Filler storage case for sewage treatment

A sewage treatment and frame technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of frame deformation, space occupation, low transportation efficiency, etc., and achieve load-bearing performance improvement , reduced volume, convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

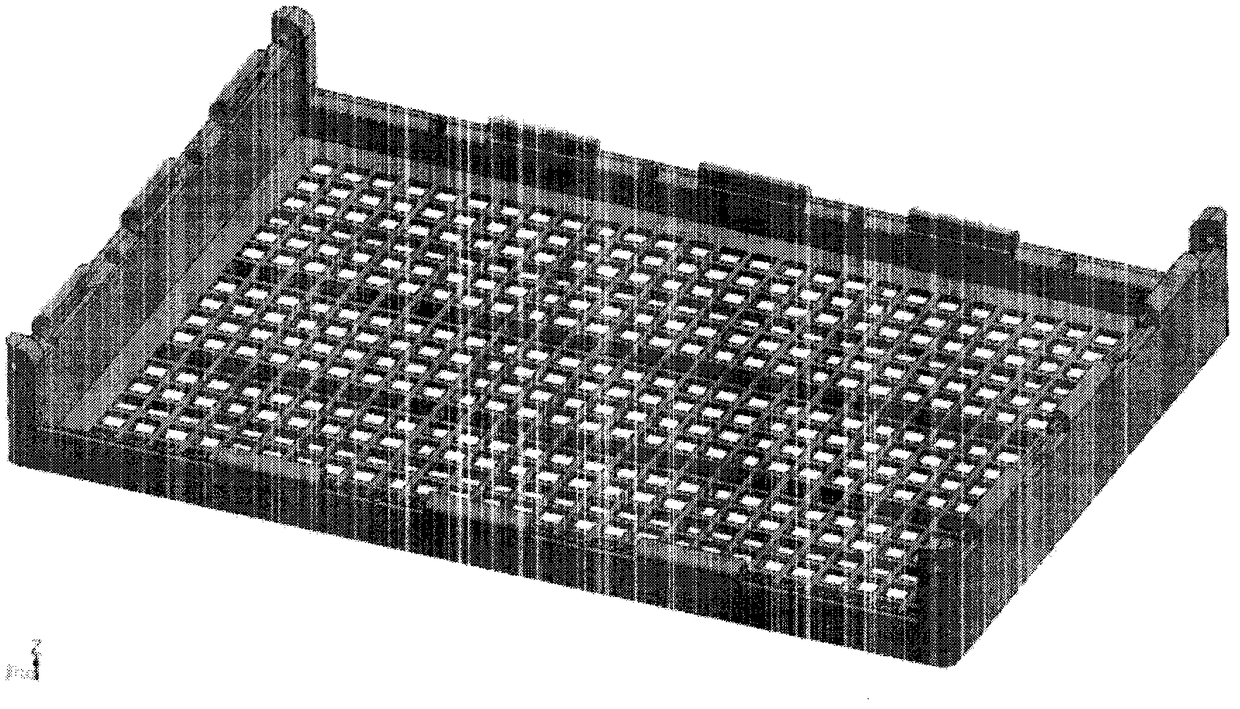

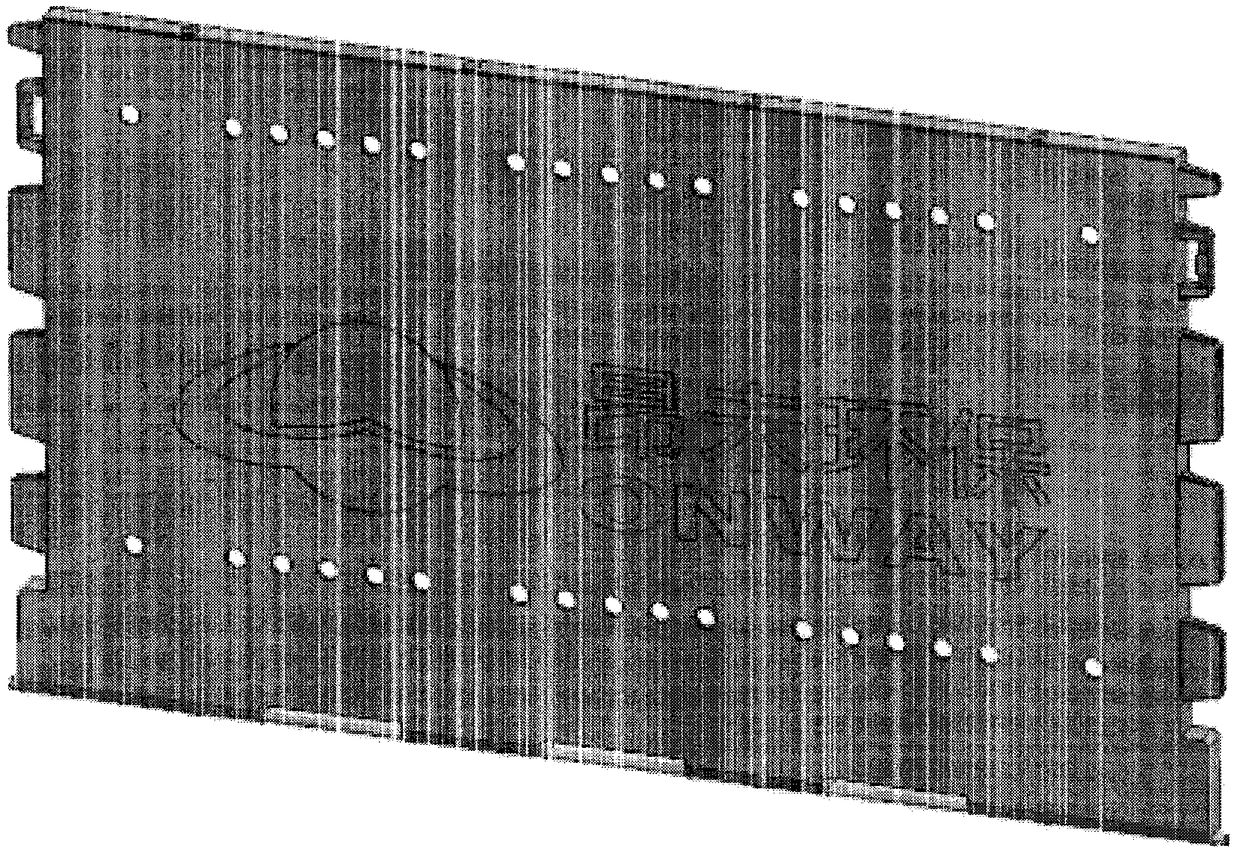

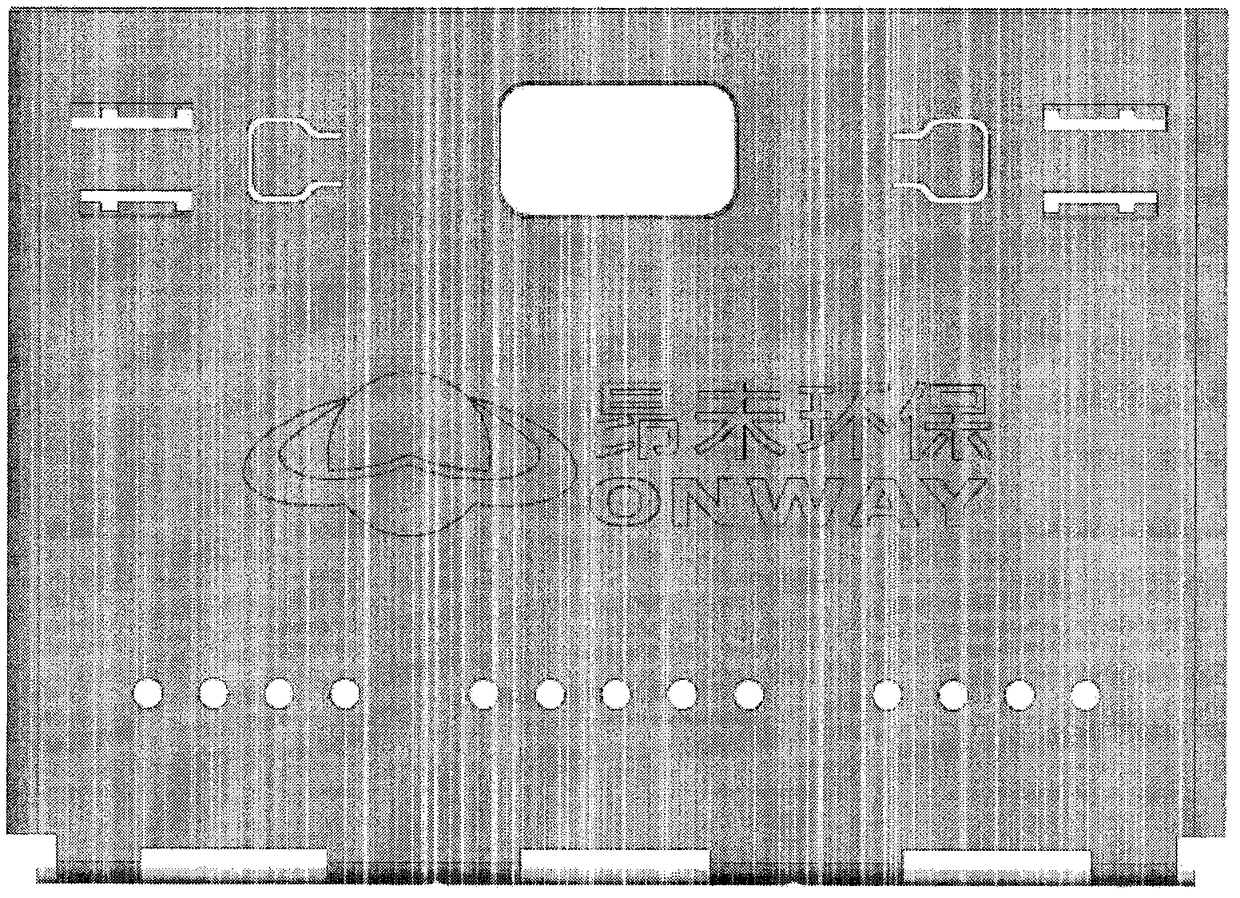

[0014] as follows Figure 1 to Figure 3 shown, a folded packing frame including a base plate figure 1 and long side panels that can be rotated and folded relative to the bottom panel figure 2 , the folded short side panels can be rotated relative to the bottom panel image 3 , There is a hinge connection between the long and short side panels and the bottom panel, the long side panels and the short side panels can be rotated and folded relative to the bottom panel, the frame is flat without protrusions after folding, and the occupied volume is greatly reduced. Figure 4 For snaps, there are guide slots for snaps on the short side panels Figure 5 -⑥, along the guide groove of the clip, the clip can easily connect the long side panel and the short side panel such as Figure 5 -①. Figure 5 -② is the handle hole on the short side panel, which is easy to carry and use. When the filler frame is required, the long side panel and the short side panel are unfolded, the long sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap