Electronic expansion valve

A technology of electronic expansion valve and valve needle, which is applied in the direction of lift valve, valve device, valve details, etc. It can solve the problems of valve port 51' leakage, contact surface wear, and poor valve performance, so as to improve reliability and reduce wear , The effect of reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

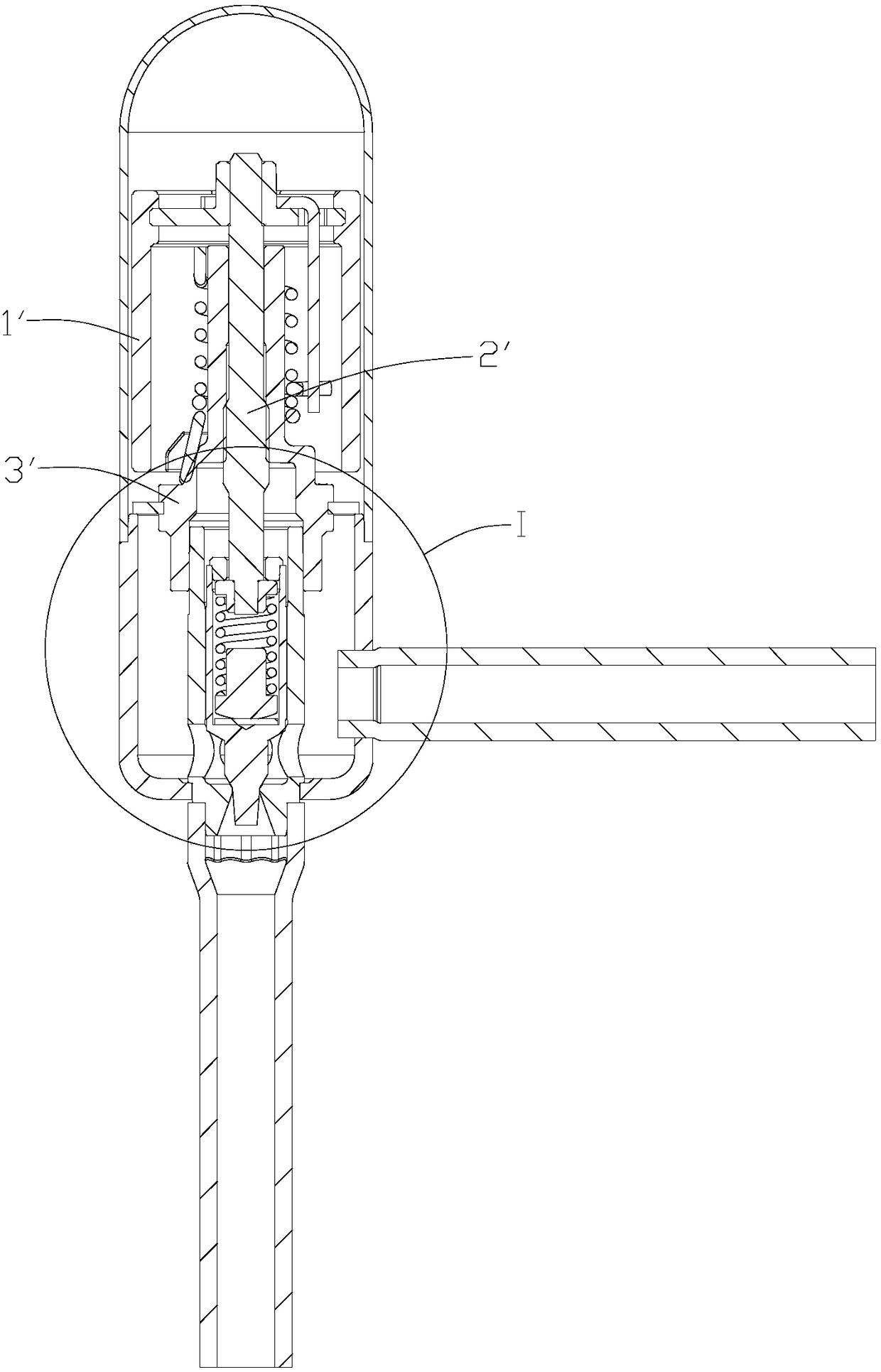

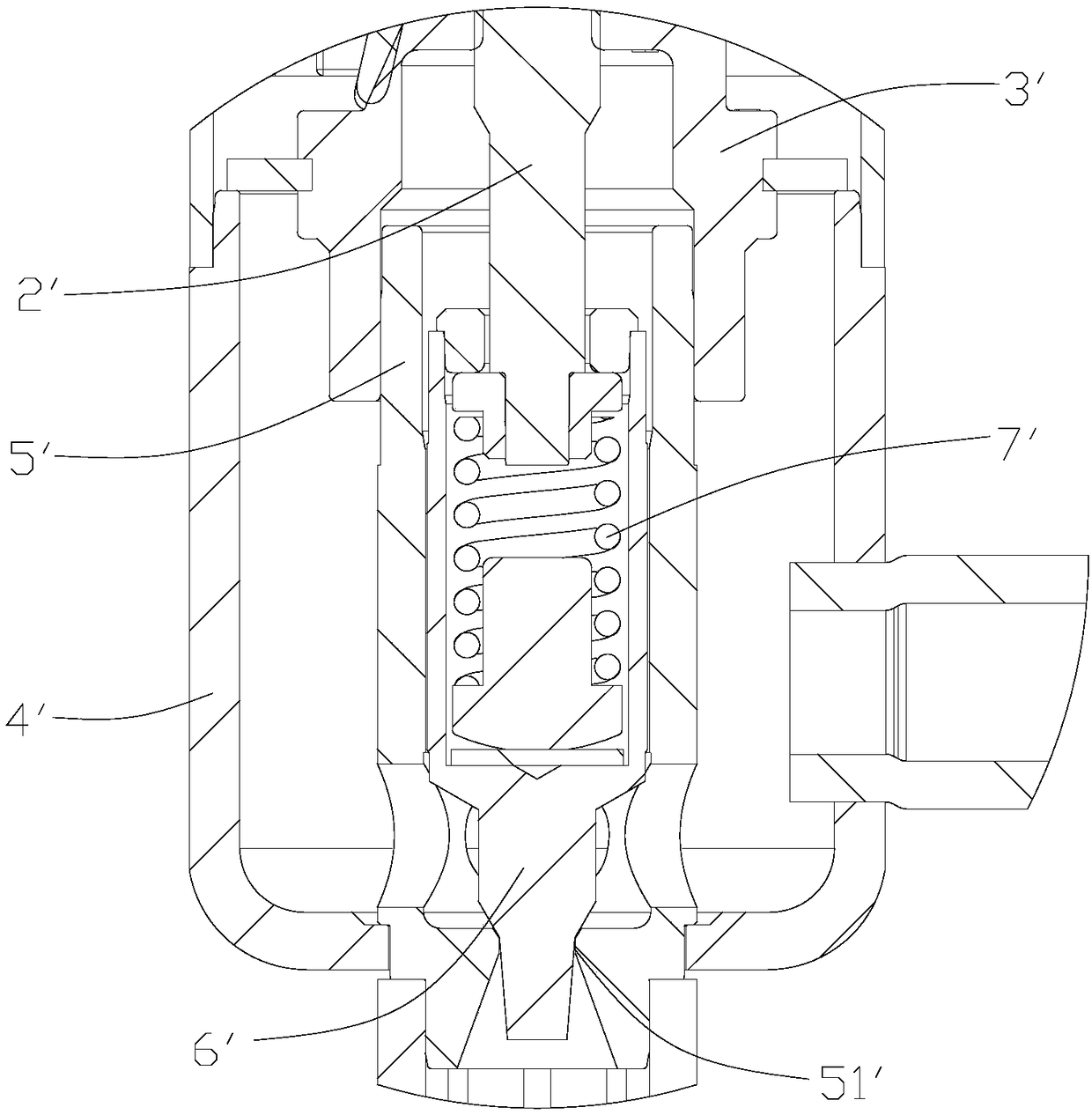

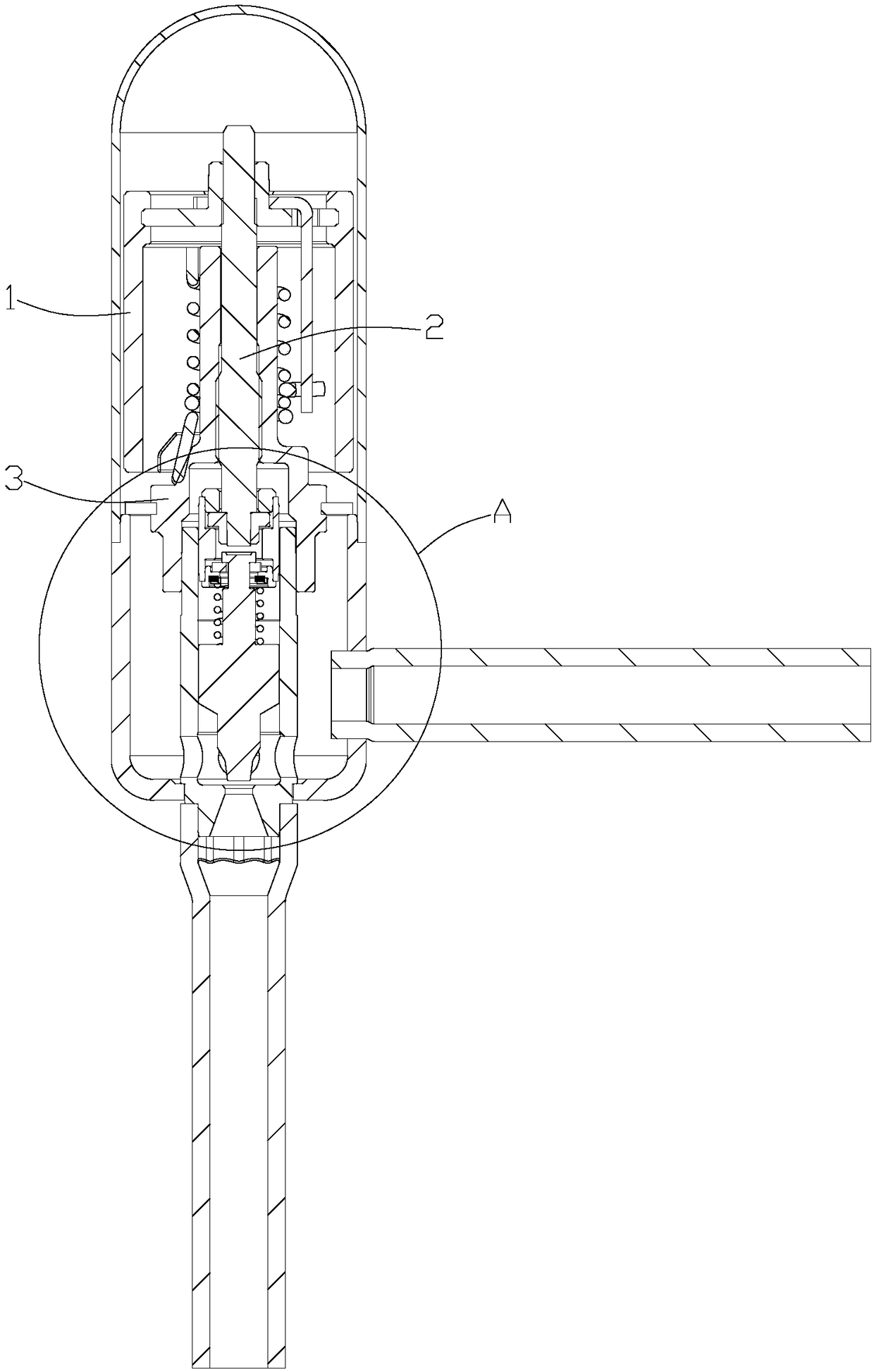

[0114] Please refer to image 3 and Figure 4 , image 3 It is a schematic cross-sectional view of the first embodiment of the electronic expansion valve provided by the present invention; Figure 4 for image 3 Partial enlarged view of part A in the middle.

[0115] in, image 3 The electronic expansion valve is shown open.

[0116] In this embodiment, the rotor 2 of the motor of the electronic expansion valve can rotate and drive the externally threaded shaft 2, and the externally threaded portion of the externally threaded shaft 2 is threadedly engaged with the internally threaded hole of the internally threaded part 3, wherein the internally threaded file 3 is fixed on The upper end of the valve seat 4; the lower end of the externally threaded shaft 2 is also connected with a valve needle 6a.

