Automatic cooling constant-temperature cup

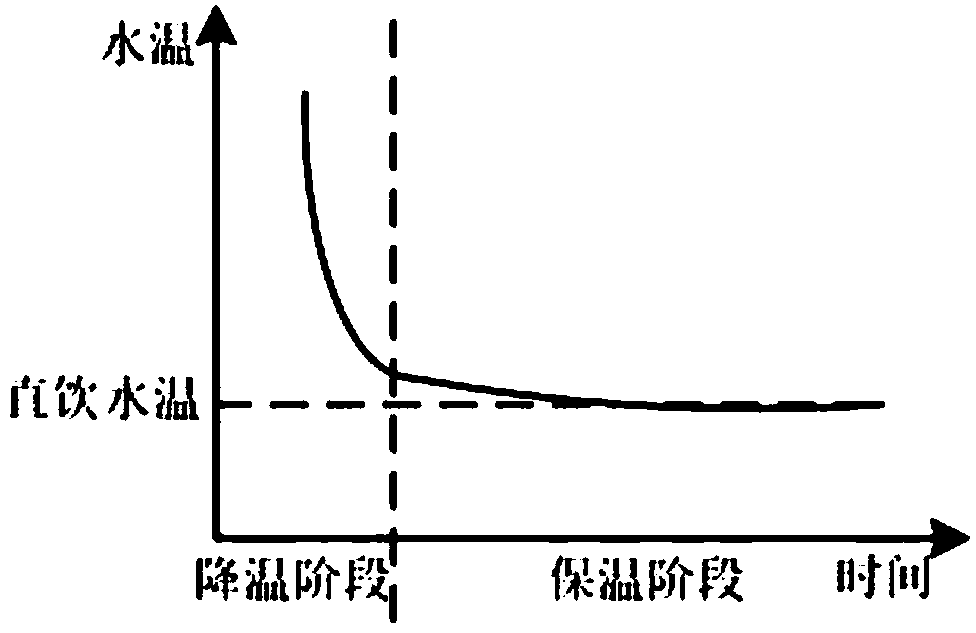

An automatic cooling and constant temperature technology, which is applied in the direction of drinking water containers, etc., can solve the problems of increasing the overall cup body volume, hot water scalding, safety hazards, etc., to avoid scalding, speed up heat dissipation, and meet the effect of instant drinking hot water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

