Cutting blade and manufacturing method thereof

A cutting blade and blade technology, applied in the field of blades, can solve the problems of increasing the workload and psychological pressure of operators, unbalanced cutting blade weight, rough cutting surface, etc., achieve long-term stable cutting performance, prevent low strength, and solve weight imbalance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below based on the drawings.

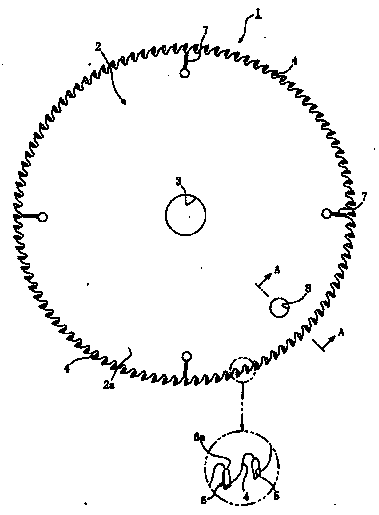

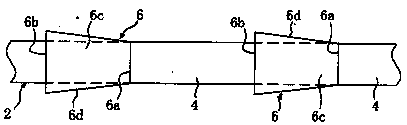

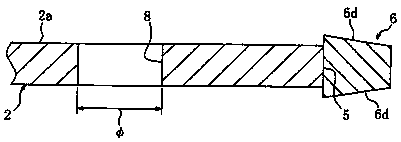

[0029] Figure 1~Figure 3 It is an embodiment of the dicing blade related to the present invention. Such as figure 1 As shown, the cutting blade 1 is a base metal 2 having a disc shape formed by pressing a carbon steel plate or the like, and a mounting hole 3 for mounting to a cutting machine (not shown) is formed at the center. On the outer peripheral edge portion 2a of the base metal 2, for example, a knife chamber 4 recessed in the direction of the mounting hole 3 and a blade fixing portion 5 formed by a step or a concave portion are provided at a certain interval in the circumferential direction, and the blades are fixed on each blade. The parts 5 are respectively brazed and fixed with inserts 6 made of, for example, cemented carbide.

[0030] The blade 6 is composed of an approximately L-shaped or approximately U-shaped fixed surface 6a in a plan view corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com