Fitting method for membranes and optical membrane set

A diaphragm and underlying film technology, which is applied in the fields of optics, nonlinear optics, chemical instruments and methods, etc., can solve the problem of difficulty in meeting the diaphragm requirements of complex backlight modules, poor stiffness of optical diaphragms, and few types of laminated diaphragms, etc. problems, to achieve the effect of improving reliability, good stiffness, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

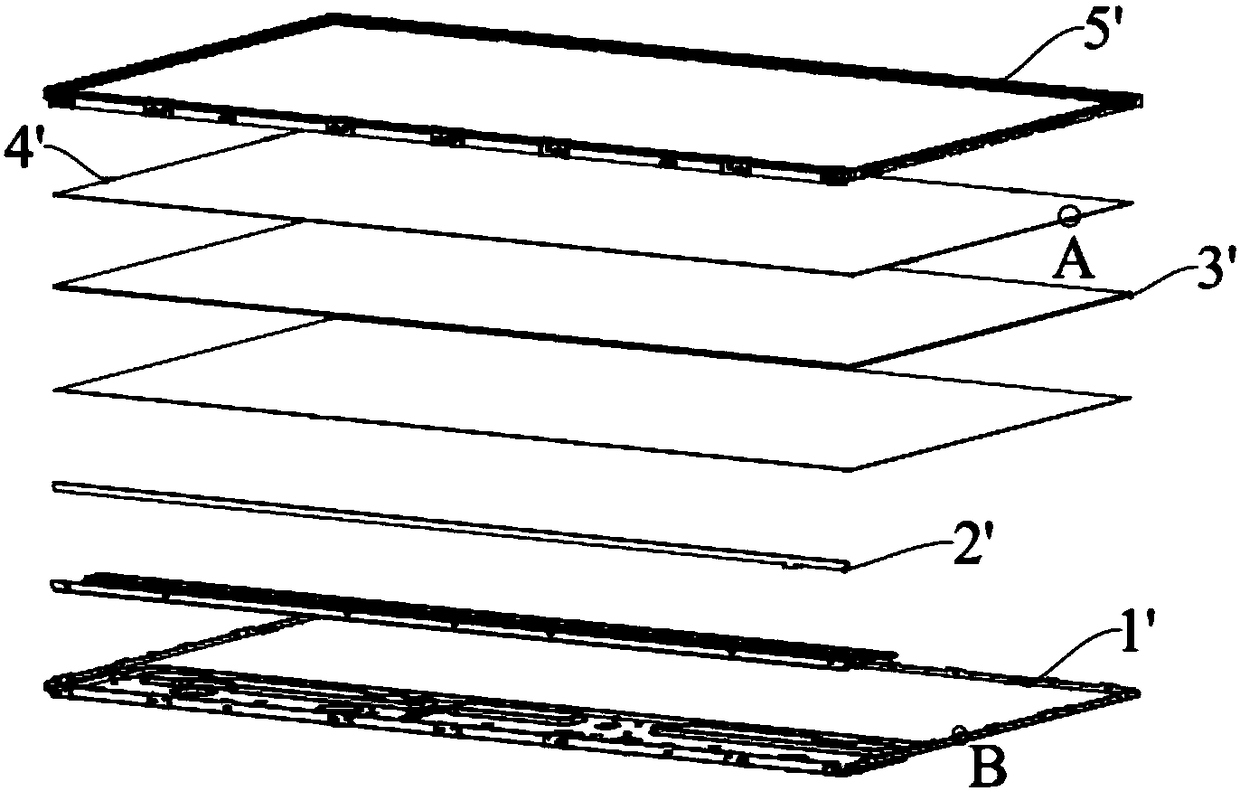

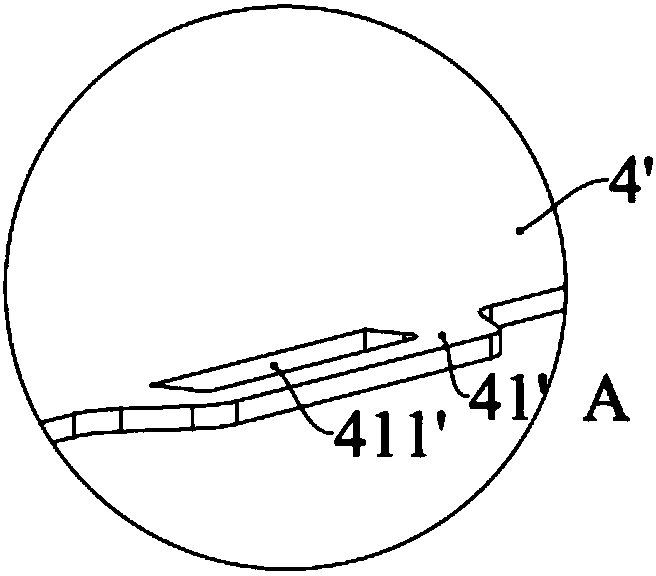

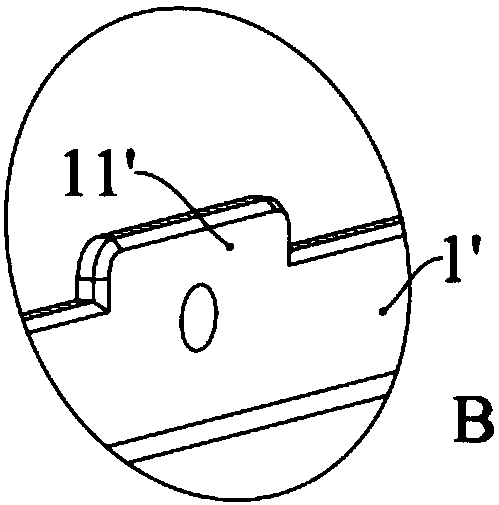

[0040] This embodiment provides a lamination method of the film, which can be used for the optical film in the backlight module, and the optical film is used as an example to introduce below. Such as Figure 4 As shown, before the bonding of the diaphragms 2, a plurality of diaphragms 2 can be arranged sequentially from bottom to top to facilitate bonding. When laminating, place the bottom membrane 2 on the lamination platform 1, and fix the positions of the bottom membrane 2 and the lamination platform 1. Coat the top surface of the lug 21 at the edge of the diaphragm 2 with glue 212, and then stack the diaphragm 2 of the upper layer on the diaphragm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com