Anti-wire twisting feeding device for assisting hexagonal net making machine

The technology of a feeding device and a netting machine is applied in the directions of twisting lace looms, textiles and papermaking, knitting, etc. High efficiency and easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

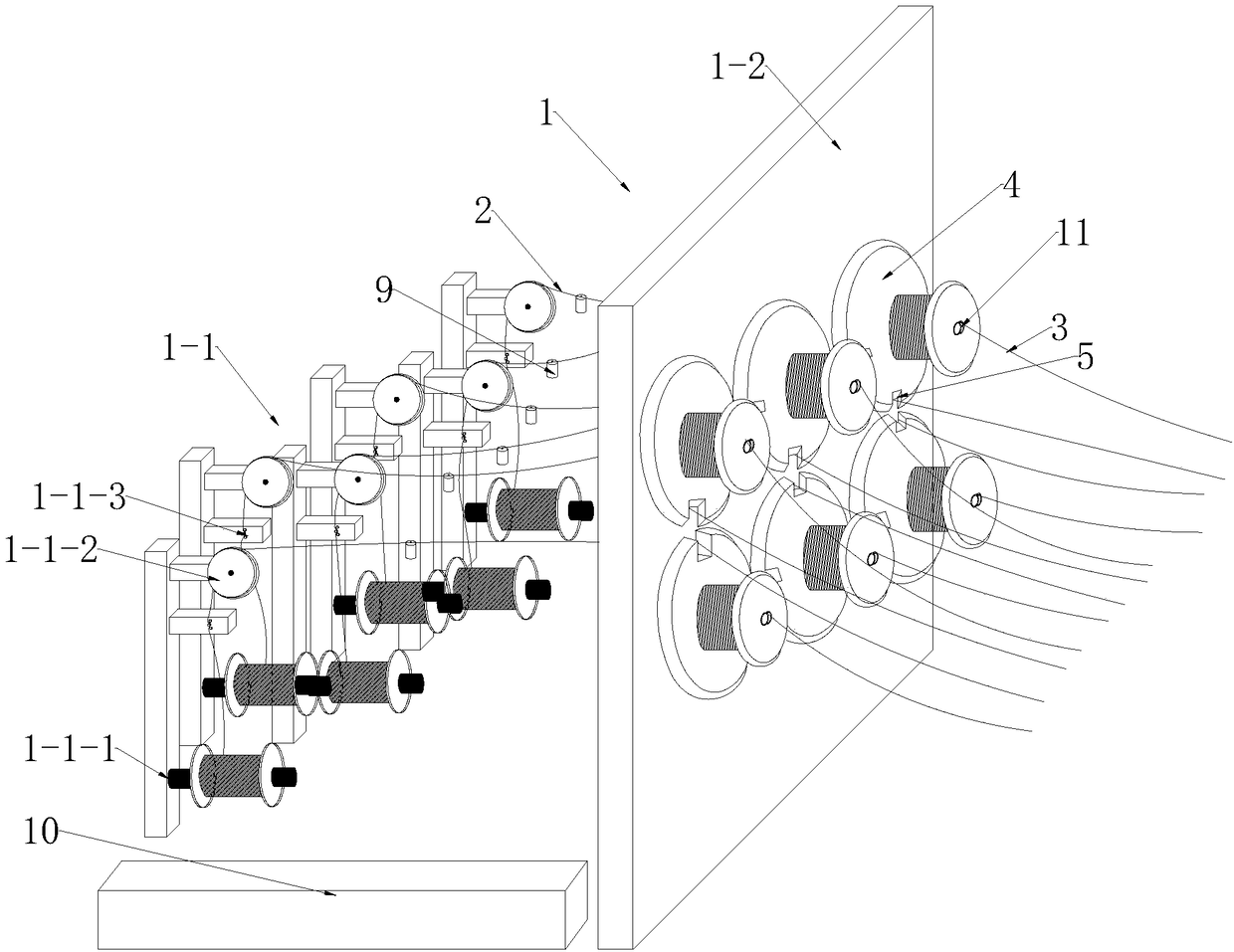

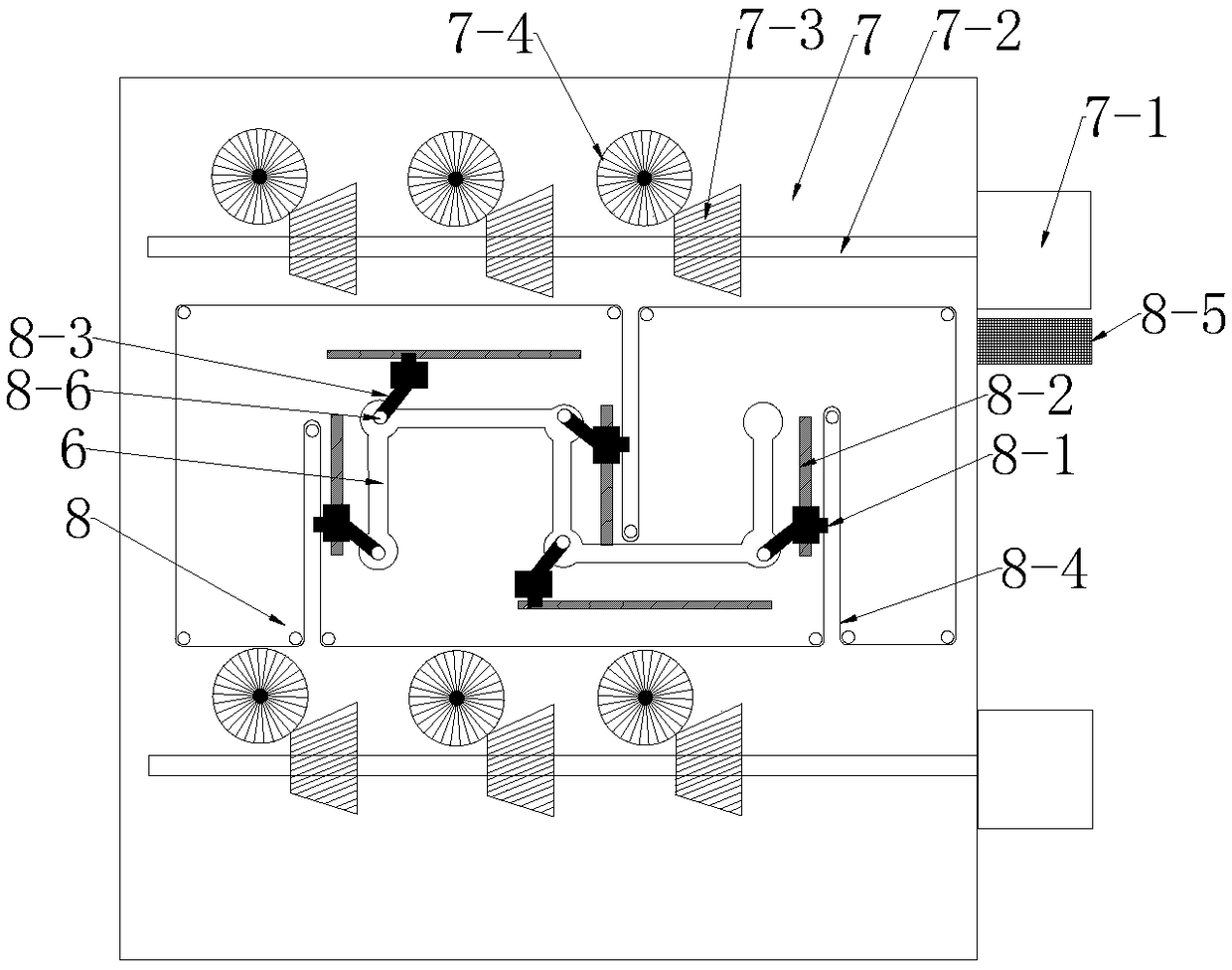

[0013] Such as Figure 1-2 As shown, an anti-twisting wire feeding device for auxiliary hexagonal net making machine includes a wire supply frame 1 for supplying wire materials, and the wire supply frame 1 includes a dynamic wire supply frame for providing dynamic twisted wire 2 1-1 and the static wire supply frame 1-2 that provides the static twisted wire 3, the lower end of the dynamic wire supply frame 1-1 is integrally provided with supporting rollers 1-1-1 from the horizontal direction, and the dynamic twisted wire 2. The wound wire material ring is passed on the support roller 1-1-1. The top of the dynamic wire supply frame 1-1 is connected to the wire transmission wheel 1-1-2 in rotation, and the dynamic wire supply frame 1-1 The middle part of -1 is provided with a straightening wheel set 1-1-3, and the moving twisted wire 2 passes through the straightening wheel set 1-1-3, the wire feeding wheel 1-1-2, The static wire supply frame 1-2 is then transported to the hexag...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap