Device and method for testing external pressure crushing resistance of pipe

A test device and test tube technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as electrical short circuit, untidy site, and difficulty in measuring the strain of the outer wall of the sample, and achieve high safety and test site Cleanliness, flexibility in specimen type and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

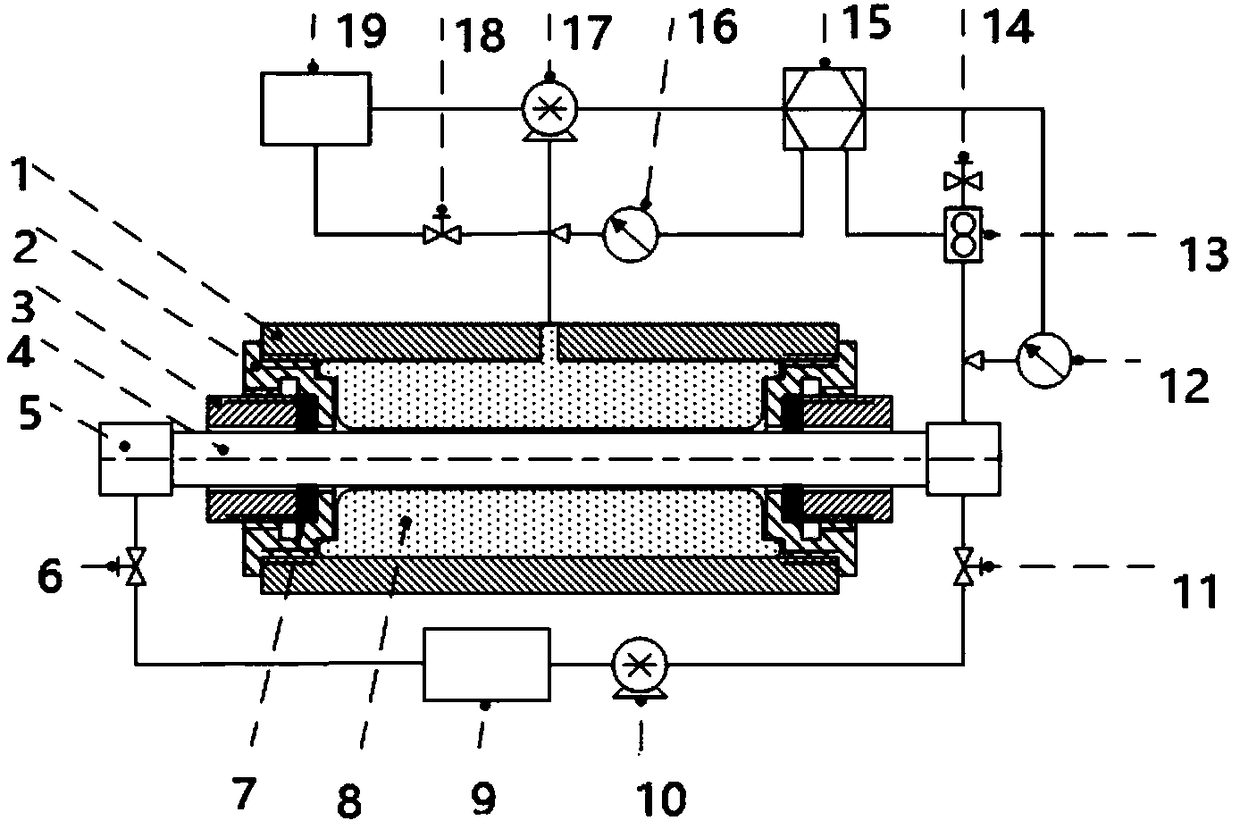

[0031] The present invention is further described below in conjunction with accompanying drawing:

[0032] see figure 1 , a test device for testing the resistance to external pressure crushing of pipes, including a test chamber 1, a pressure capsule 8, a constant temperature device, a pressurizing device, a monitoring device, a sample 4 and a sample holder 5; the test chamber 1 is open at both ends The hollow tubular shape, the pressure capsule 8 is arranged for a week along the inner wall of the test chamber 1, and the middle of the pressure capsule 8 forms a strip-shaped space, the sample 4 is arranged in the strip-shaped space, and the sample holder 5 is arranged at both ends of the sample 4; The constant temperature device is connected to the sample holder 5 , the pressurizing device is connected to the pressure capsule 8 , and the monitoring device is connected to the sample holder 5 .

[0033] The constant temperature device includes a temperature control water tank 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com