Drainage system of dishwasher

A drainage system and drainage pipe technology, which is applied to the washing machine/washing machine for tableware, the parts of the washing machine/rinsing washing machine for tableware, cleaning equipment, etc. , high efficiency, large flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

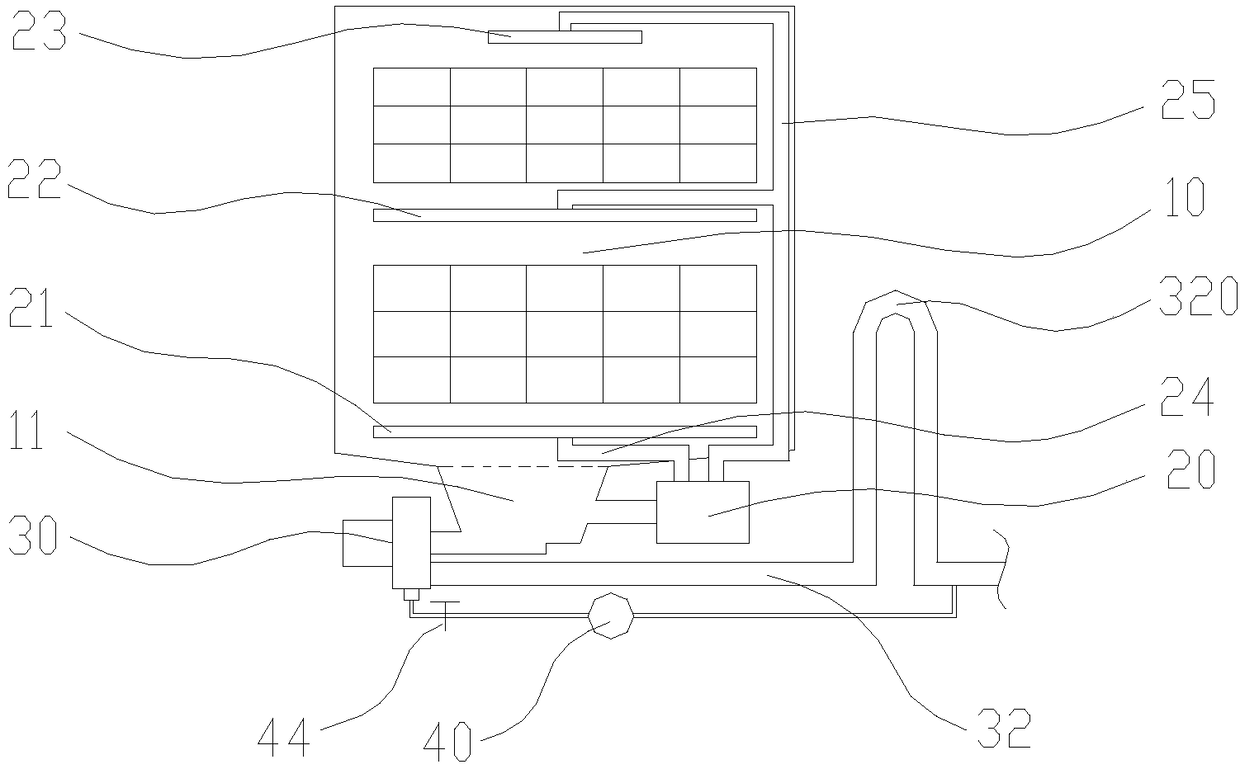

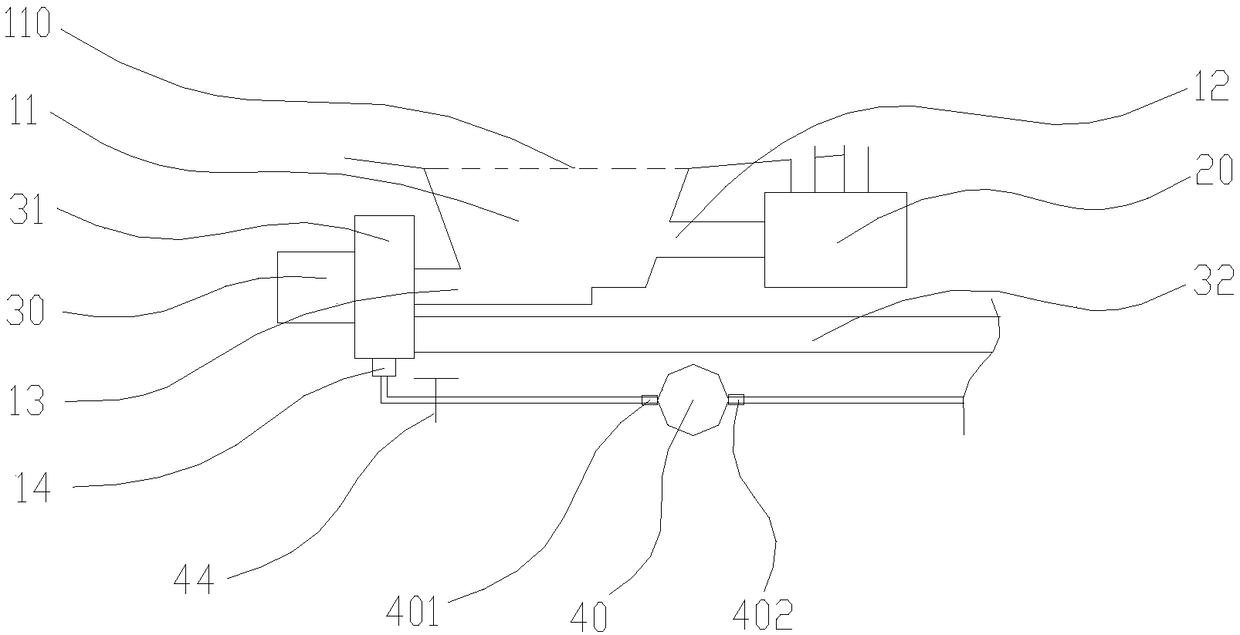

[0024] Figure 1 to Figure 2 Embodiment 1 provided by the present invention provides a pull-down door type dishwasher, which has a washing chamber 10, and a water cup 11 is provided at the bottom of the washing chamber 10, and the upper opening of the water cup 11 is connected to the washing chamber 10 to form a depression. shaped structure or funnel to gather water. The dashed line in the figure represents the filtration system 110 .

[0025] In this embodiment, there is a water suction port 12 at the lower part of the side wall of the water cup 11, which is connected to the circulating water pump 20, and the circulating water pump 20 delivers water to the lower spray arm 21, the middle spray arm 22 and the spray arm 22 through the inner water pipes 24 and 25. Top spray arm 23 places, form the spray cleaning to the tableware in the upper and lower floor baskets.

[0026] In this embodiment, the drainage assembly includes a water cup 11, a drainage passage between the water ...

Embodiment 2

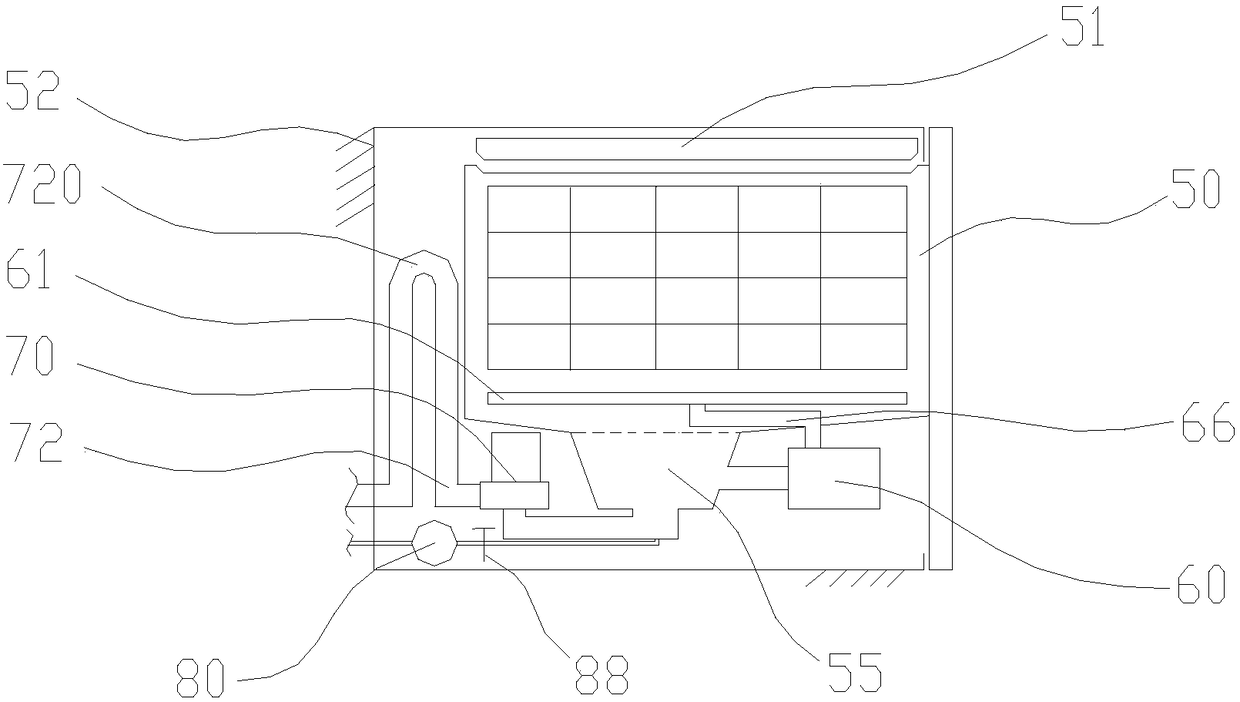

[0033] Figure 3 to Figure 4 Embodiment 2 provided by the present invention, the dishwasher provided in this embodiment is a drawer type dishwasher, which includes a drawer 50 with an upper opening, a cover plate 51 and a housing 52 capable of moving up and down. A water cup 55 is provided at the bottom of the drawer 50, and the upper opening of the water cup 55 is connected to the inside of the drawer 50 to form a concave structure for gathering water. The dotted line in the figure represents the filtration system 550 .

[0034] In this embodiment, there is a water suction port 56 in the lower part of the side wall of the water cup 55, which is connected to the circulating water pump 60, and the circulating water pump 60 supplies water to the spray arm 61 through the water pipe 66 to form the spray cleaning of the tableware.

[0035] In this embodiment, the drainage assembly includes a water cup 55, which communicates with the drainage channel of the water cup 55 and the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com