A Tensile Shear Sample Preparation Tooling with Controllable Adhesive Thickness

A tensile shearing and adhesive technology, which is applied in the field of sample preparation methods and devices, can solve the problem of difficulty in controlling whether the thickness of the parallel and symmetrical adhesive layers of two laminates is uniform, lack of sample preparation methods and tooling, and low test results. problem, to achieve the effect of simple structure, avoid rotation, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

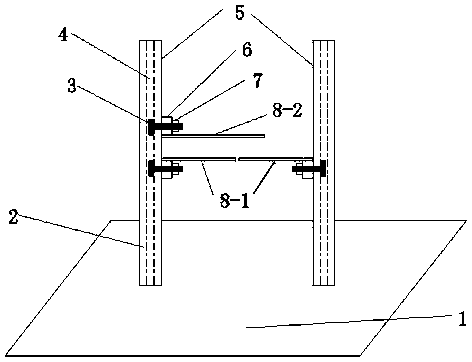

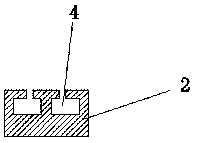

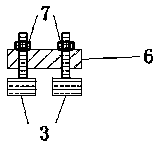

[0016] As shown in the figure, a tensile shear sample preparation tool with controllable adhesive thickness includes a bottom plate 1, a side plate 2, a horizontal support plate 8-1, a horizontal pressing plate 8-2 and a fastening device. The bottom plate 1 is a square Steel plate, and placed horizontally, the side plate 2 is made of steel plate, and two pieces are arranged, each piece is welded on the bottom plate 1 perpendicular to the bottom plate 1, and parallel grooves are respectively arranged on the opposite sides of the two side plates 2 Channel 4, the groove channel 4 is vertically arranged, and the groove channel 4 is a groove with a T-shaped cross section, and a scale 5 arranged along the groove channel 4 is also provided on the side plate 2, and the two sides The scales 5 on the plate 2 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com