Corrugated plate carrying and mounting cart with electric wrenches

An electric wrench, installation trolley technology, applied in road safety devices, roads, roads and other directions, can solve the problems of high labor intensity, affecting rust prevention ability, corrugated plate weight, etc., to reduce labor intensity, ensure rust prevention ability, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

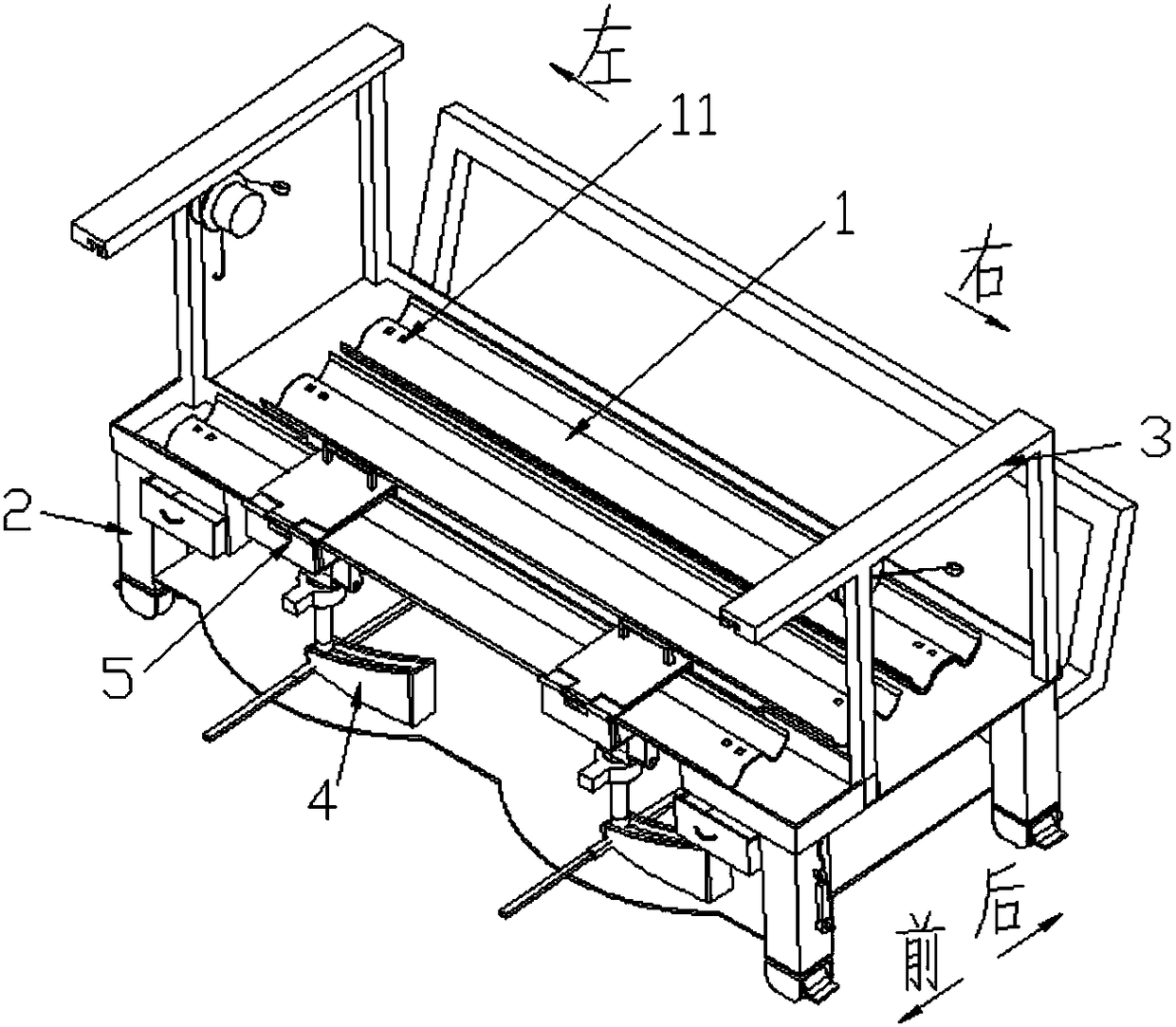

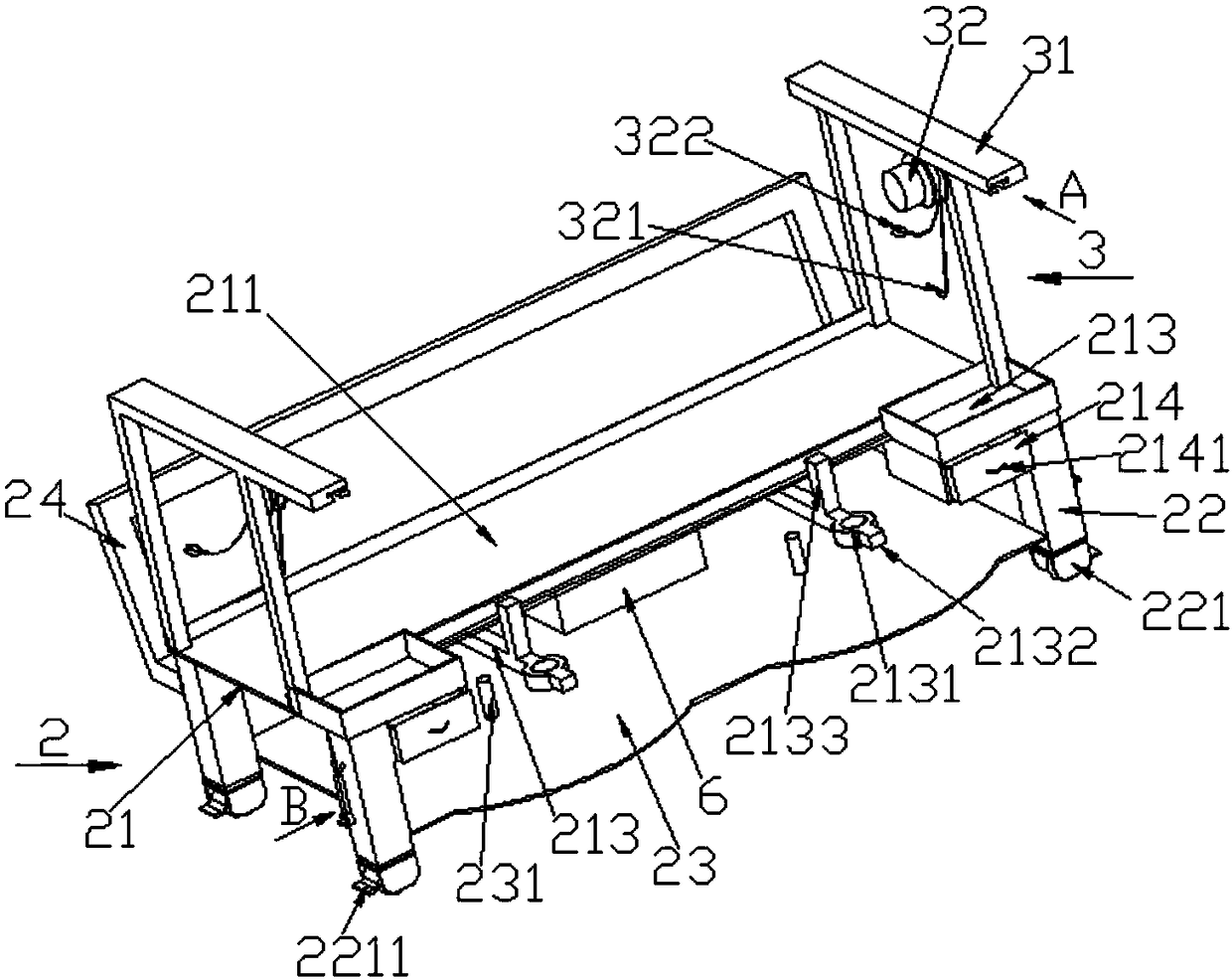

[0042] like Figure 1 to Figure 6 As shown, a corrugated plate handling and installation trolley with an electric wrench includes a corrugated plate 1, a trolley frame 2, a lifting frame 3, an adjustment component 4, a turning component 5, a battery 6, and an electric wrench 7;

