Improved stubble-land zero-tillage straw-covering precision planter

A seeder and straw-covering technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problem that the first frame 101 and the second frame 102 are prone to loosening, which affects the overall device operation and increases the maintenance cost of the device and other problems, to achieve the effect of improving operation efficiency, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

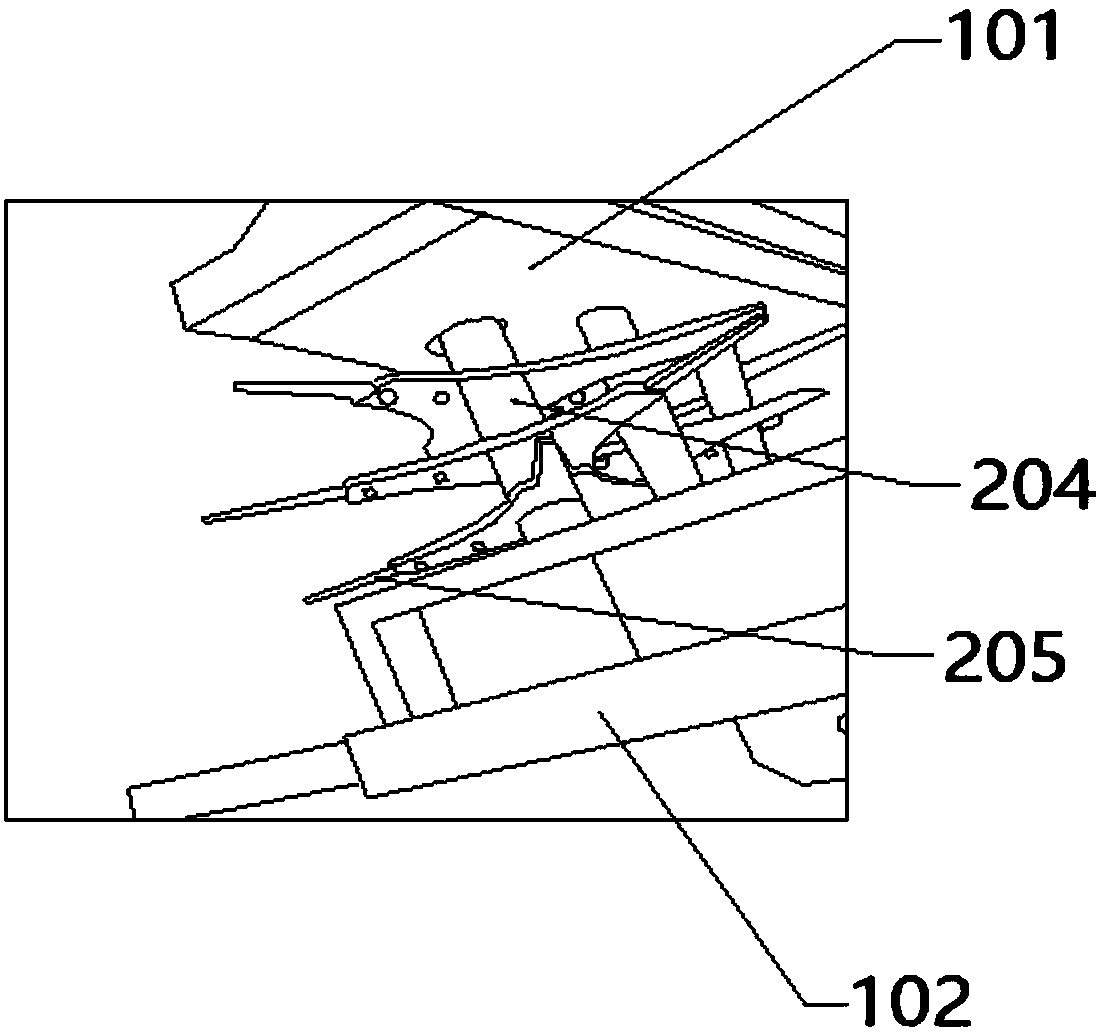

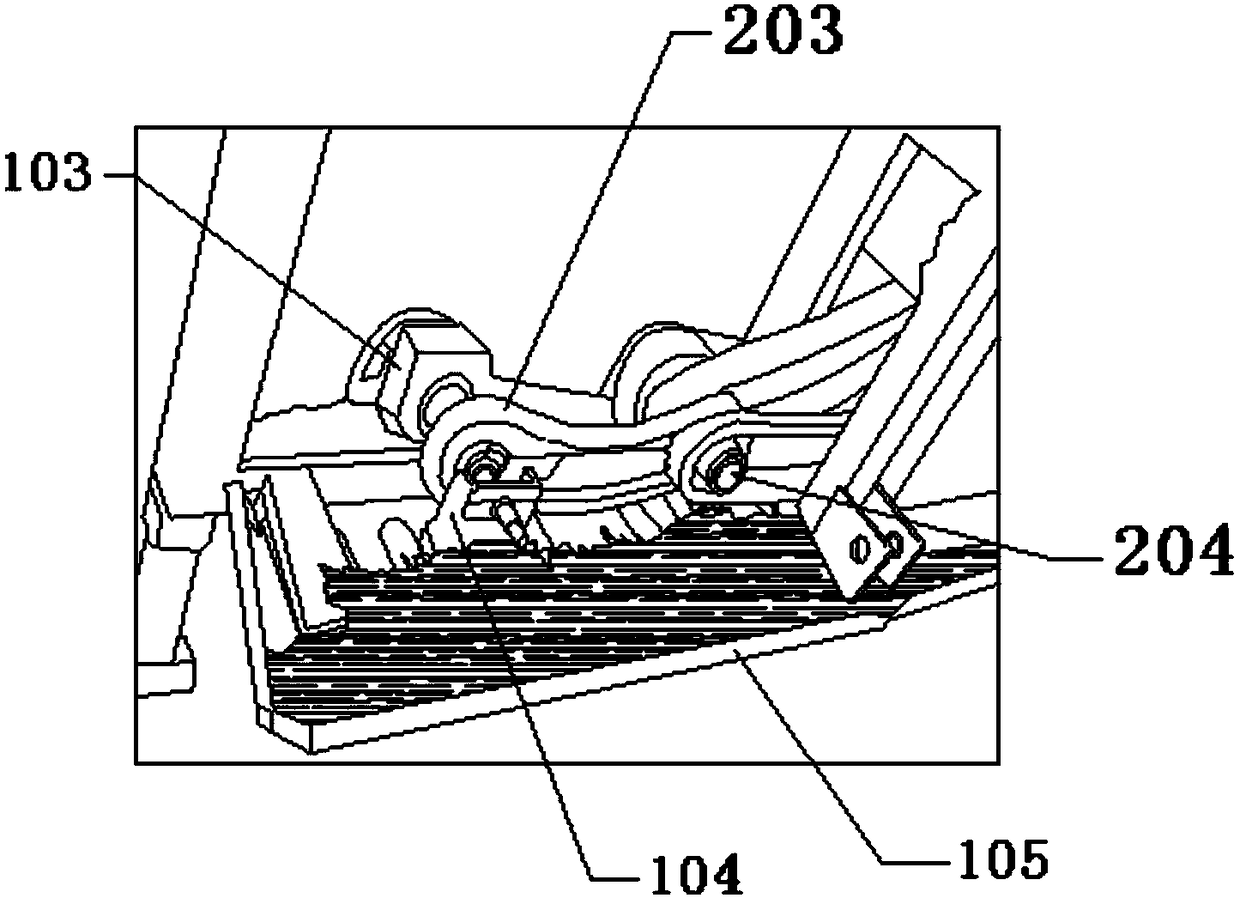

