A glass edging device for engineering

A glass edging and engineering technology, applied in grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of wasting materials, wasting time and energy, and uneven edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

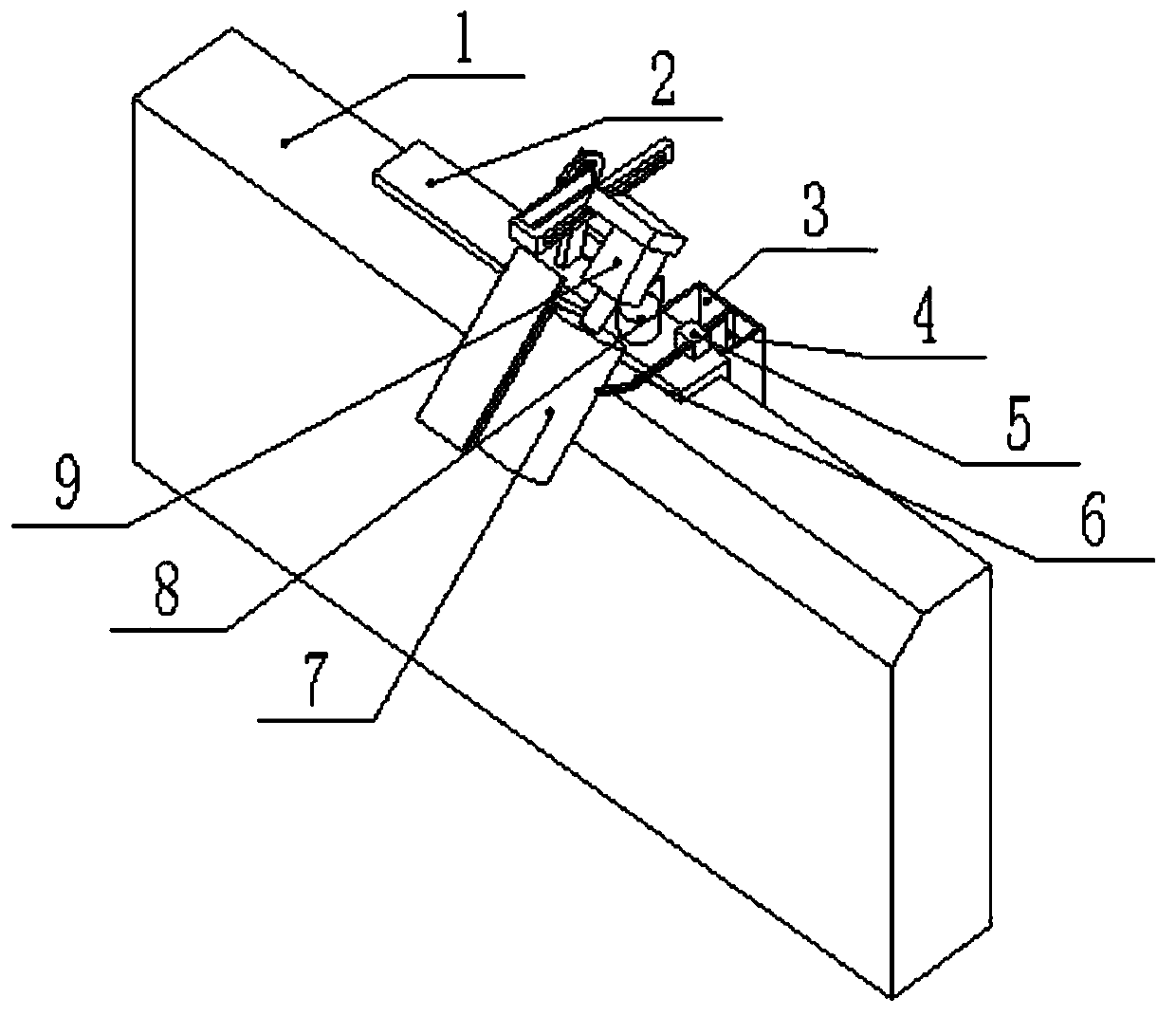

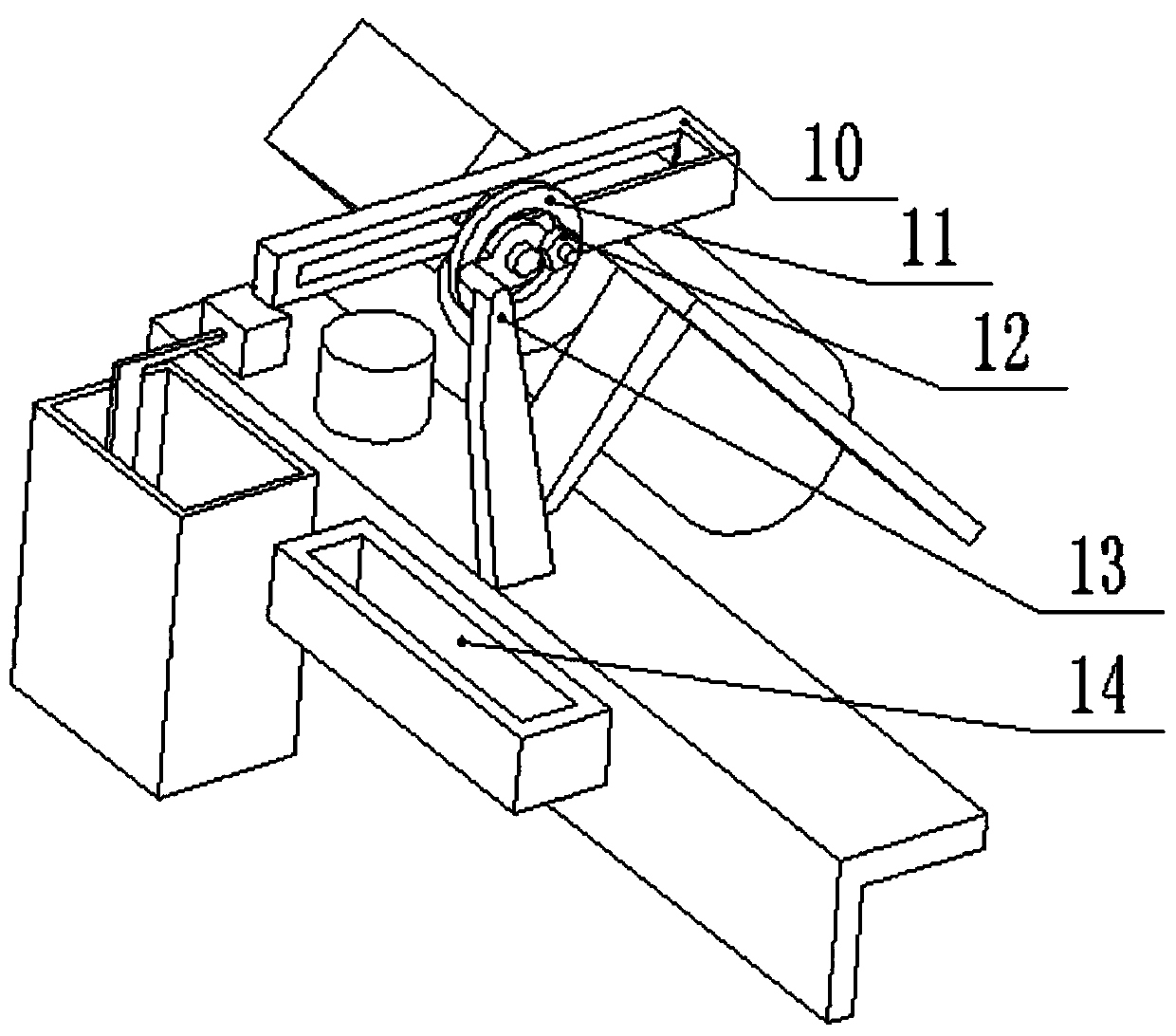

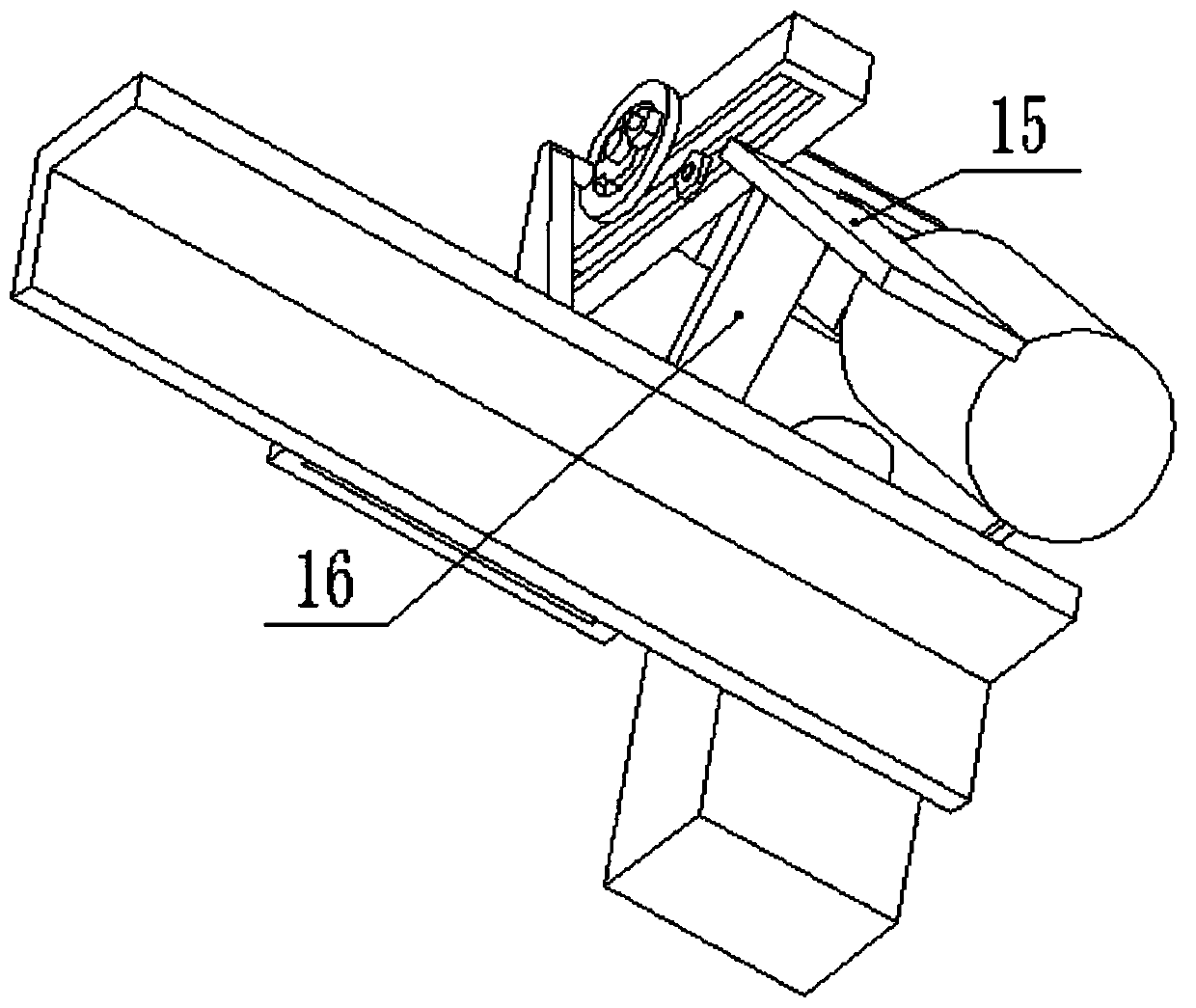

[0016] The present invention is realized through the following technical solutions: an engineering glass 1 edging device, including glass 1, limit bar 2, water tank 3, water inlet pipe 4, water pump 5, water outlet pipe 6, grinding wheel 7, controller 8, motor 9. The first bracket 10, the return ring 11, the first fixing nut 12, the second bracket 13, the hand-held bracket 14, the shielding plate 15, the third bracket 16, the motor base 17 and the second fixing nut 18, the glass 1 is a cube structure, and its side to be edging is vertically fixed on the ground upwards, and the limiting bar 2 is an L-shaped strip with a middle kink angle of 90 degrees, which fits on the opposite side to be edging, It is ensured that there will be no relative offset between the grinding wheel 7 and the glass 1 during the grinding process, so that the edge of the grinding is pitted. The water tank 3 is fixed on the side of the limit bar 2, which is a hollow cube. The water inlet pipe 4 One end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com