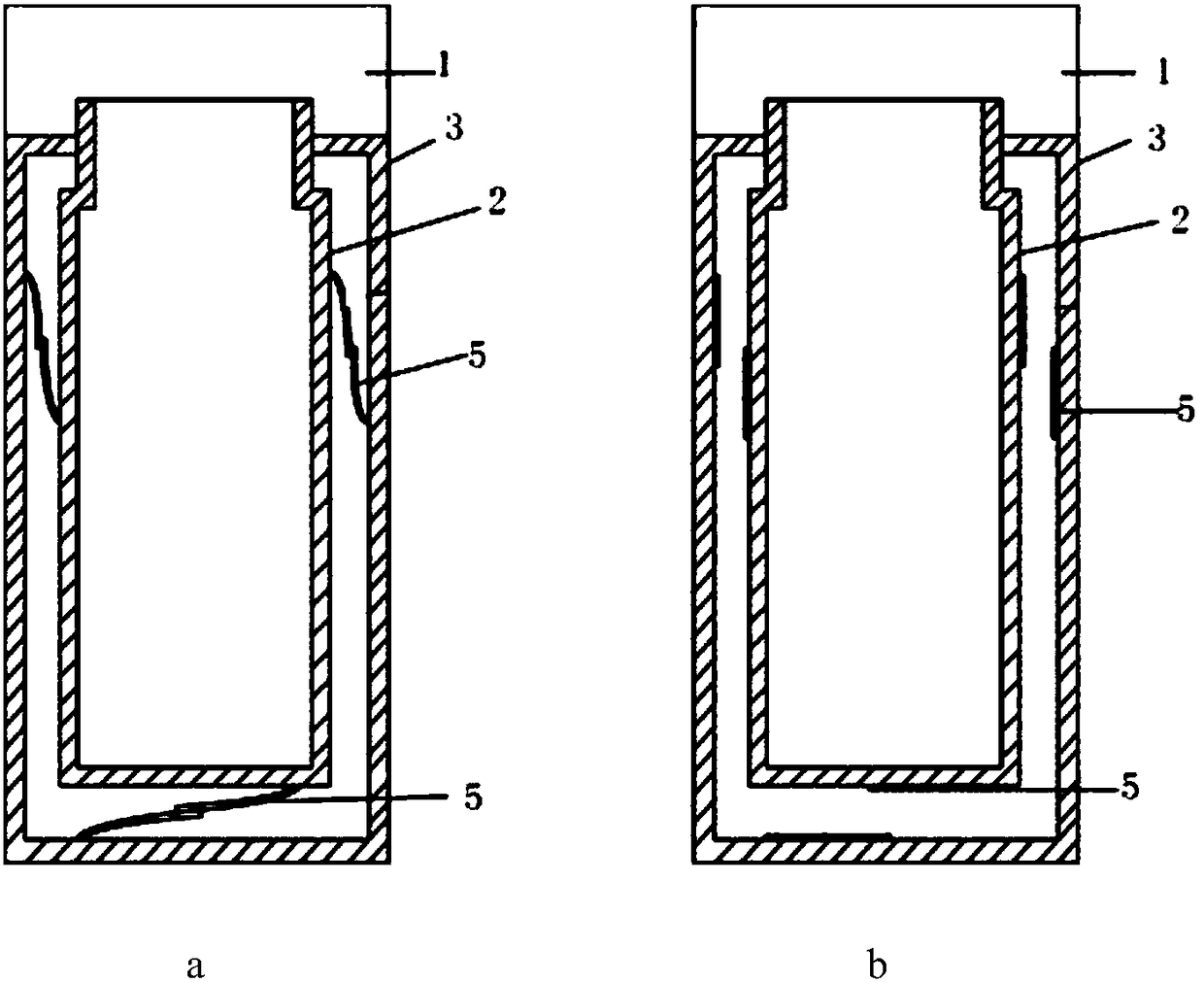

[0021] see Figure 1-Figure 3 , an automatic cooling constant temperature cup, including an outer cup body 3, an inner cup body 2 and a heat conduction sheet 5; both the outer cup body 3 and the inner cup body 2 are hollow tubular structures with one side opening, and the outer cup body 3 is sleeved inside The outside of the cup body 2, and the inner wall of the opening of the outer cup body 3 and the outer wall of the opening of the inner cup body 2 are sealed; a vacuum insulation chamber is formed between the outer cup body 3 and the inner cup body 2; several heat conduction chambers are arranged in the vacuum insulation chamber sheet 5, the heat conduction sheet 5 connects the outer cup body 3 and the inner cup body 2.

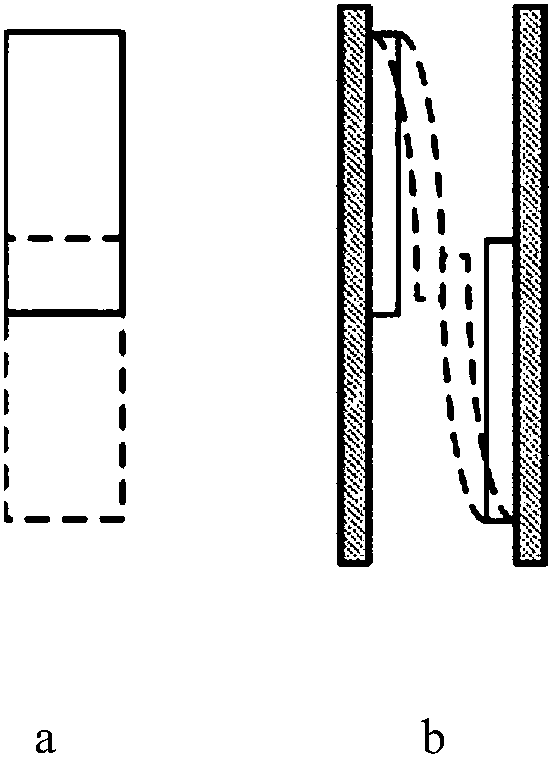

[0022] The heat conduction sheet 5 is a bimetal sheet structure; one end of a bimetal sheet is arranged on the inner cup body 2, and one end of the other bimetal sheet is arranged on the outer cup body 3. When boiling water is poured into the cup, the two b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com