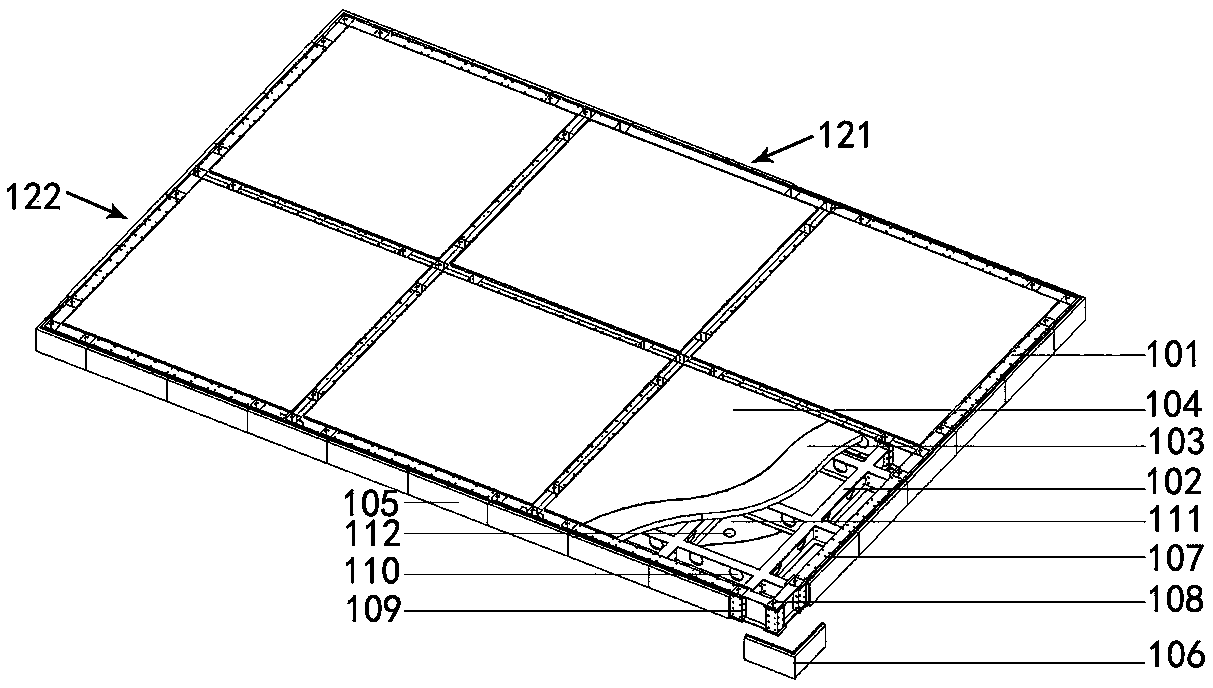

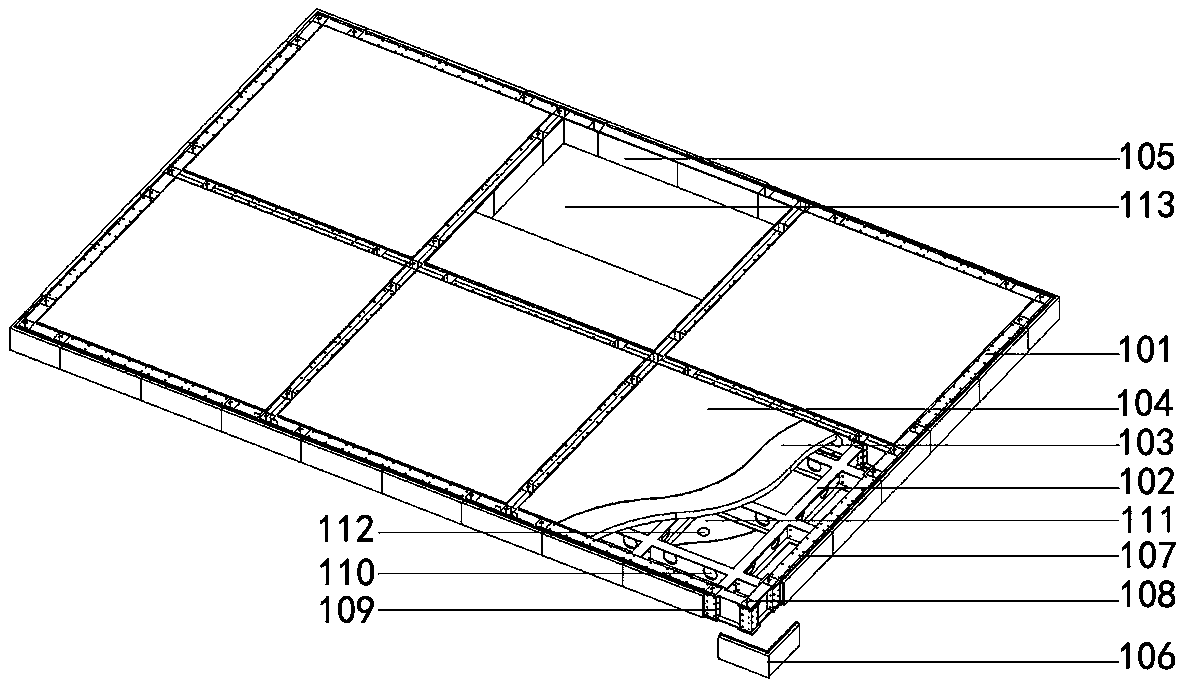

[0061] Embodiment one of prefabricated floor slab 1 sees figure 1 , figure 2 , the prefabricated floor 1 includes a main beam frame, a secondary beam frame and a floor layer 103, the main beam frame is a grid-like frame assembled by at least two modules, and the modules are a core module, a side module, and a corner module One or two or three or four or five of the inter-modules and single modules. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com