A device for uniform feeding of forage for livestock

A technology for feeding devices and forages evenly, which is applied in animal husbandry, animal feeding devices, applications, etc., and can solve problems such as waste, uneven feeding, and large differences in the amount of forage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

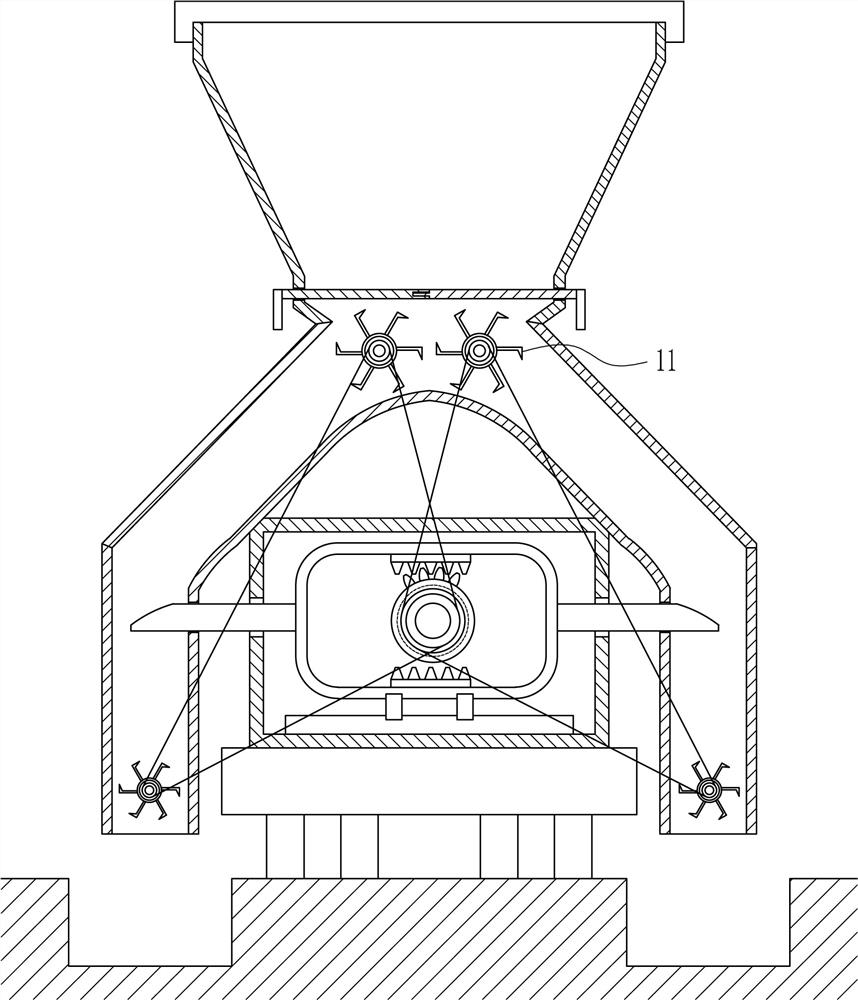

[0031] A device for evenly feeding grass for livestock, such as Figure 1-8 As shown, it includes a base 3, a roller 4, a uniform discharge mechanism 5, a frame 6, an inverted V-shaped drop tube 7, a switch mechanism 8, a storage tank 9 and a cover 10, and the bottom of the base 3 is equipped with a roller 4, and the base A frame 6 is installed on the top of the frame 6, and the front side of the frame 6 is an opening. A uniform discharge mechanism 5 is installed in the frame 6. An inverted V-shaped drop tube 7 is installed on the frame 6, and an inverted V-shaped drop tube 7 is installed on the frame 6. The material storage tank 9 is provided with a switch mechanism 8 at the bottom of the material storage tank 9, and the top of the material storage tank 9 is fitted with a cover 10 through a threaded connection.

Embodiment 2

[0033] A device for evenly feeding grass for livestock, such as Figure 1-8 As shown, it includes a base 3, a roller 4, a uniform discharge mechanism 5, a frame 6, an inverted V-shaped drop tube 7, a switch mechanism 8, a storage tank 9 and a cover 10, and the bottom of the base 3 is equipped with a roller 4, and the base A frame 6 is installed on the top of the frame 6, and the front side of the frame 6 is an opening. A uniform discharge mechanism 5 is installed in the frame 6. An inverted V-shaped drop tube 7 is installed on the frame 6, and an inverted V-shaped drop tube 7 is installed on the frame 6. The material storage tank 9 is provided with a switch mechanism 8 at the bottom of the material storage tank 9, and the top of the material storage tank 9 is fitted with a cover 10 through a threaded connection.

