Loader bucket wall once molding welding tool

A technology for welding tooling and loaders, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of difficult processing and use, increase mechanical processing procedures, and unstable lifting, and achieve the goal of overcoming welding Low precision, reduced machining process, rapid prototyping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

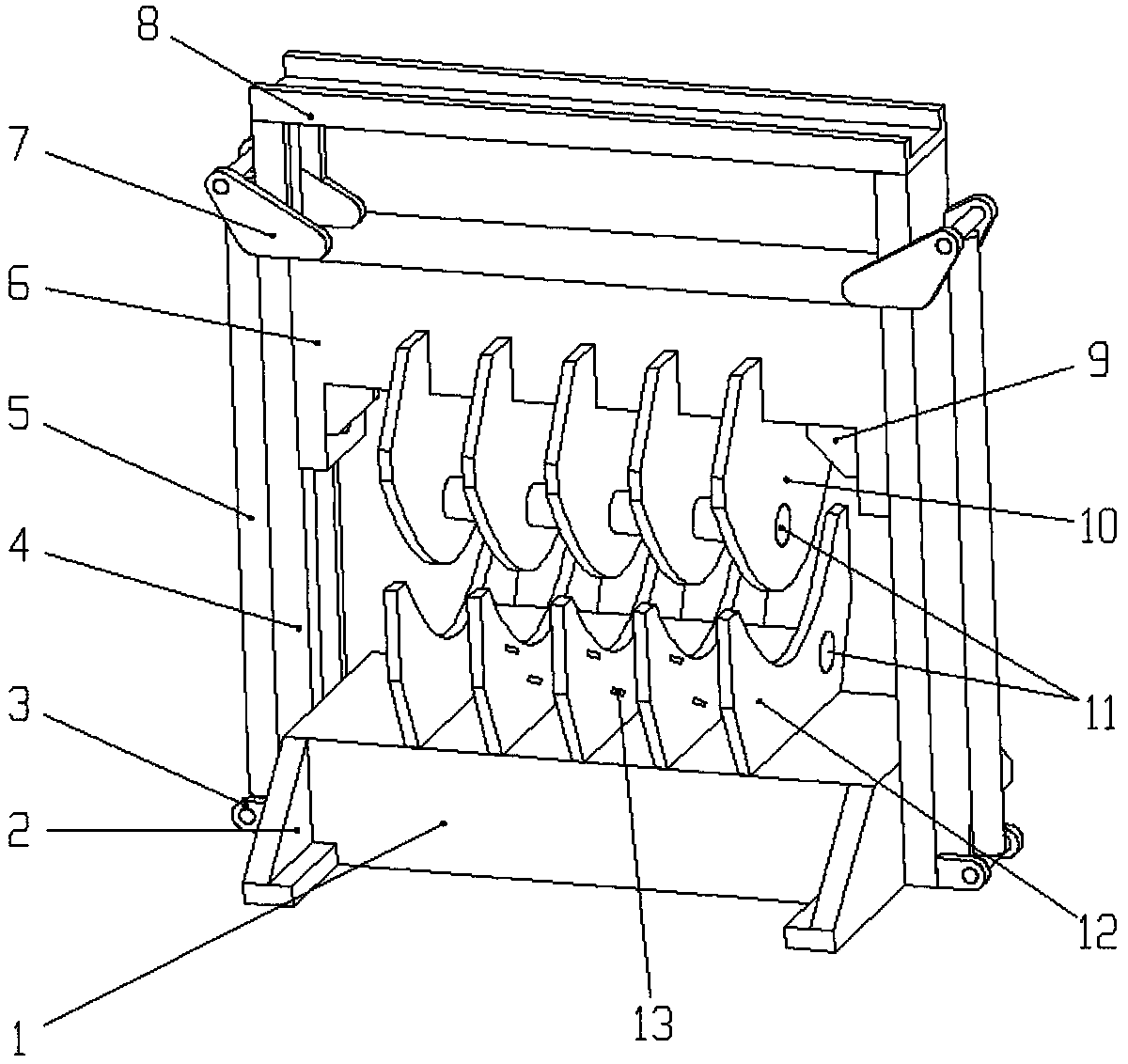

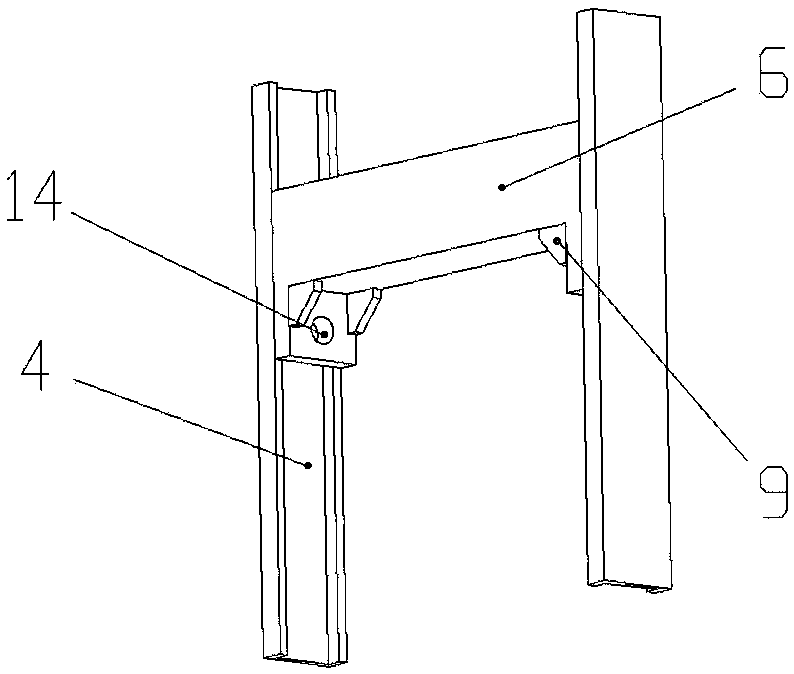

[0015] Such as figure 1 As shown, the one-time forming welding tooling for the loader bucket wall of the present invention includes: a base 1, a column 4, and a lifting platform 6. As a working platform, the base 1 is the most basic part of the forming welding tool, and it is also one of the important parts that affect the working stability of the whole machine. A plurality of pressed plates 12 are fixedly connected to the middle position of the upper surface of the base 1, and the base 1 is surrounded by installations The four base ribs 2 play a role in increasing the overall stability of the tooling.

[0016] The plurality of pressed plates 12 are connected as a whole through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com