Pin anti-falling structure for producing automobile part mold

An auto parts, anti-falling technology, applied to vehicle parts, molding tools, manufacturing tools, etc., can solve the problems of easy falling off of pins, damage to working parts of molds, and abnormal production of molds, so as to achieve the effect of not falling off easily and ensuring normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further connect the purpose, effect and technical means of the present invention, the specific description is as follows in conjunction with the accompanying drawings.

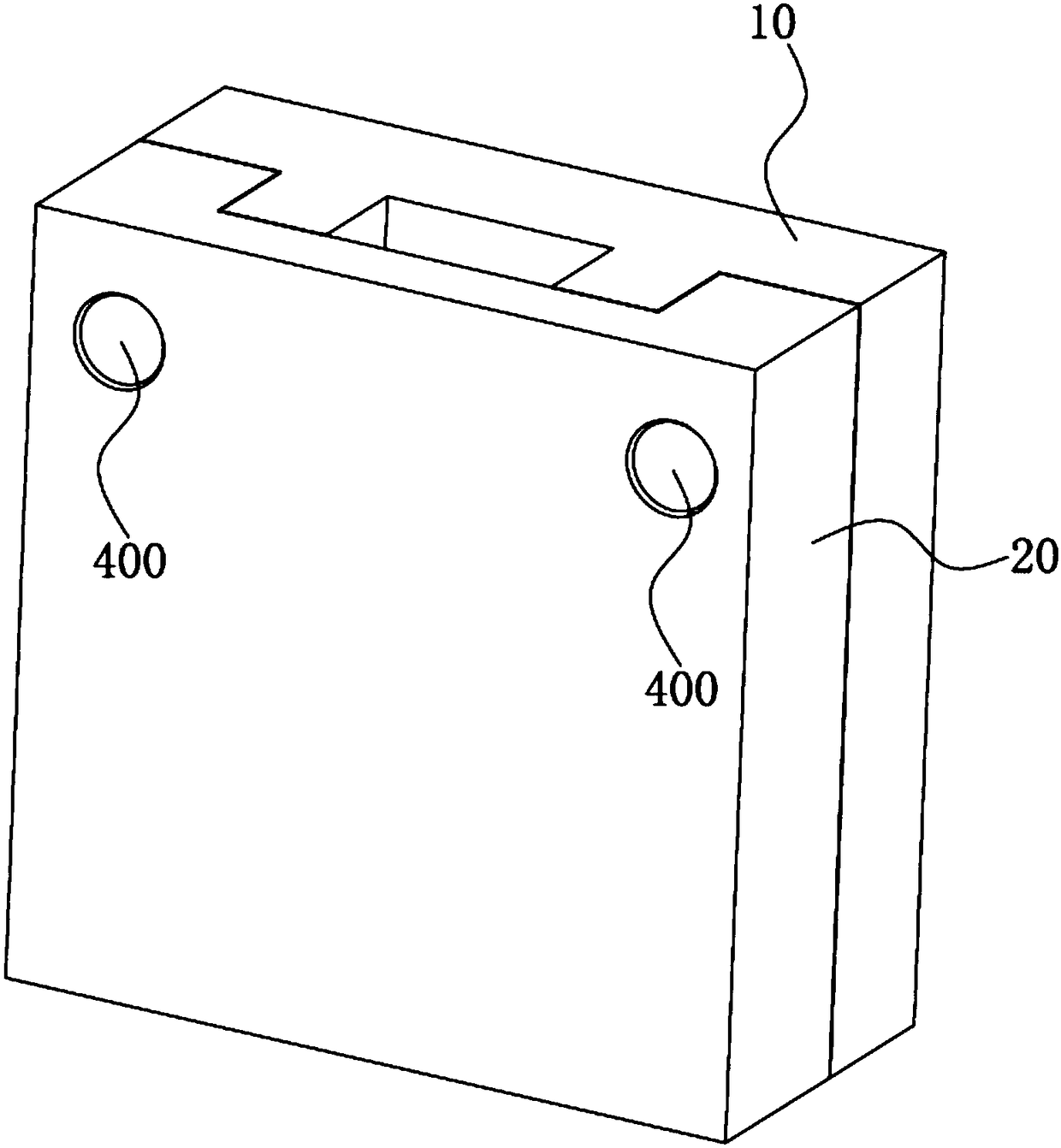

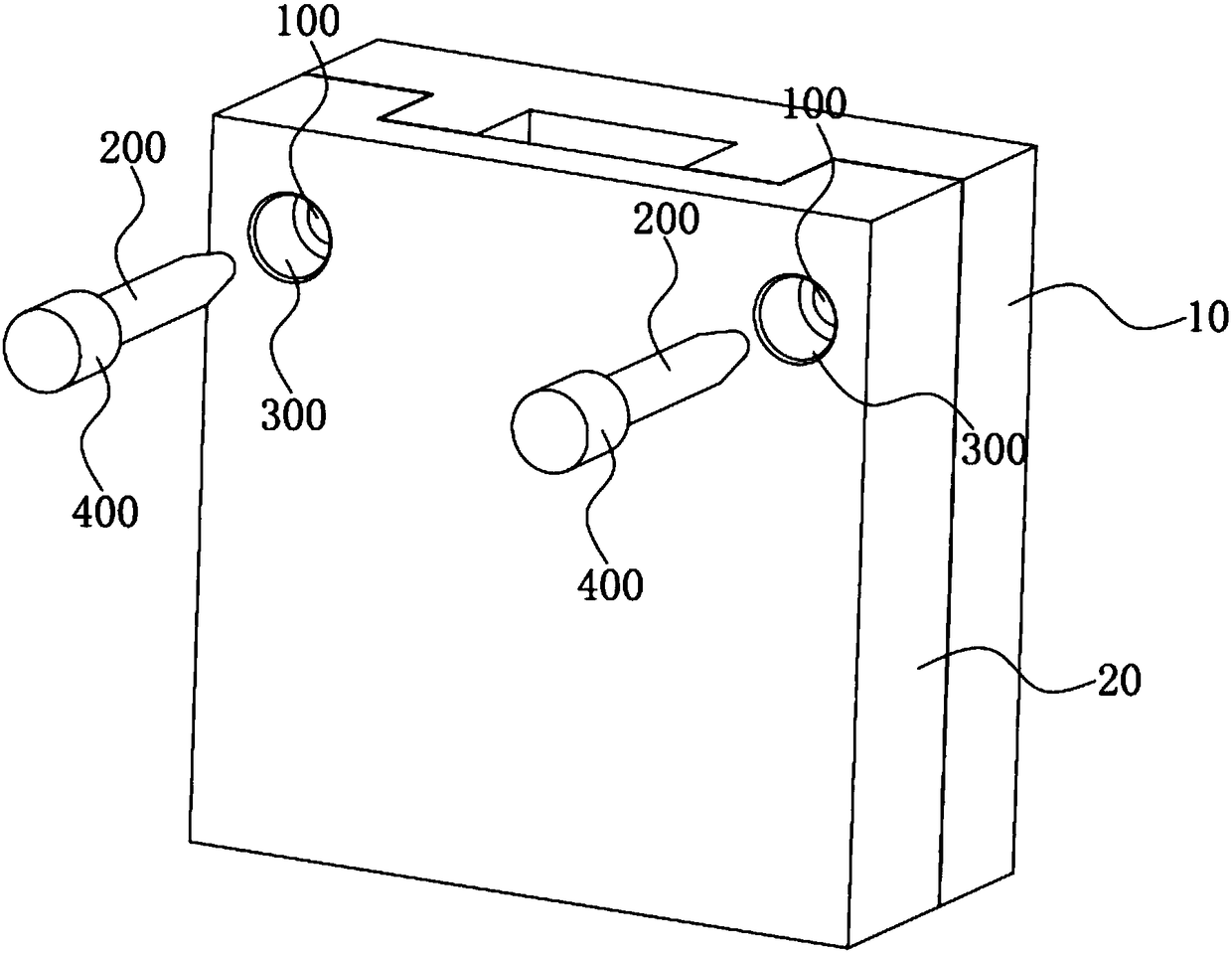

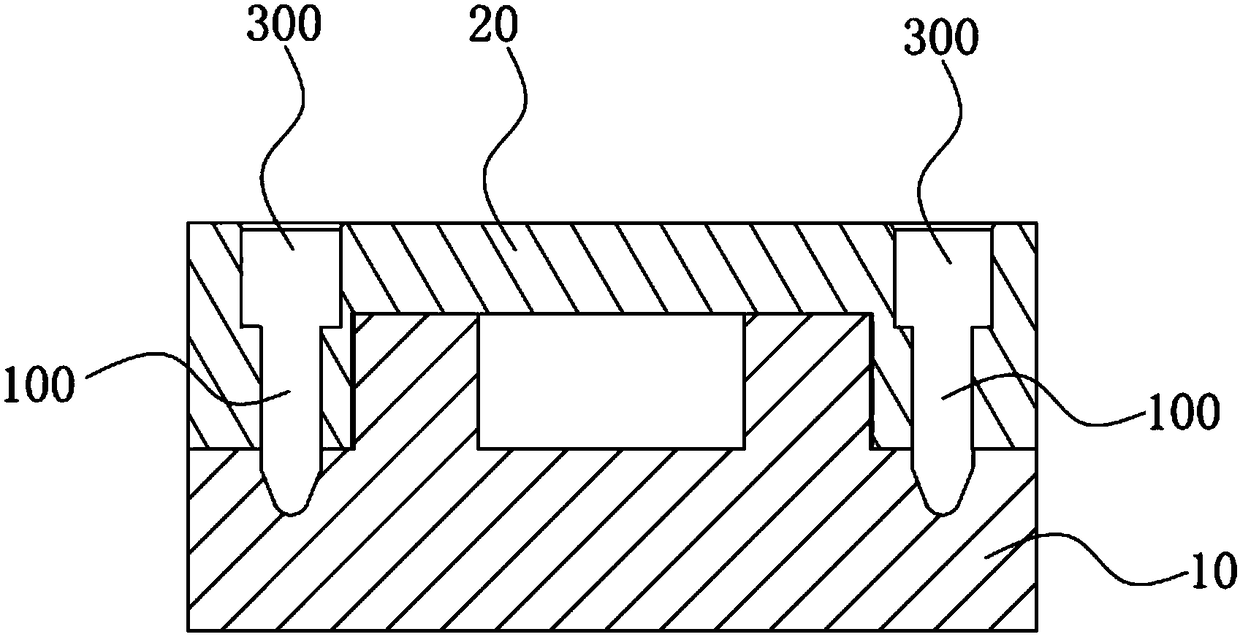

[0023] see Figure 1 to Figure 3 shown, where figure 1 The three-dimensional schematic diagram of the anti-dropping structure of the pins of the automobile parts mold produced by the present invention is depicted, figure 2 Draw the exploded schematic diagram of the pin anti-falling off structure of the production automobile part mold of the present invention, image 3 A cross-sectional view of the pin fall-off preventing structure of the mold for producing automobile parts is shown.

[0024] In this embodiment, the pin fall-off prevention structure of the mold for producing automobile parts of the present invention is applied to the production of automobile parts in the mold, and the pin fall-off prevention structure includes:

[0025] The pin hole 100 runs through the first part 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com