Spiral conveying device

A spiral conveying device, spiral technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve problems such as low efficiency, excessive product speed, and large product wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

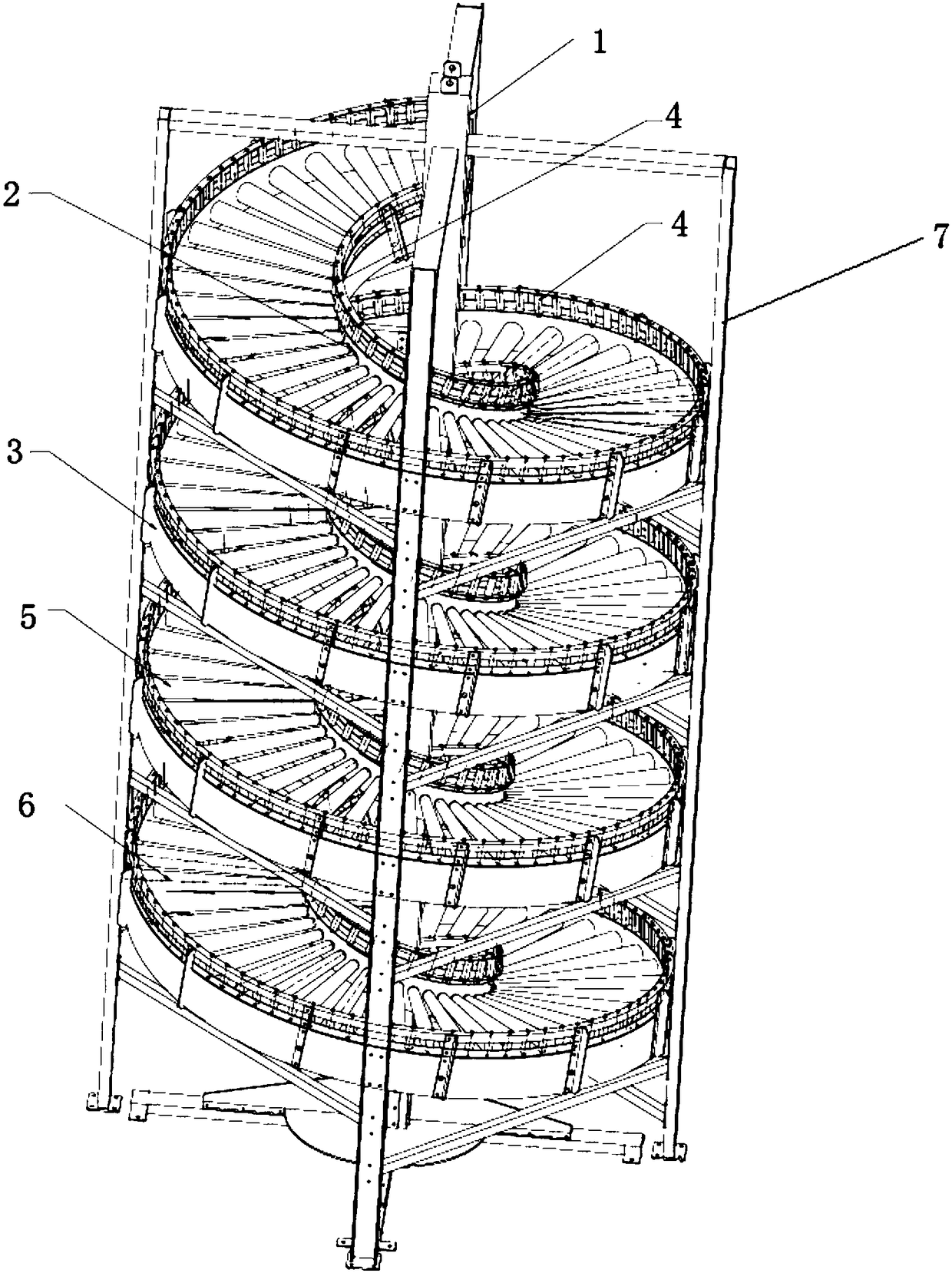

[0024] A kind of screw conveying device, its structure is as figure 1 As shown, it includes a support and a four-layer spiral conveying channel fixedly installed on the support. The conveying channel is provided with evenly distributed rollers. The rollers include free rollers 5 and damping rollers 6 that are evenly and spaced in the free rollers 5. There are two magnetic damping rollers 6 on one layer of conveying channel, and the two magnetic damping rollers are respectively arranged in the middle and tail of each layer of conveying channel. Exit to leave. By setting the damping roller 6 in the free roller 5, when the workpiece passes above the free roller 5, due to the gravity of the workpiece itself, it will accelerate and slide forward under the action of the free roller 5, so the speed of the workpiece gradually increases; When passing above the damping roller 6, since the damping roller 6 has greater resistance when rolling, it will hinder the advancement of the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com