Logistics cargo shifting device

A technology for transferring devices and goods, applied in the field of logistics, can solve the problem that the device cannot be rotated as a whole, and achieve the effect of convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

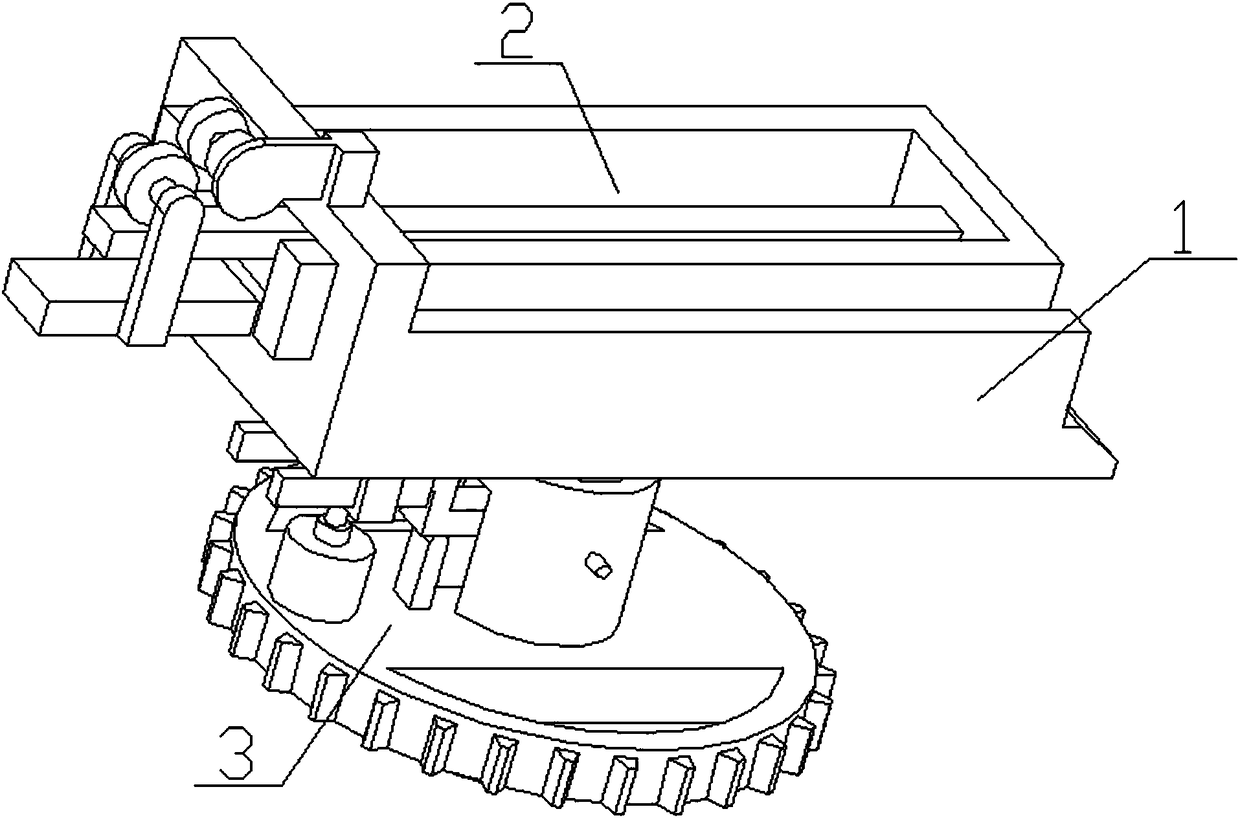

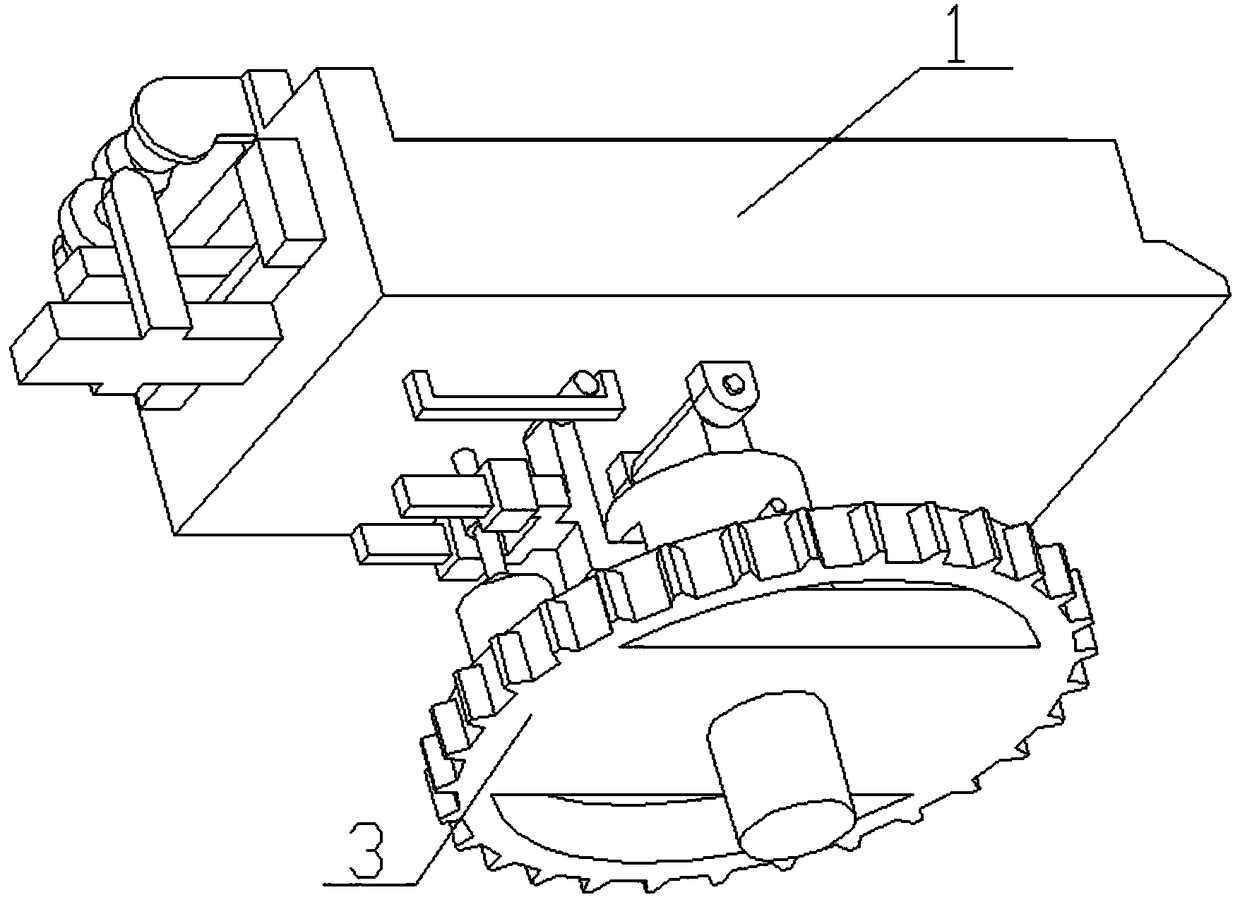

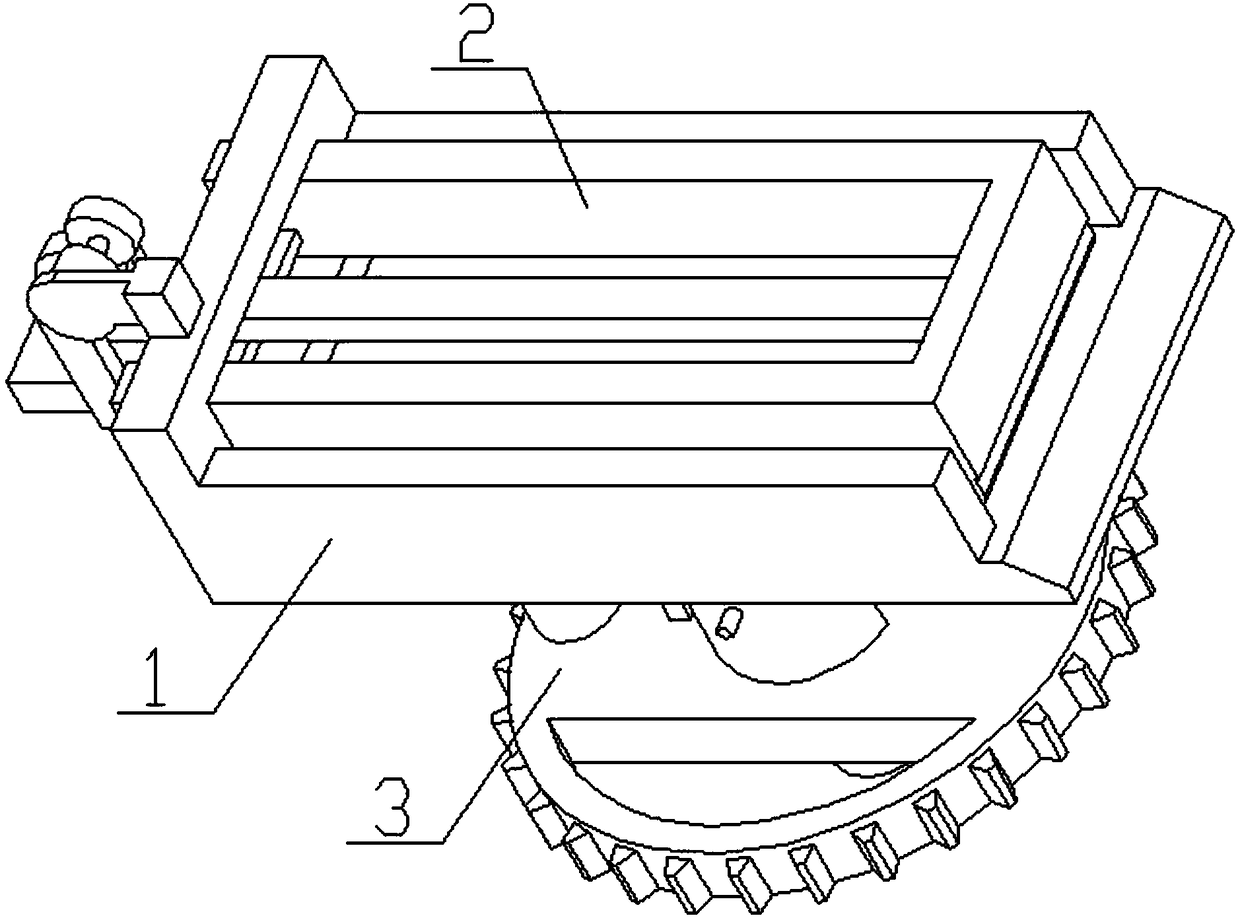

[0031] Combine below Figure 1-12 Describe this embodiment. The present invention relates to the field of logistics technology, more specifically, a logistics goods transfer device, including a loading assembly 1, a pushing assembly 2, and a transfer assembly 3. The entire device can rotate around the bottom axis to change the It is convenient to load and unload goods from different directions. The device drives the screw to rotate the motor to control the tilt of the bottom plate. The bottom plate is more linear when it is tilted, and it is easy to unload goods after the bottom plate is tilted. It is more convenient when unloading.

[0032] The loading assembly 1 includes a bottom plate 1-1, a side plate 1-2, a left baffle plate 1-4, a left horizontal plate 1-9, a rectangular chute 1-10, a chute frame 1-11 and a hinged seat 1 -12, the front and rear ends of the base plate 1-1 are fixedly connected with the side plate 1-2, the left end of the base plate 1-1 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com