[0117] When the motor rotates, its rotor 2 can drive the externally threaded shaft 2 to rotate. At the same time, due to the thread engagement between the externally threaded ...

Embodiment 2

[0156] Please refer to Figure 8 and Figure 9 , Figure 8 It is a schematic cross-sectional view of the second embodiment of the electronic expansion valve provided by the present invention; Figure 9 for Figure 8 Partial enlarged view of part B in middle.

[0157] in, Figure 8 The electronic expansion valve is shown open.

[0158] In this embodiment, the externally threaded shaft 2 is connected to the valve needle 6b through a connecting piece 8b.

[0159] Wherein, the upper end of the connecting piece 8b has a first face facing downward, and the lower end of the externally threaded shaft 2 is provided with a first engaging member 9b, and the first engaging member 9b can be engaged with the first face so that the external thread The shaft 2 suspends and supports the connecting piece 8b; in addition, the first engaging piece 9b can also move relative to the connecting piece 8b along the axis direction.

[0160] The lower end of the connecting piece 8b has an upward s...

Embodiment 3

[0193] Please refer to Figure 13 and Figure 14 , Figure 13 It is a schematic cross-sectional view of the third embodiment of the electronic expansion valve provided by the present invention; Figure 14 for Figure 13 Partial enlarged view of part C in middle.

[0194] in, Figure 13 The electronic expansion valve is shown open.

[0195] In this embodiment, the externally threaded shaft 2 is connected to the valve needle 6c through a connecting piece 8c.

[0196] Wherein, the upper end of the connecting piece 8c has a first face facing downward, and the lower end of the externally threaded shaft 2 is provided with a first engaging member 9c, the first engaging member 9c can be engaged with the first face, so that the external thread The shaft 2 is suspended from the support connection 9c.

[0197] The connecting part 8c also has a limiting part located under the first face, and the first engaging part 9c can also move relative to the connecting part 8c along the axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com