Method for Actuating a Valve

A solenoid valve, current technology, applied in the direction of valve operation/release device, valve detail, valve device, etc., can solve the problems of fluid column deceleration, noise increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

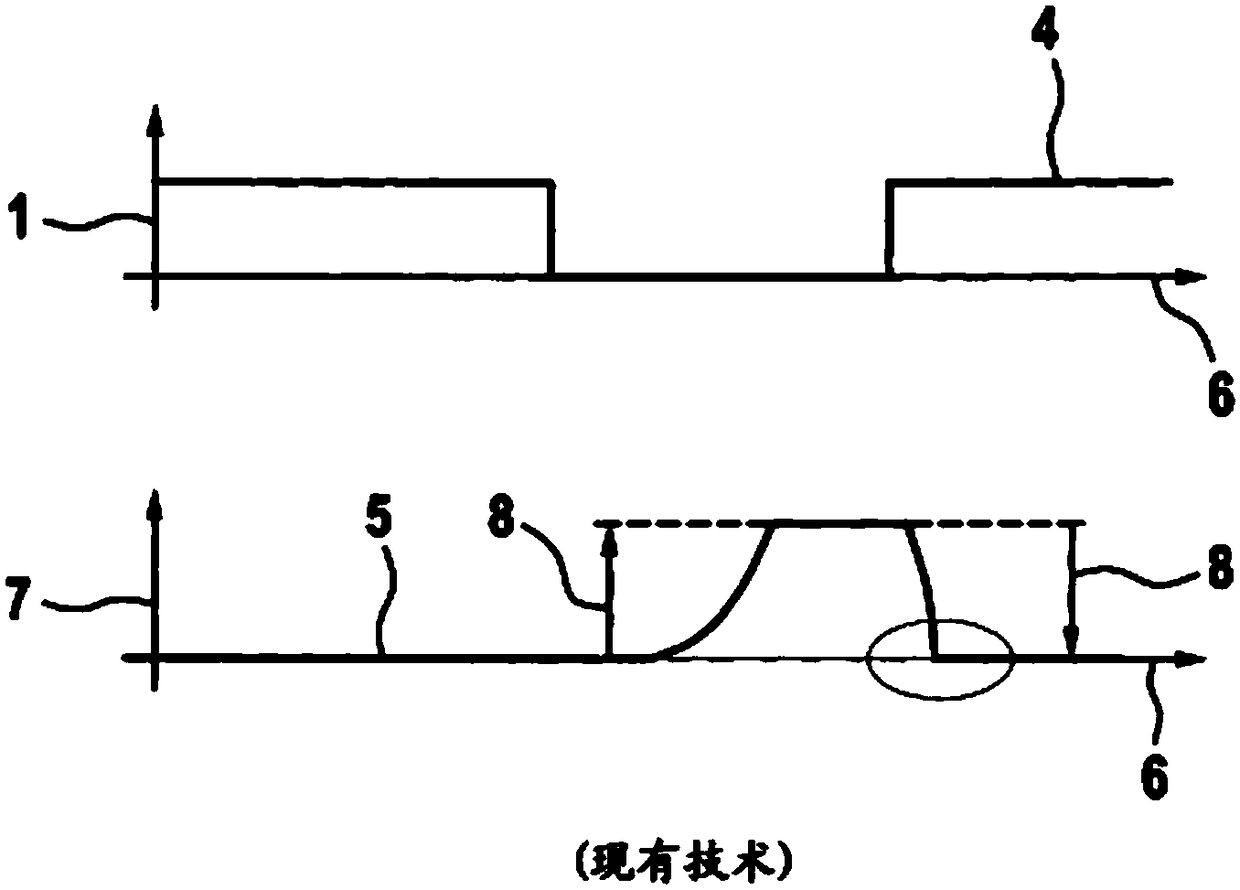

[0032] figure 1 An (idealized) current profile 4 with an associated (idealized) valve position profile 5 according to the prior art is shown schematically. according to figure 1 , the curve of the current 1 over time 6 is plotted in the upper part, and the curve of the valve position 7 over time 6 is plotted in the lower part. From the profile of the valve position 7 it can be seen that the valve is completely closed at the height of the abscissa. for further description figure 1 The current variation curve 4 and the valve position variation curve 5 in , refer to the above-mentioned embodiment for the prior art.

