Adjustable two-way bearing block of textile machine

An adjustable, bearing seat technology applied in the direction of bearing elements, shafts and bearings, rigid supports for bearing components, etc., to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

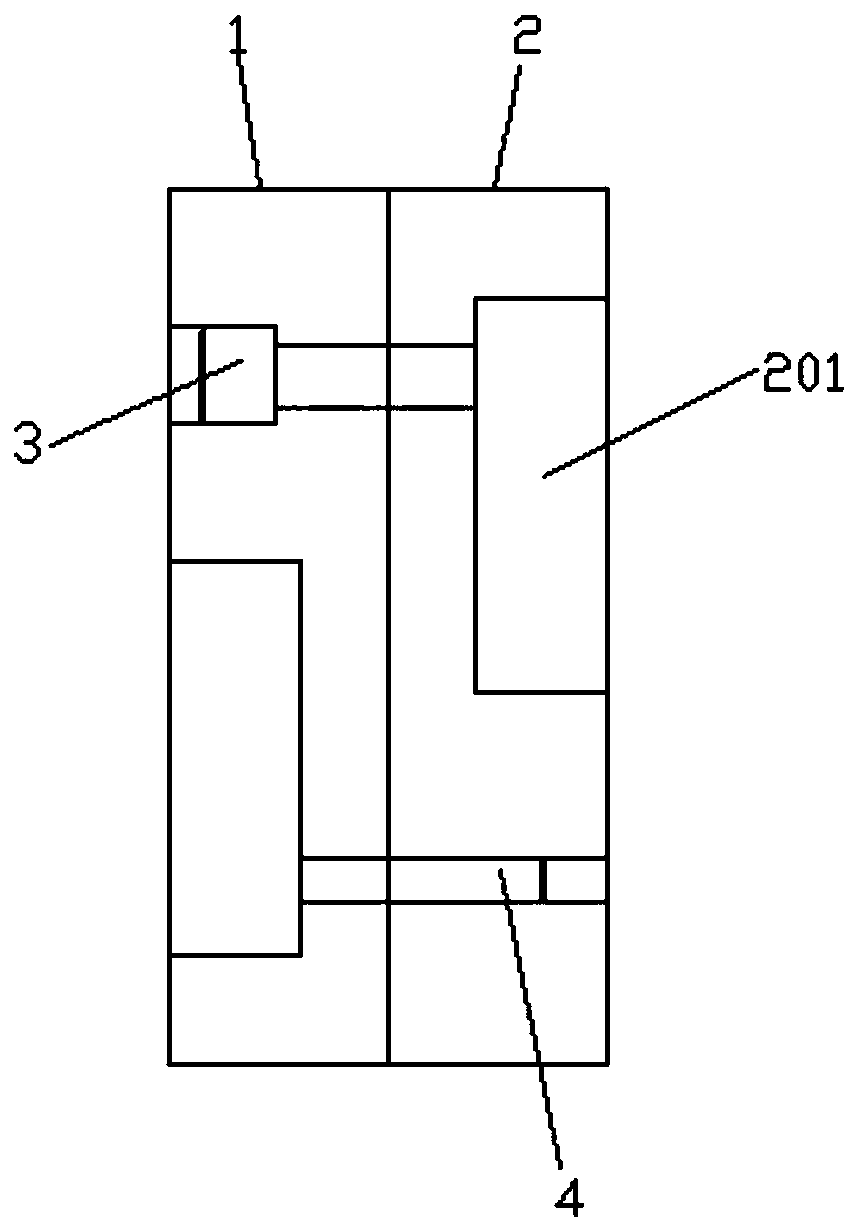

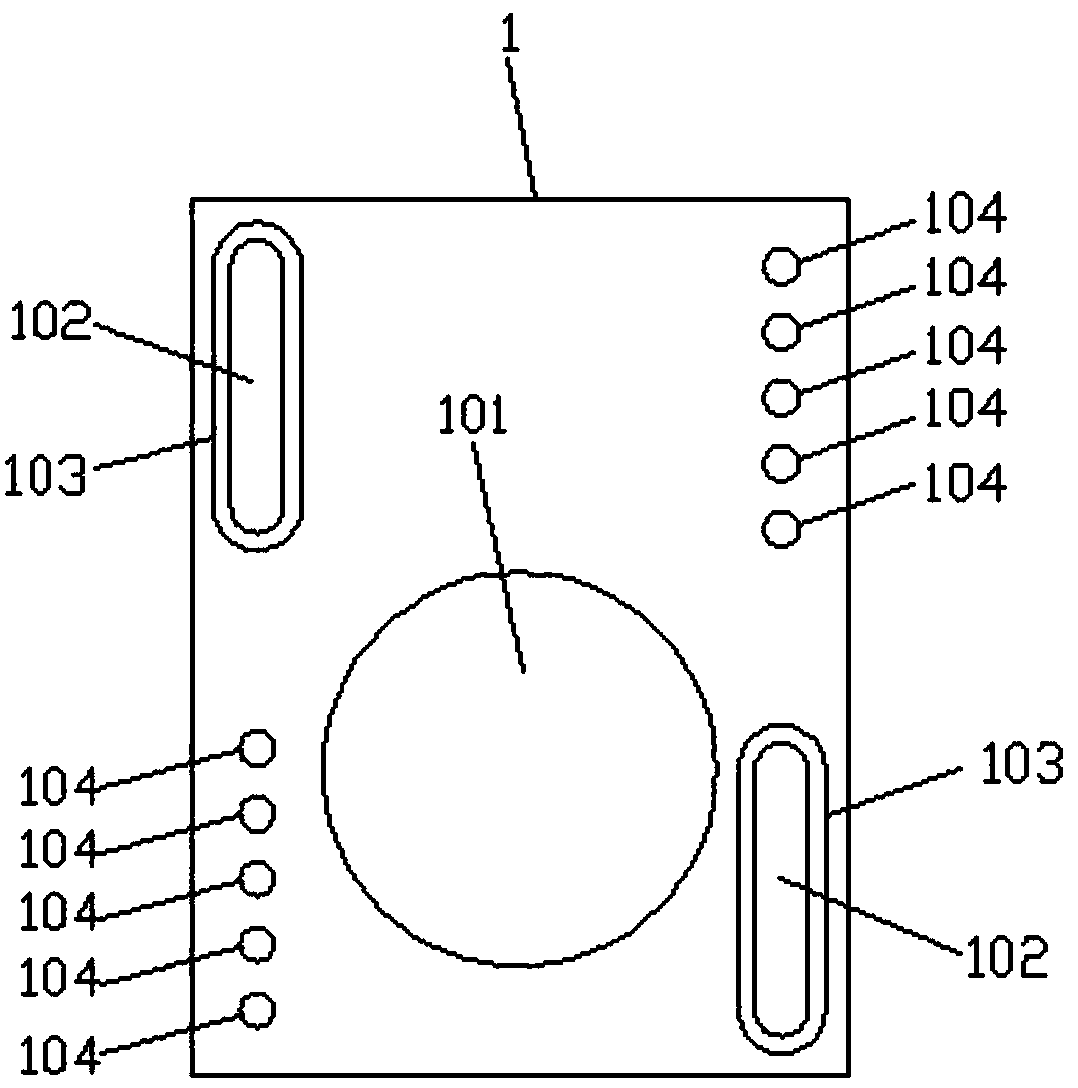

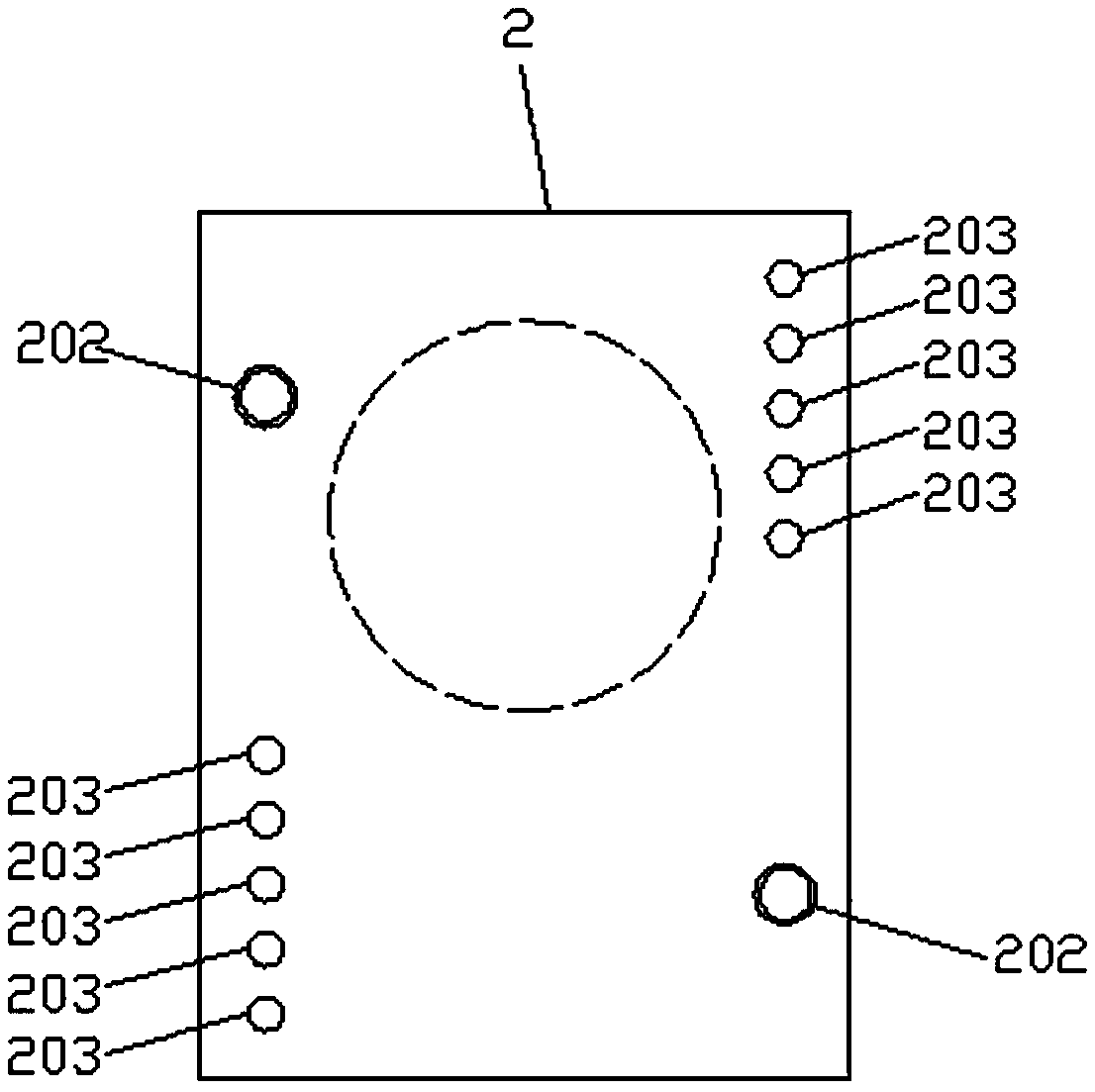

[0012] like Figure 1 ~ Figure 3 As shown, the adjustable two-way bearing seat of the textile machine includes a left support 1, a right support 2, a fixing screw 3, and a positioning pin 4. The left support 1 is provided with a bearing hole 101, and the upper left and lower right diagonally Long groove 102 is established, and some positioning holes one 104 are all established on the upper right and lower left corners of the other side, and sinkhole 103 is established in described long groove 102, and bearing hole two 201 is established in described right bearing 2, and screw hole two 201 is established in the upper left and lower right correspondingly. Holes 202, upper right and lower left are provided with some positioning holes 2 203, bearing hole 1 101 and bearing hole 2 201 directions of left supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com