Automatic mine switch

An automatic switch and mine-used technology, which is applied in the direction of electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve unsatisfactory problems, meet the requirements of electricity consumption, and increase the rated working voltage and current level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

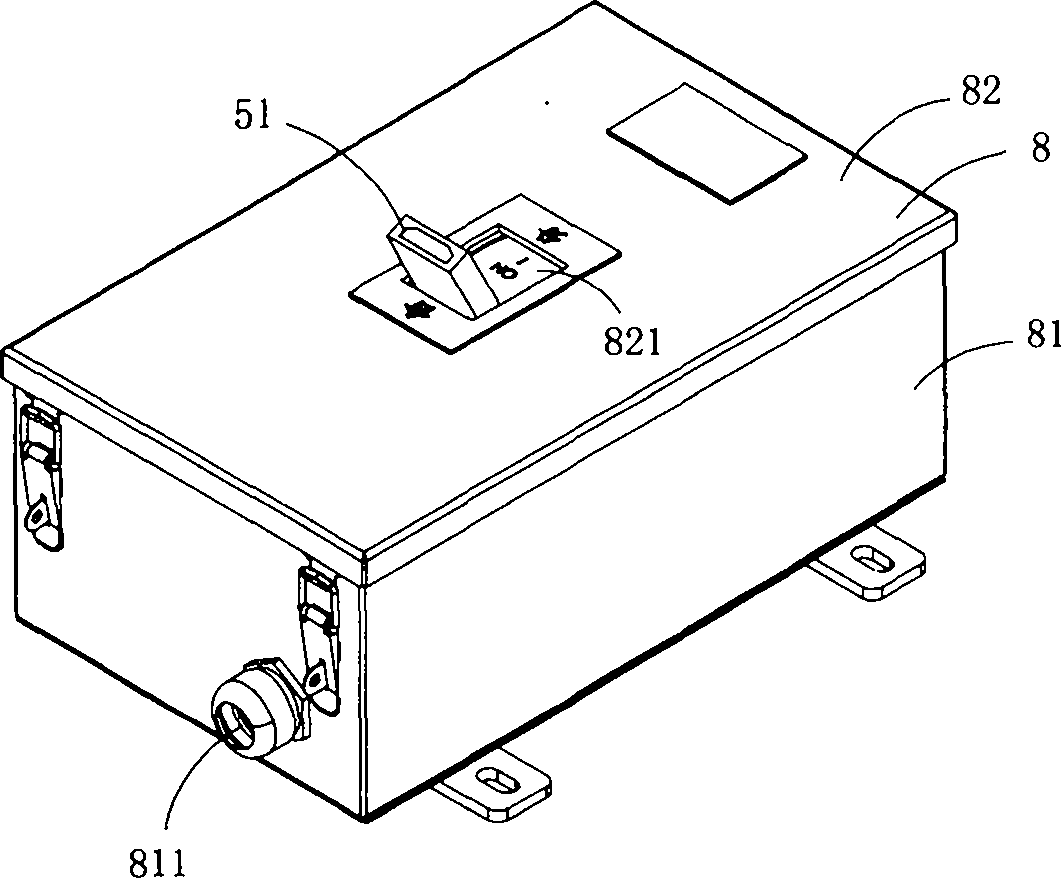

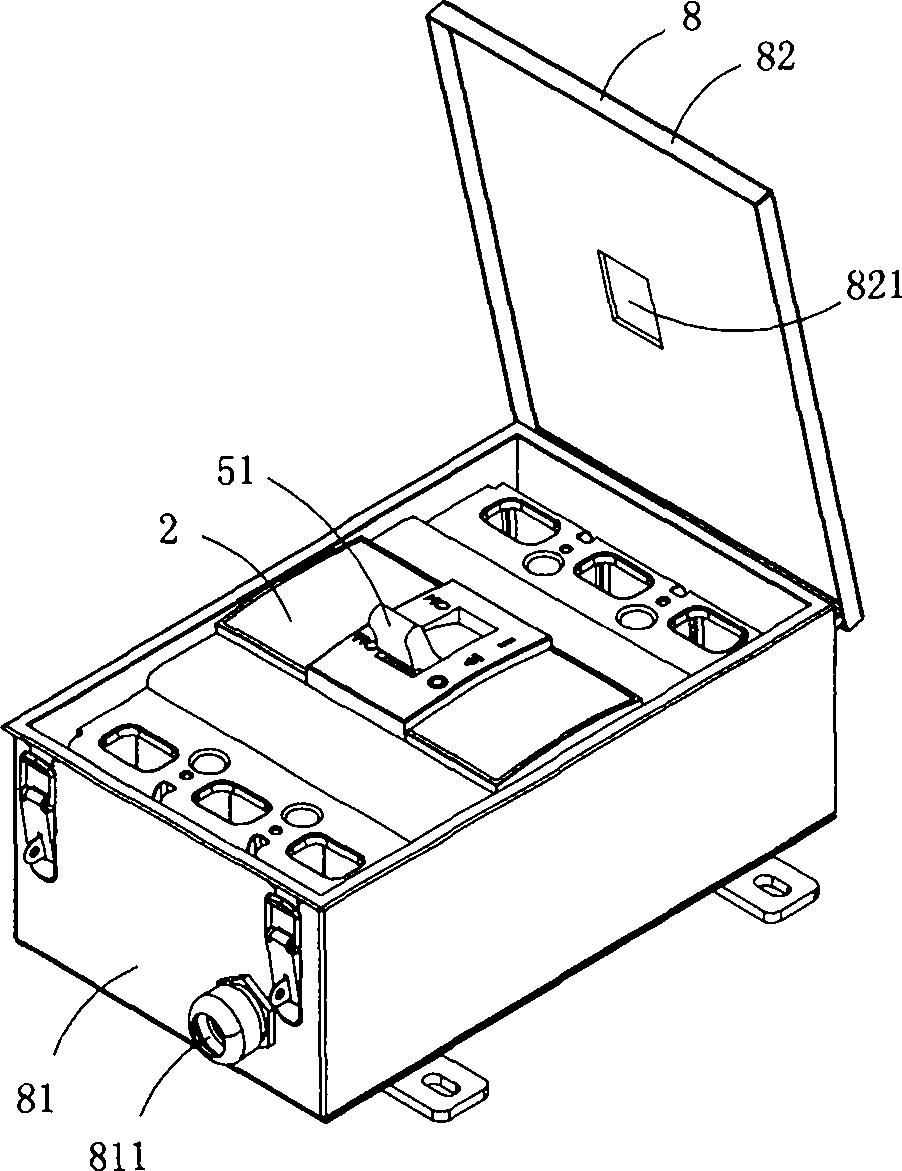

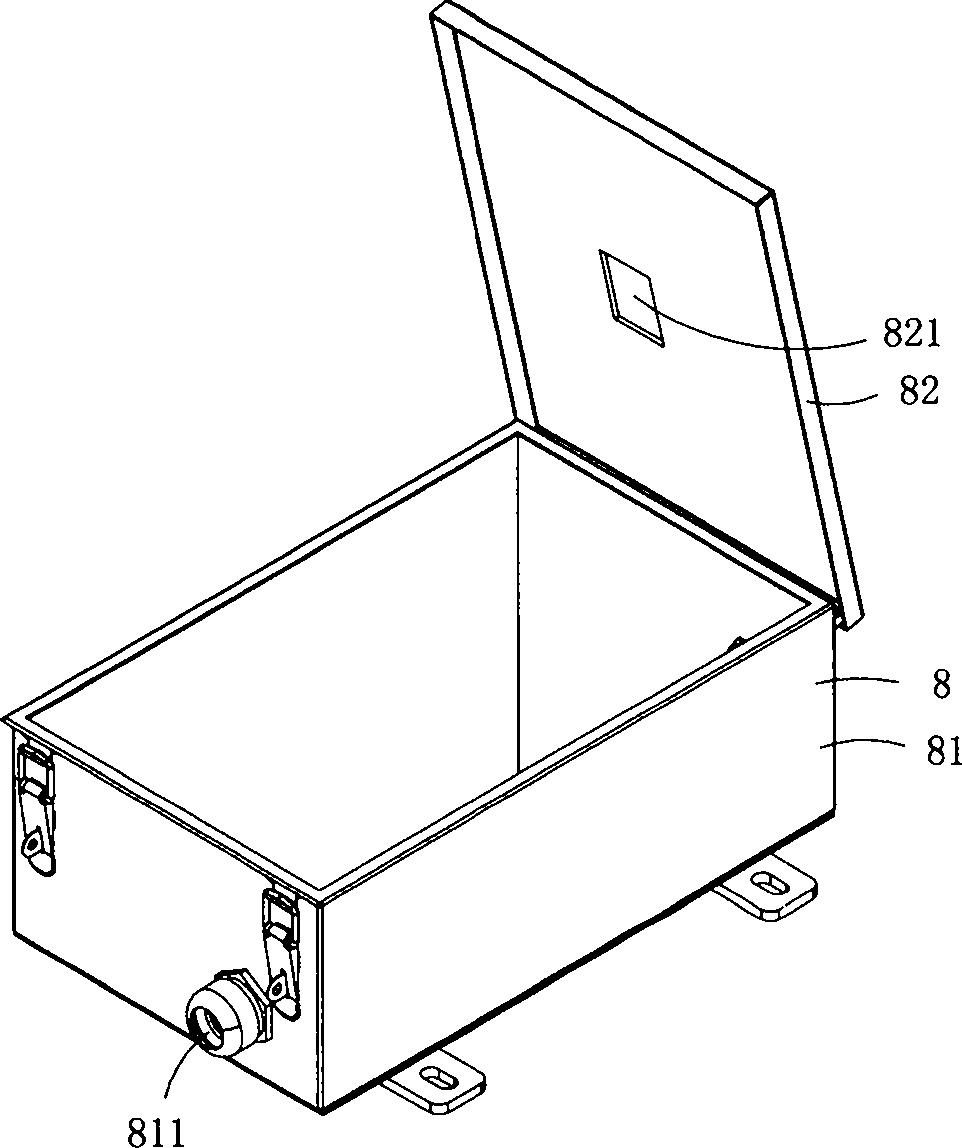

[0016] Figure 1 to Figure 4 A first embodiment of the invention is shown, in which figure 1 It is a schematic diagram of a three-dimensional structure of the first structure of the present invention; figure 2 Yes figure 1 A schematic diagram of a three-dimensional structure when the mine automatic switch is in an open state; image 3 Yes figure 1 A schematic