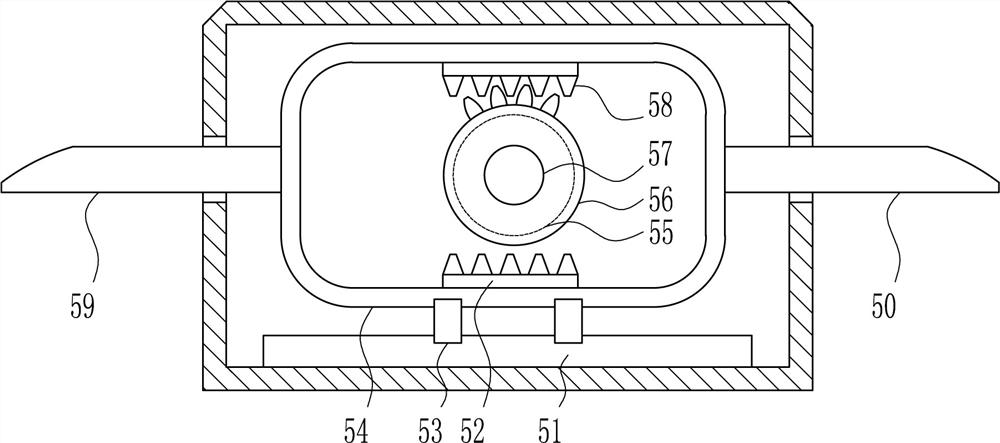

[0034] The even discharge mechanism 5 includes a right discharge plate 50, a slide rail 51, a lower rack 52, a slide block 53, a moving frame 54, a first motor 55, a...

Embodiment 3

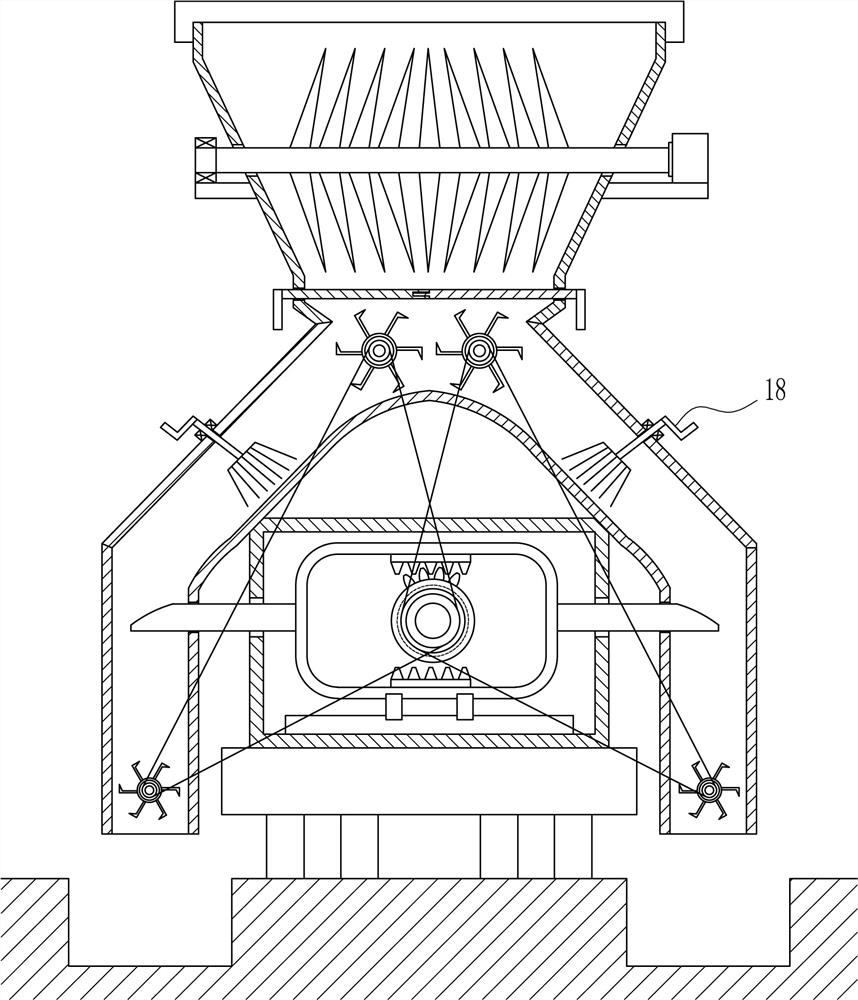

[0036] A device for evenly feeding grass for livestock, such as Figure 1-8 As shown, it includes a base 3, a roller 4, a uniform discharge mechanism 5, a frame 6, an inverted V-shaped drop tube 7, a switch mechanism 8, a storage tank 9 and a cover 10, and the bottom of the base 3 is equipped with a roller 4, and the base A frame 6 is installed on the top of the frame 6, and the front side of the frame 6 is an opening. A uniform discharge mechanism 5 is installed in the frame 6. An inverted V-shaped drop tube 7 is installed on the frame 6, and an inverted V-shaped drop tube 7 is installed on the frame 6. The material storage tank 9 is provided with a switch mechanism 8 at the bottom of the material storage tank 9, and the top of the material storage tank 9 is fitted with a cover 10 through a threaded connection.

[0037] The even discharge mechanism 5 includes a right discharge plate 50, a slide rail 51, a lower rack 52, a slide block 53, a moving frame 54, a first motor 55, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com