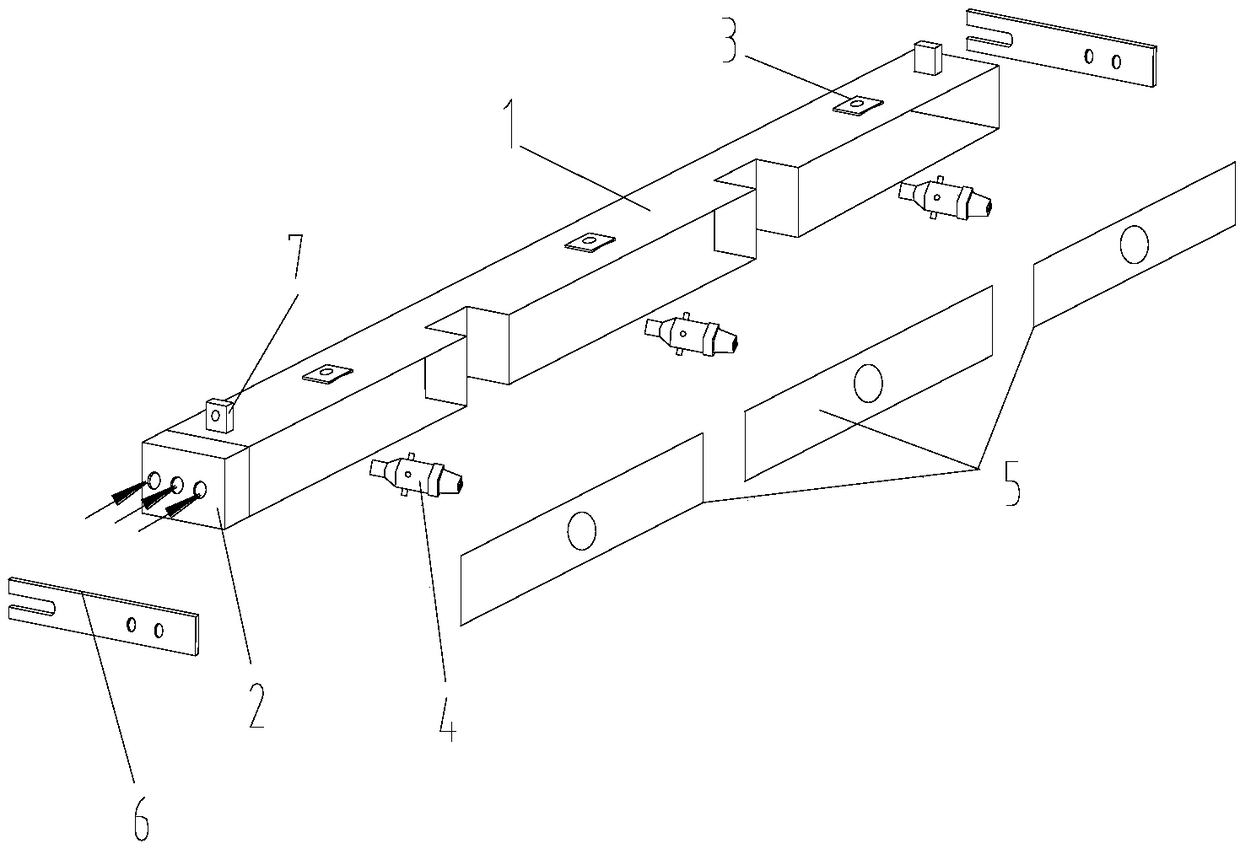

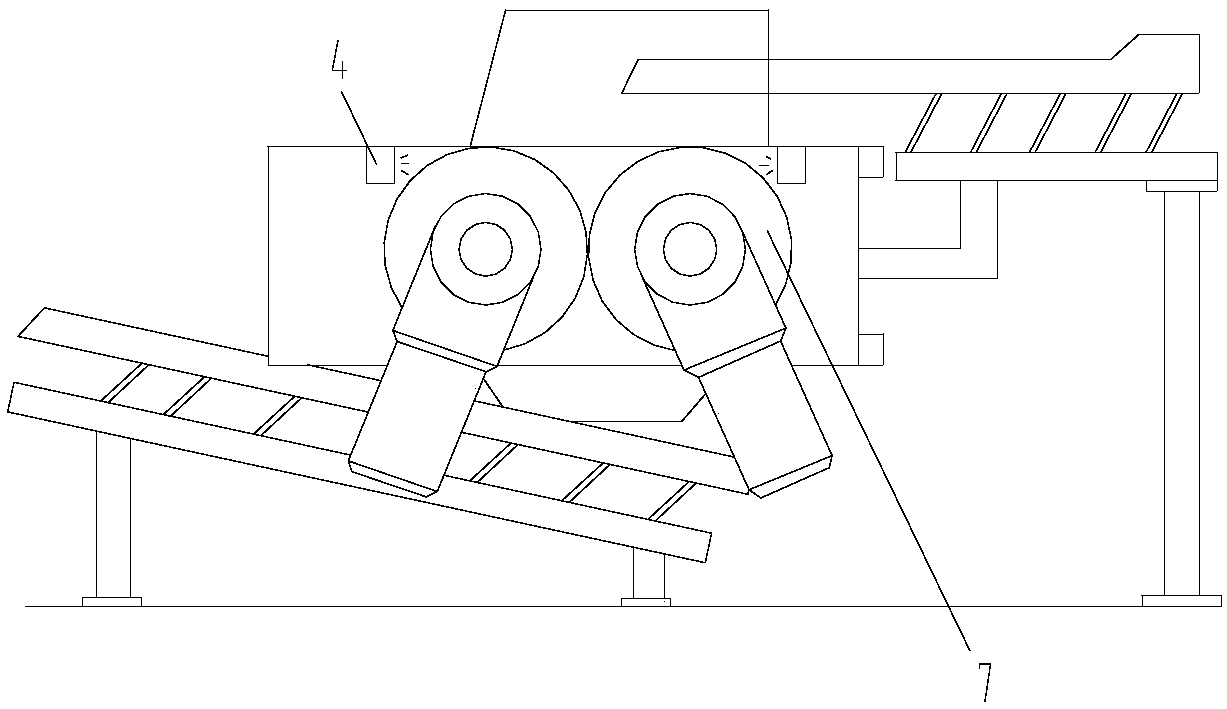

Novel combined nozzle of tobacco stem pressing machine

A technology of stem pressing machine and nozzle, which is applied to conveyors, tobacco, and cigarette manufacturing, etc. It can solve problems such as small gap between pressing rollers, stoppage due to material breaking, and impact on product quality, and achieves the effect of quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In this embodiment, it should be noted that relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply that these entities or operations There is no such actual relationship or order between the operations. Furthermore, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article, or apparatus comprising a set of elements includes not only those elements, but also includes elements not expressly listed. other elements of or also include elements inherent in such a process, method, article, or device.

[0016] In addition, in this specific embodiment, if the connection or fixing method between the components is not specified in particular, the connection or fixing method can be fixed by bolts or pins commonly used in the prior art, or connected by pin shafts, etc. Therefore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com