diagram of a three-dimensional structure of the metal box in the mine automatic switch shown; Figure 4 Yes figure 1 A schematic diagram of a three-dimensional structure of the mine automatic switch shown after the metal box is removed.

[0017] This embodiment is an automatic switch, see Figure 1 to Figure 4 As shown, it includes a plastic base 1, a plastic upper cover 2, a wiring assembly 3 arranged on the base 1, a contact system 4, an operating mechanism 5, an arc extinguishing mechanism 6, a tripping device 7 and a metal box body 8; the contact The head system includes three static contacts 41 and three movi...

Embodiment 2

[0023] Figure 5 to Figure 7 A second embodiment of the invention is shown, in which Figure 5 It is a schematic diagram of a three-dimensional structure of the second structure of the present invention; Image 6 Yes Figure 5 A schematic diagram of a working state of the mine automatic switch shown; Figure 7 Yes Figure 5 A schematic diagram of the three-dimensional structure of the auxiliary wrench in the mine automatic switch shown.

[0024] This embodiment is basically the same as the first embodiment, the difference is that the operating mechanism also includes an auxiliary wrench 52, and the auxiliary wrench is provided with a socket hole 521 for being sleeved on the handle; The positioning part 9 of the auxiliary wrench is provided with a socket 91, and the auxiliary wrench is inserted into the socket; when manual opening and closing is required, the auxiliary wrench is connected to the handle, and the opening and closing can be performed in a very labor-saving man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com