[0043] Mounting holes 11 are provided at both ends of the corrugated plate 1;

[0044] The trolley frame 2 includes a shelving platform 21, a supporting foot 22, a mounting plate 23, and a push handle 24;

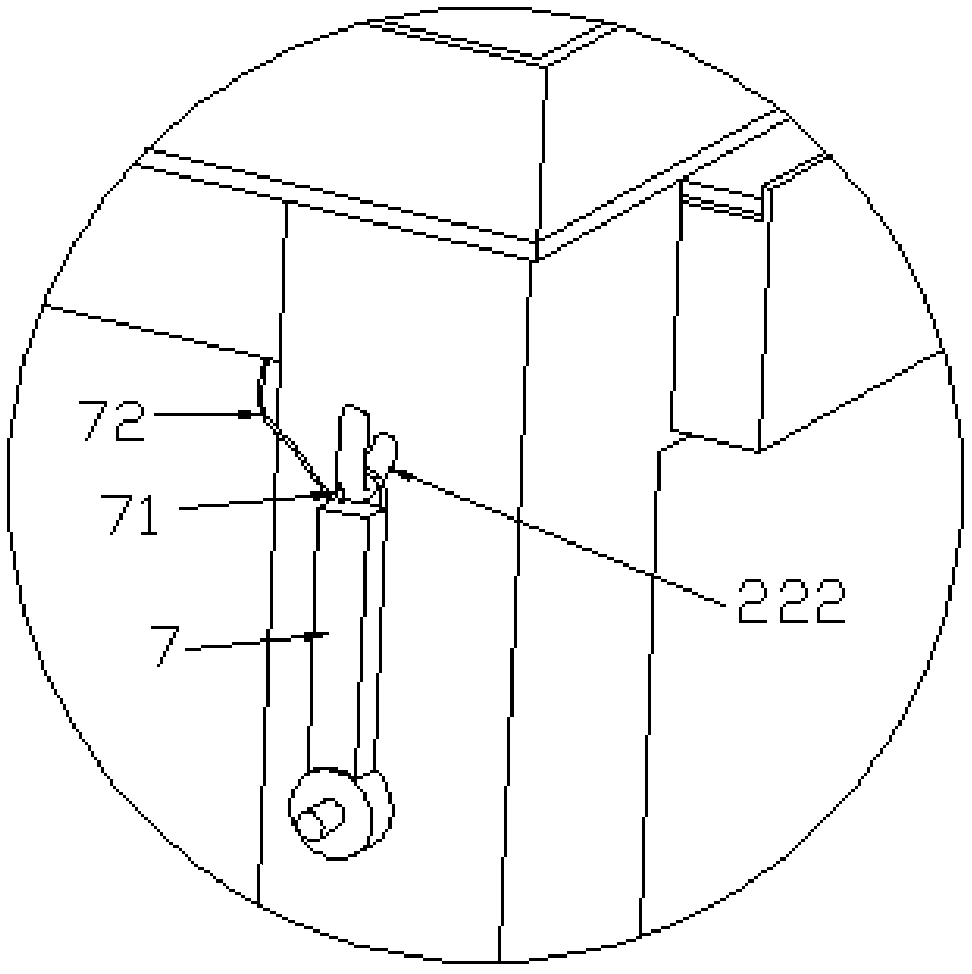

[0045] The supporting feet 22 are arranged at the four corners below the shelving platform 21, and the left and right sides of the front two supporting feet 22 are provided with hooks 222;

[0046] The tail of the electric wrench 7 is provided with a scraper ring 71, and the electric wrench 7 also includes a power connection line 72, and the power connection line 72 is connected to the battery 6;

[0047] The resting platform 21 is "concave" shape, and the "concave" rear part of the resting platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com