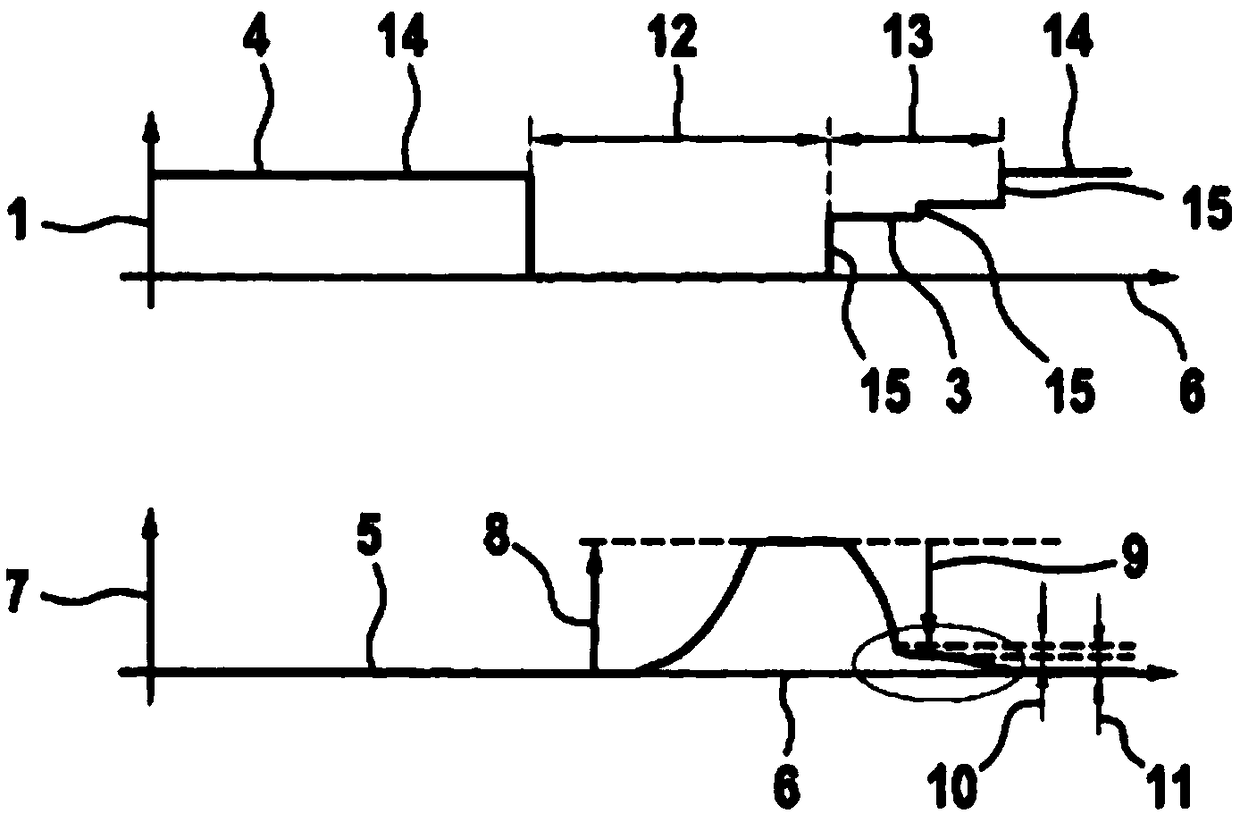

[0033] figure 2 The (idealized) current profile 4 with the associated (idealized) valve position profile 5 produced in the method according to the invention is shown schematically. also according to figure 2 , the curve of the current 1 over time 6 is plotted in the upper part, and the curve of the valve position 7 over time 6 is plotted in the lower part. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com