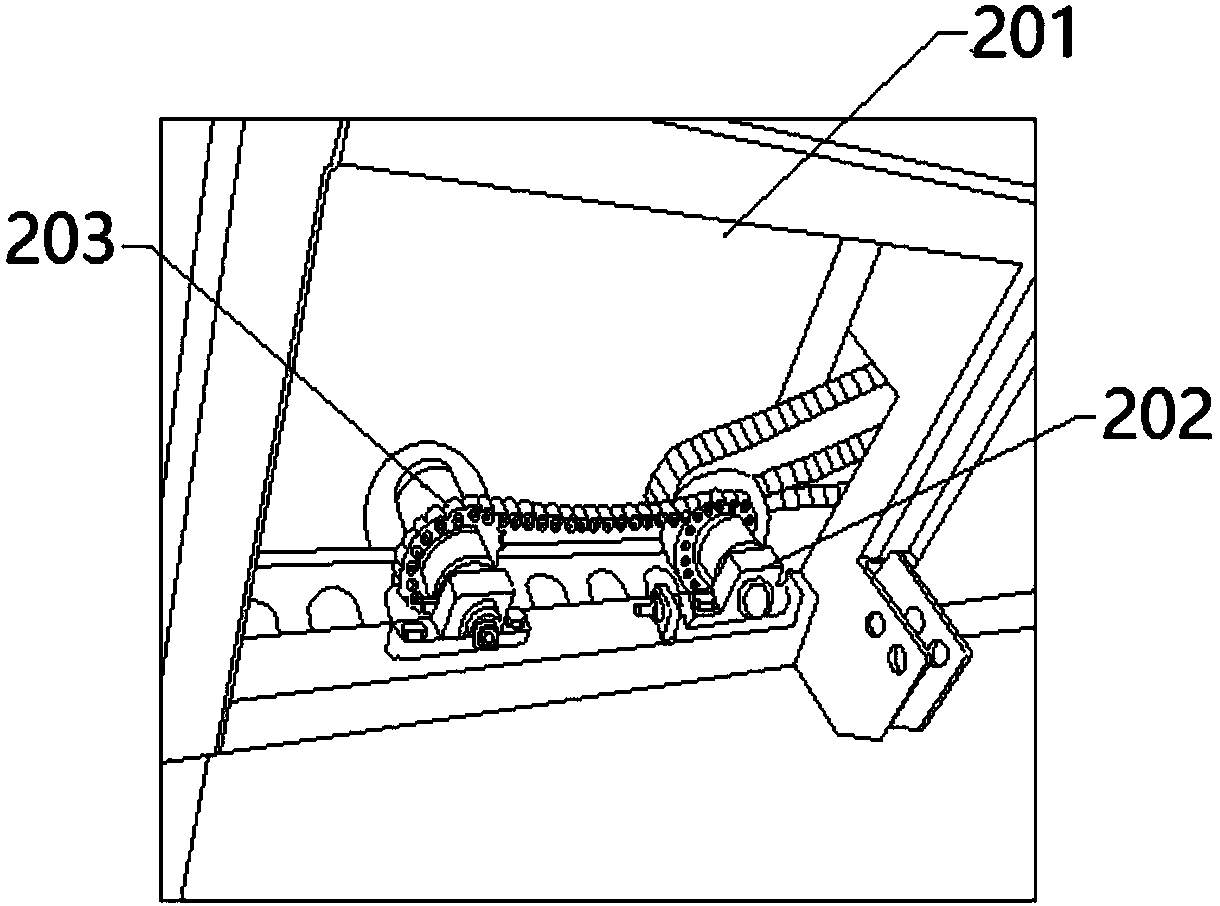

[0027] For the improved no-tillage and straw-covered precision seeder of the present embodiment, please refer to figure 1 , figure 2 with image 3 As shown, it comprises a straw clearing device assembly, and the straw clearing device assembly is vertically arranged on the bottom beam of the frame by 6 straw clearing knife shafts 204, and a bearing is arranged in the described straw clearing knife shaft 204, and a bearing is arranged on it The cutter head, and the end of the straw clearing knife shaft 204 protruding from the frame is sequentially provided with a first fixing structure 103 for fixing the screw rod and a second fixing structure for fixing the end of the straw clearing knife shaft 204 from inside to outside. Structural member, the straw clearing cutter shaft 204 between the first fixed structural member and the second fixed structural member 104 is provided with a chain, the first fixed structural member 103 is a prism with a hollow structure, and the second fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com