Straight-section removal-free concrete template wall and bar penetration mounting construction method thereof

A technology for concrete formwork and concrete slab, which is applied to walls, building components, buildings, etc., can solve the problems of inconvenient operation, discount of building seismic integrity, uneven quality, etc., to improve building assembly rate, reduce labor costs, Guaranteed continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

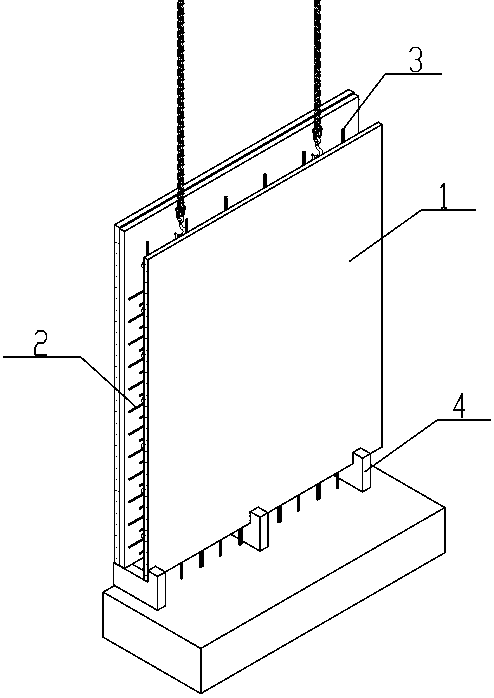

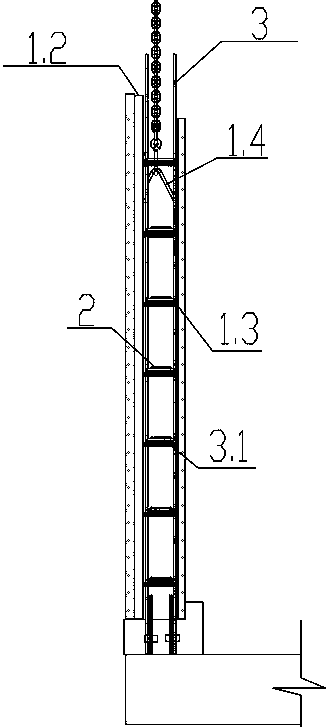

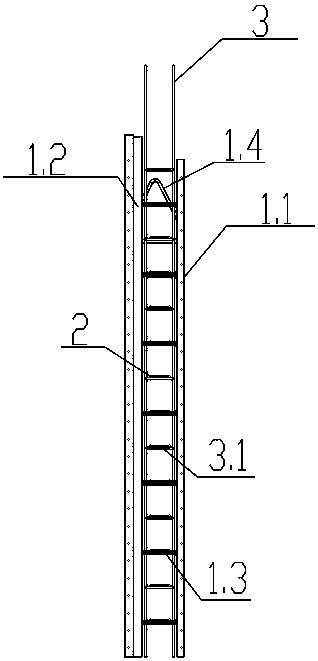

[0040] The following structural drawings describe the present invention in detail:

[0041] A straight section non-demolition concrete formwork wall, the formwork wall includes a straight section non-demolition concrete formwork 1 and vertical reinforcement bars 3 and transverse reinforcement bars 2 inside it;

[0042] The straight segment free concrete formwork 1 includes concrete slabs 1.1 on the inner and outer sides, tie rods 1.3 evenly distributed between the two-layer concrete slabs 1.1 and pre-embedded hangers 1.4;

[0043] The two-layer concrete slabs 1.1 on the inner and outer sides are connected in series through tie rods 1.3,

[0044] The pre-embedded hanger 1.4 is pre-embedded in the concrete slabs 1.1 on both sides.

[0045] The inner side of the outer concrete slab 1.1 is also attached with an insulation board 1.2, the inner and outer concrete slabs 1.1 and the middle insulation board 1.2 are connected in series through a tie rod 1.3, and the pre-embedded hangin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap