Goods shelf transition device for conveying system

A technology for conveying systems and shelves, applied in the field of conveying systems, can solve problems such as poor stability of hooks, loss of shelves falling, and falling of shelves, and achieve the effect of small sliding friction and improved positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

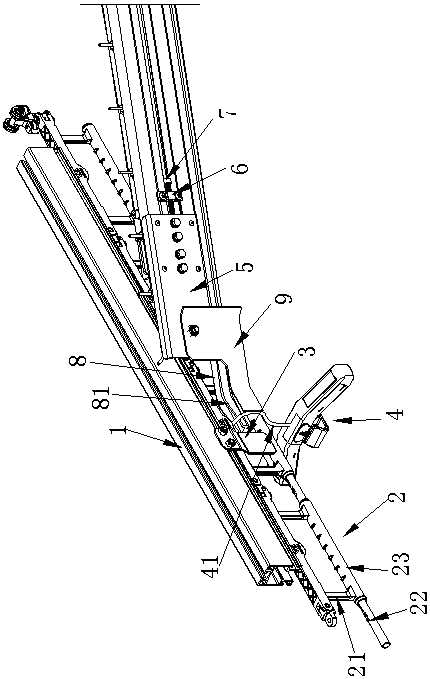

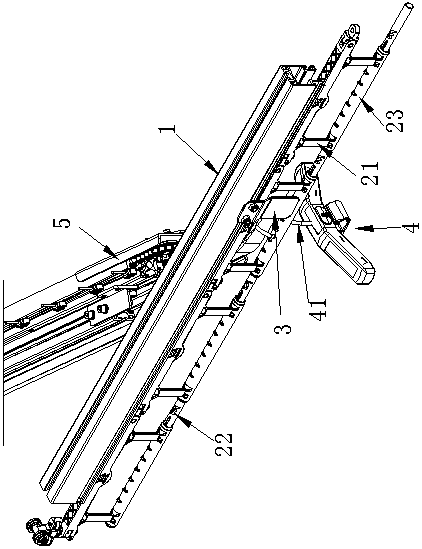

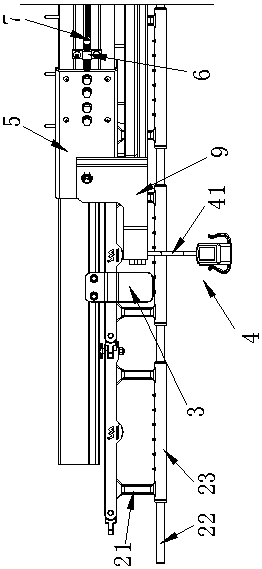

[0019] With reference to the drawings in the description, the rack switching device of the conveying system is arranged between the screening line and the feeding line, and includes a feeding rod 8 formed on the outlet end side of the feeding line. There is a articulated part on the screening line where the supply rack is articulated. There is an angle between the feeding rod 8 and the screening line. The outlet end of the feeding rod 8 extends to the screening line on the upper side of the articulated part. After the outlet end of the rod 8 comes out, it drops and is hooked on the hooking portion. Limiting plates 3 are arranged in pairs near the position of the outlet end of the feeding rod 8 on the screening line, and there is an interval between the outlet end of the feeding rod 8 and the limiting plate 3. 8 up and down onto the hitch.

[0020] The two limiting plates 3 in a pair are arranged on opposite sides of the screening line, the limiting plates 3 are arranged along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com