Multi-cabin-section combined type butt-joint transfer car

A transfer vehicle and combined technology, which is applied in the direction of motor vehicles, vehicle parts, traction connectors, etc., can solve the problems of high requirements on transportation routes, inflexible transfer of combined cabins, and long lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

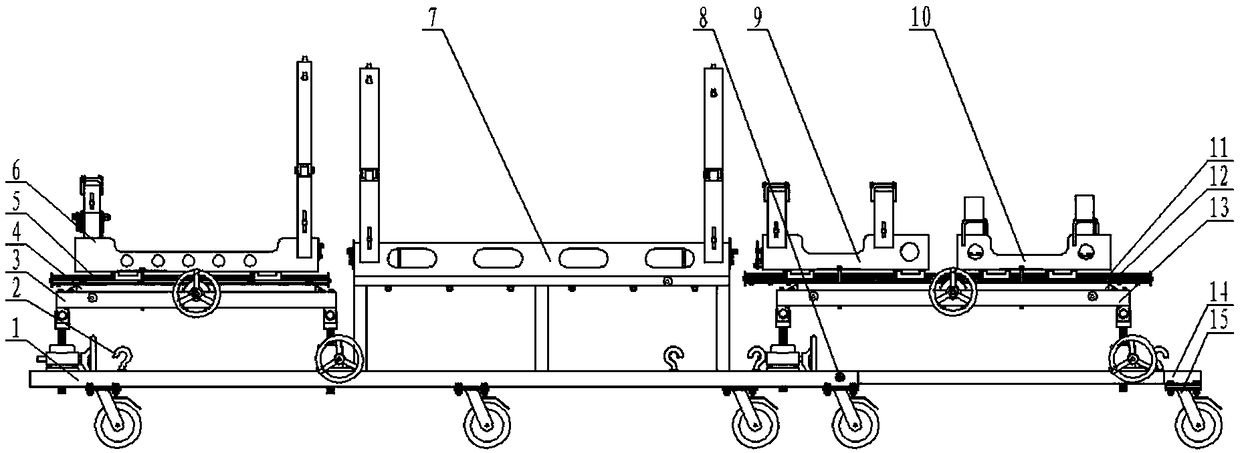

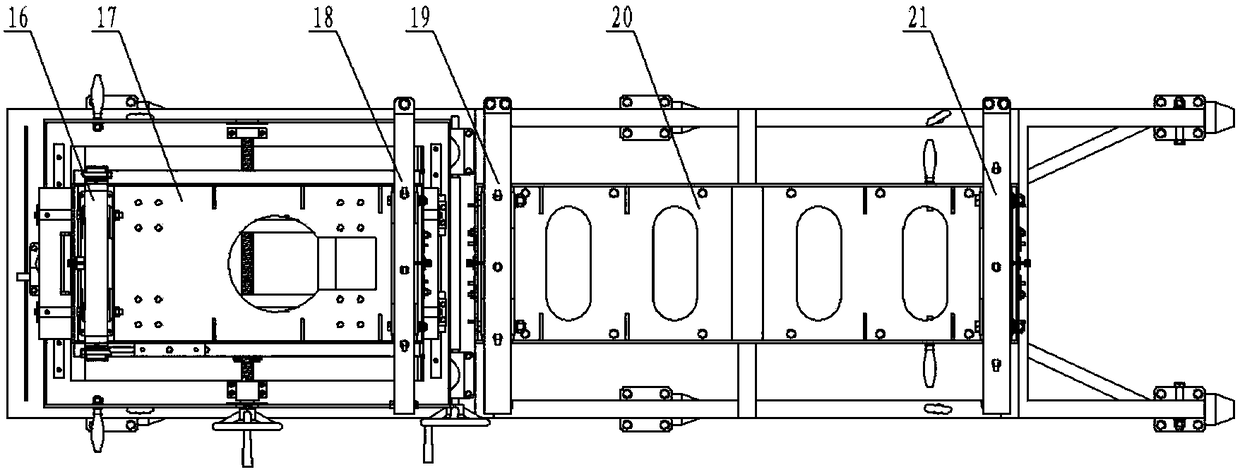

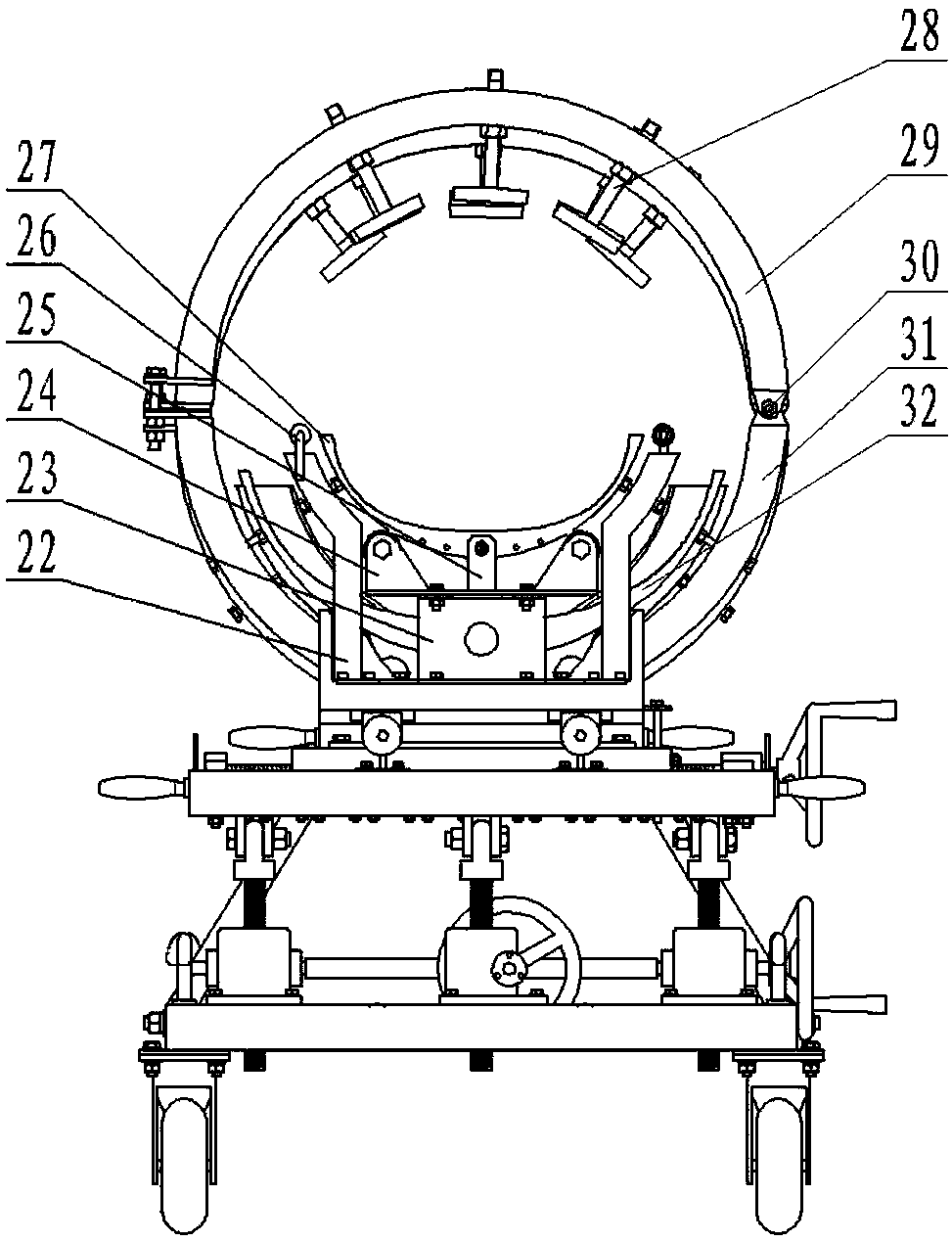

[0022] A multi-chamber combined docking transfer vehicle, characterized in that: it includes a main docking vehicle, an auxiliary docking vehicle and a vehicle body docking fastening device, and the main docking vehicle and the auxiliary docking vehicle are connected through the vehicle body docking fastening device; The main docking vehicle is composed of the main vehicle frame 1, the attitude adjustment system, the first cabin section bearing system 6, the second cabin section loading system 7 and the main vehicle body docking device, and the first cabin section is set above the main vehicle frame 1 The bearing system 6 and the second compartment bearing system 7, and an attitude adjustment system is arranged between the first cabin bearing system 6 and the main vehicle frame 1;

[0023] The auxiliary docking vehicle is composed of an auxiliary vehicle frame 14, an auxiliary vehicle attitude adjustment system, a third cabin loading system 9, a fourth cabin loading system 10 a...

Embodiment 2

[0030] The main docking car and the auxiliary docking car can quickly complete the docking through the docking device and the fastening device, realizing the overall intermodal function. Two conical docking holes matching the fast docking cone 33 of the auxiliary docking car are processed on the rear beam of the main docking car, and two oblique ribs are welded at the rear, the welding angle is the same as that of the front of the auxiliary docking car, taking into account the docking guide and reinforcement of the car body Function, after the auxiliary docking vehicle and the main docking vehicle realize rapid docking, install a C-type gasket at the end of the docking cone and fasten it with bolts. Two through holes with a diameter of 14.5mm are processed on the left and right sides of the main docking car and the auxiliary docking car. After the main docking car and the auxiliary docking car are docked, bolts are used to fasten them to ensure the reliability of the docking an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com