Curved glass as well as preparation method and application thereof

A technology of curved glass and a manufacturing method, which is applied to glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of increased production cost, high requirements for polishing equipment, unfavorable application of curved glass products, etc., and achieves the goal of reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

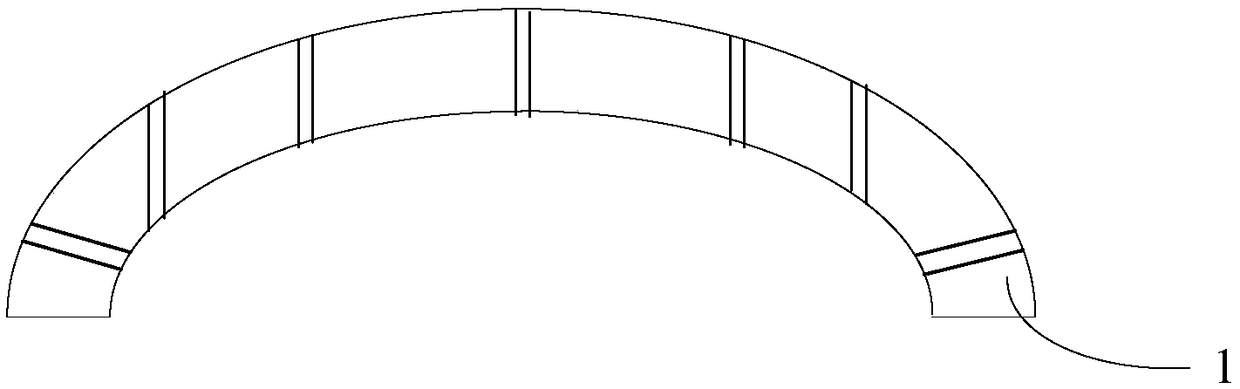

Embodiment 1

[0054] The curved glass of this embodiment is produced by the method for producing curved glass in the above embodiment, wherein the raw glass sheet used is Corning Gorilla Glass III with a thickness of 0.68mm, and the temperature of the first tempering treatment is 420°C. The time is 1h, the temperature of the second tempering treatment is 420°C, the time is 2h, and the radius of the curved surface is 2700mm. The stress layer depth (DOL, unit μm) and stress (CS, unit Mpa) of the curved glass obtained in this embodiment were tested, and the test results are shown in Table 1 below:

[0055] Table 1

[0056]

Embodiment 2

[0058] The curved glass of this example is produced by the method for producing curved glass in the above embodiment, wherein the raw glass sheet used is Corning Gorilla third-generation glass raw material with a thickness of 0.68mm, and the temperature of the first tempering treatment is 420°C , the time is 1.5h, the temperature of the second tempering treatment is 420°C, the time is 1.5h, and the radius of the curved surface is 2160mm. The stress layer depth (DOL, unit μm) and stress (CS, unit Mpa) of the curved glass obtained in this embodiment were tested, and the test results are shown in Table 2 below:

[0059] Table 2

[0060]

Embodiment 3

[0062] The curved glass of this embodiment is produced by the method for producing curved glass in the above embodiment, wherein the raw glass sheet used is CSG white glass raw material with a thickness of 0.33mm, the temperature of the first tempering treatment is 420°C, and the time is 1.5h, the temperature of the second tempering treatment is 420°C, the time is 1.5h, and the radius of the curved surface is 1846mm. The stress layer depth (DOL, unit μm) and stress (CS, unit Mpa) of the curved glass obtained in this embodiment were tested, and the test results are shown in Table 3 below:

[0063] table 3

[0064]

[0065]

[0066] The curved glass produced in Example 1, Example 2, and Example 3 all have good elastic recovery force, and have certain elastic deformation and curved surface self-recovery properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com