Rapid interface device for conveying super-heavy current

An interface device and current technology, which is applied to the parts, coupling devices, circuits and other directions of the connecting device, can solve the problems of troublesome disassembly and assembly, poor contact, large size of the connecting device, etc., to achieve convenient installation and maintenance, improve the current level, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

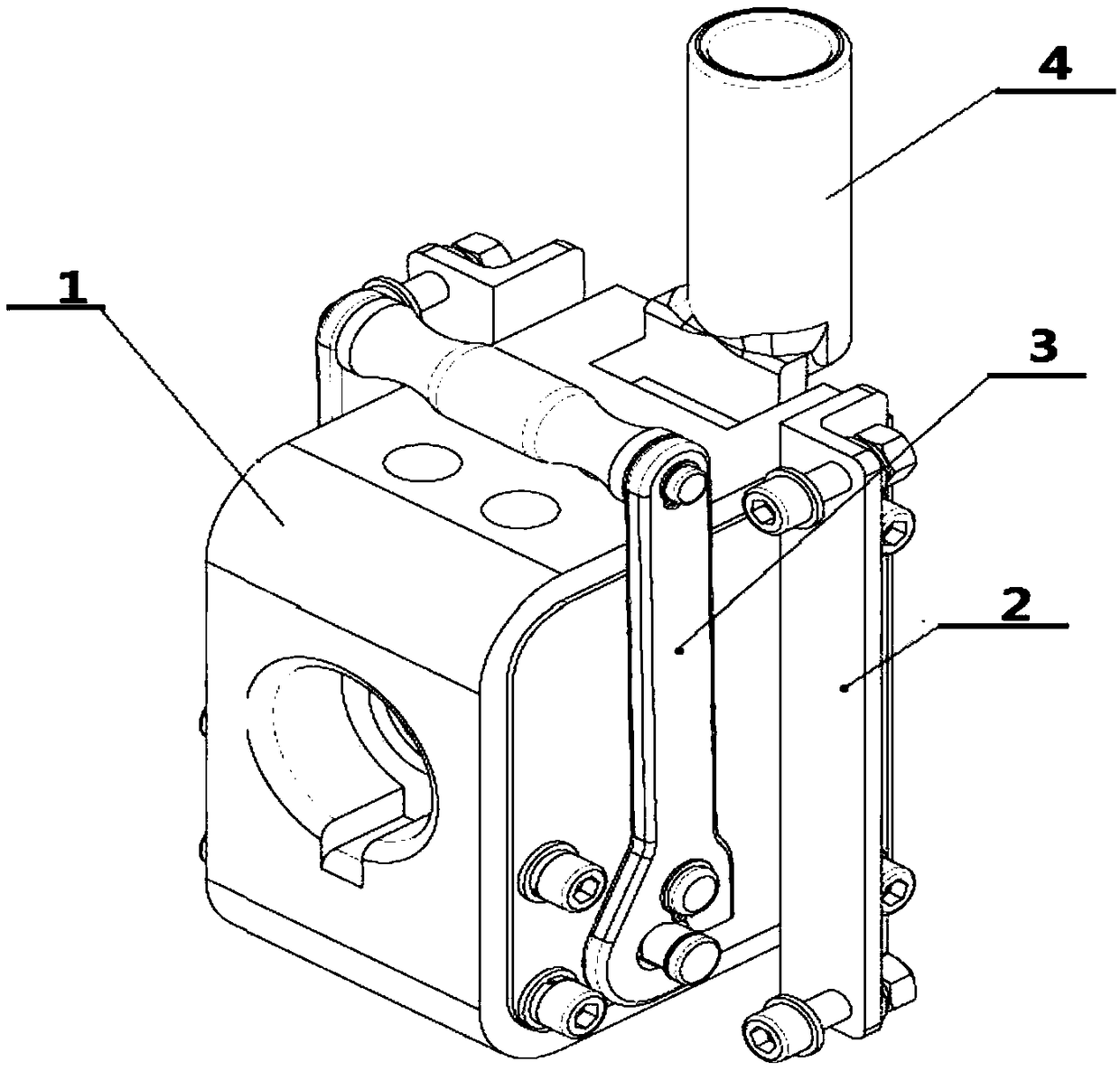

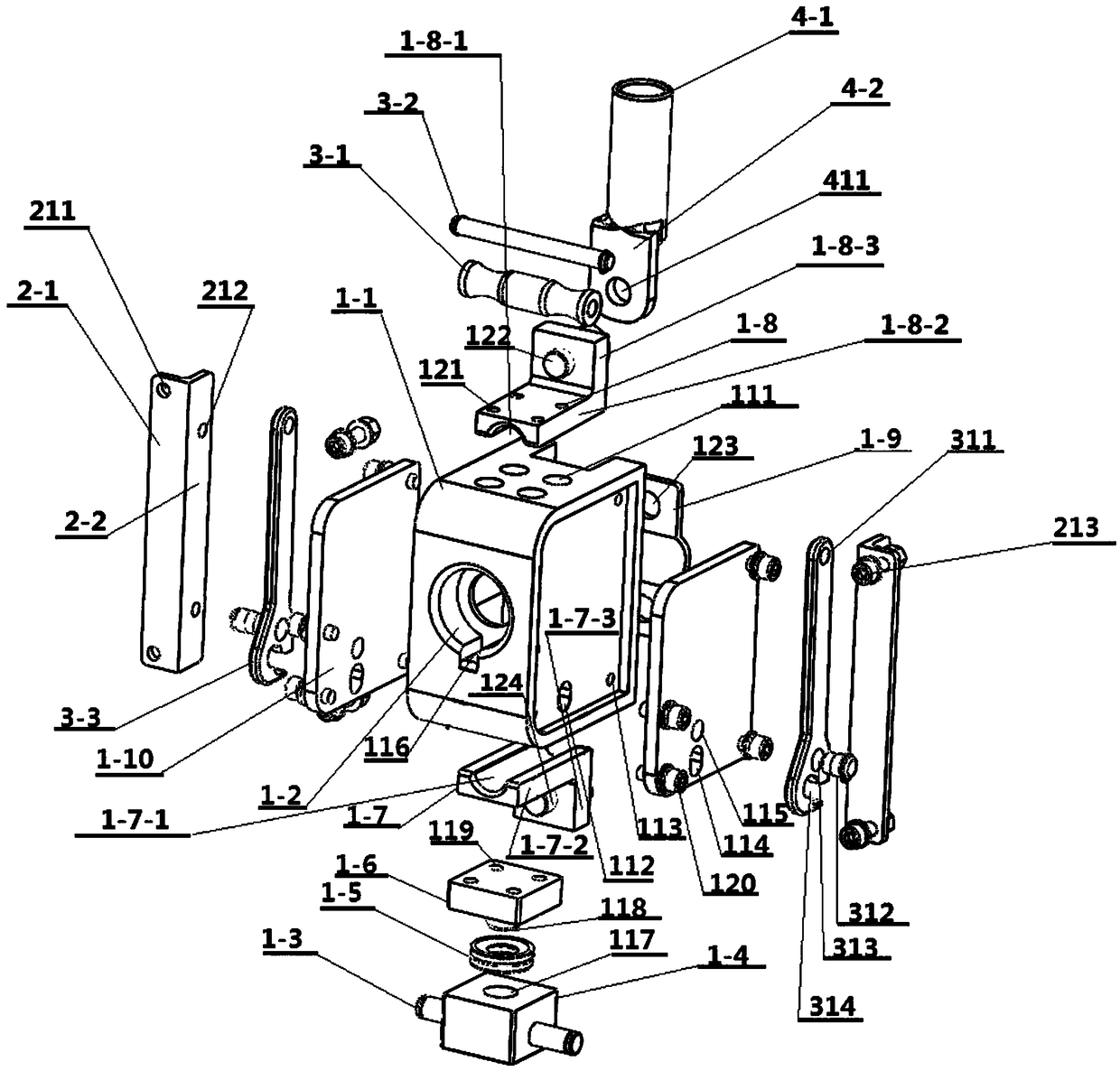

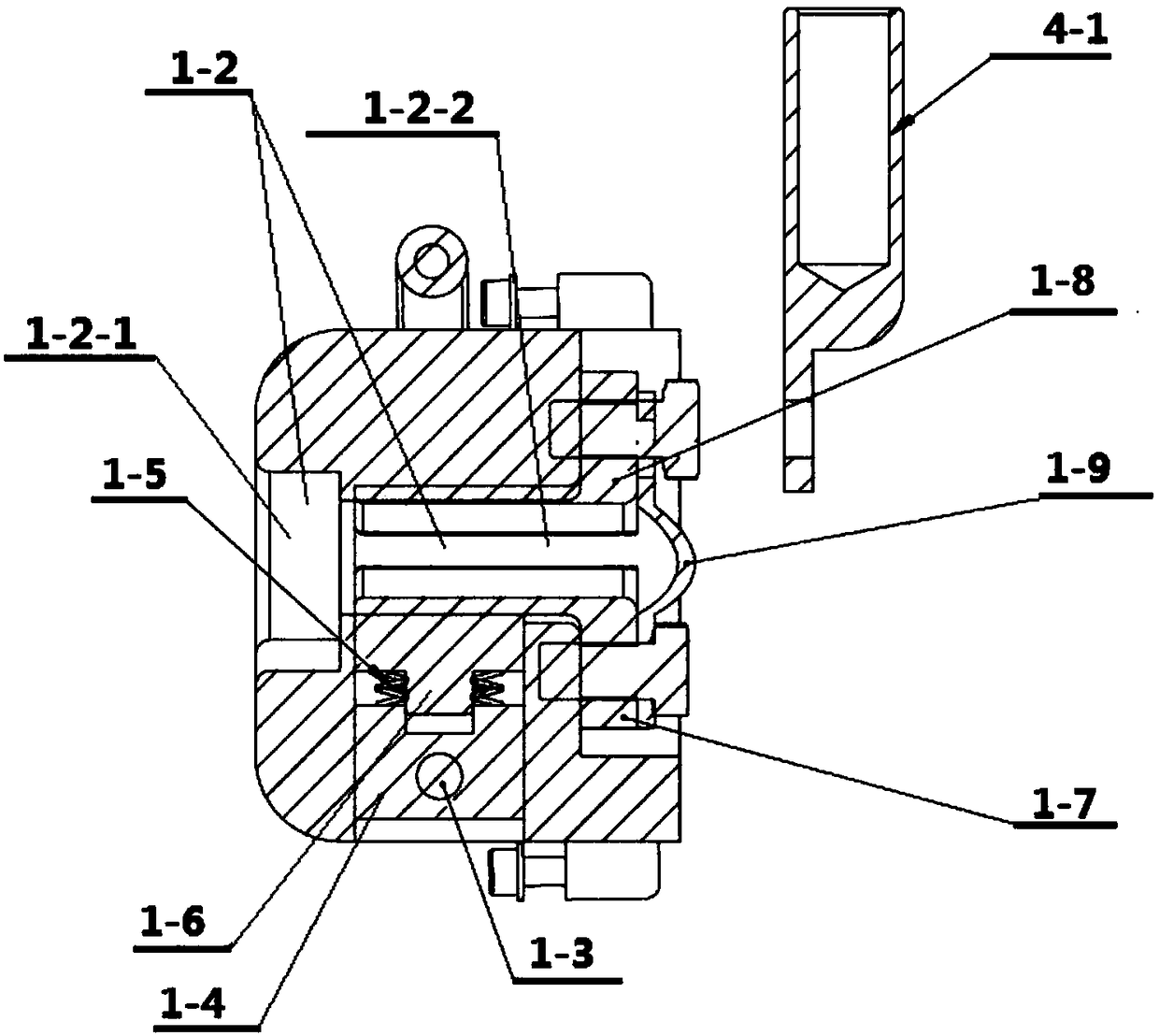

[0022] see Figure 1 to Figure 3 , the fast interface device for transporting super-large current of the present invention includes a seat body 1, the seat body 1 is provided with an insulating shell 1-1, and the side wall of the seat body 1 is provided with a horizontal plug port 1-2, and the horizontal plug port The bottom and top of 1-2 are respectively equipped with a first electrode block 1-7-2 and a third electrode block 1-8-2 connected to an external power supply, and the bottom of the third electrode block 1-8-2 is provided with a plug The first arc-shaped guide groove 1-8-1 matched with the side wall of the plug, the third electrode block 1-8-2 is provided with four first screw holes 121, and the top of the insulating shell 1-1 is provided with four A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com